Multi-level precise surface treatment preventive maintenance method

A preventive maintenance and surface finishing technology, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve the problem of driving safety, poor adhesion with the original road, slurry seal and micro-surface. Noise and other problems, to facilitate the promotion and application, repair minor cracks, reduce the effect of water seepage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

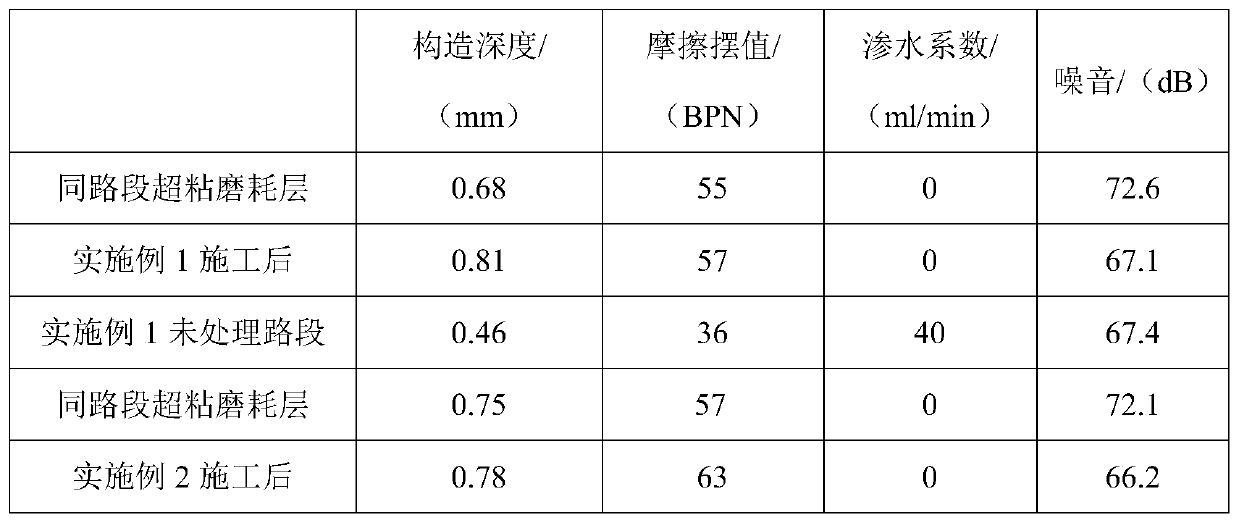

Embodiment 1

[0021] The quick-drying asphalt pavement penetrating regeneration maintenance agent of this embodiment includes the following raw materials: 10 parts of SMC asphalt modifier, 20 parts of hard asphalt particles, 5 parts of 8#-12 aromatic rubber oil, and 40 parts of methylene chloride.

[0022] The light-curing water-based epoxy wear-resistant agent includes the following raw materials: 100 parts of emulsified asphalt, 30 parts of light-curing water-based epoxy resin, 1 part of organosilane coupling agent, and 5 parts of barium sulfate.

[0023] Resin liquid asphalt includes water-based polyurethane latex, neoprene latex and SBS emulsified asphalt with a mass ratio of 1:1:1.

[0024] Among them, the resin liquid asphalt and anti-wear agent are heated to 50°C in the equipment in advance when spreading.

[0025] The conservation method of this embodiment comprises the steps:

[0026] (1) Pavement base surface treatment: fill and level the local potholes on the original road surfa...

Embodiment 2

[0035] The quick-drying asphalt pavement penetrating regeneration maintenance agent of this embodiment includes the following raw materials: 20 parts of SMC asphalt modifier, 30 parts of hard asphalt particles, 10 parts of 8#-24 aromatic rubber oil, and 50 parts of methylene chloride.

[0036] The light-curing water-based epoxy wear-resistant agent includes the following raw materials: 100 parts of emulsified asphalt, 40 parts of light-curing water-based epoxy resin, 3 parts of organosilane coupling agent, and 10 parts of barium sulfate.

[0037] Resin liquid asphalt includes water-based polyurethane latex, neoprene latex and SBS emulsified asphalt with a mass ratio of 1:1:1.

[0038] Among them, the resin liquid asphalt and anti-wear agent are heated to 60°C in the equipment in advance when spreading.

[0039] The maintenance method includes the following steps:

[0040] (1) Pavement base surface treatment: fill and level the local potholes on the original road surface, and ...

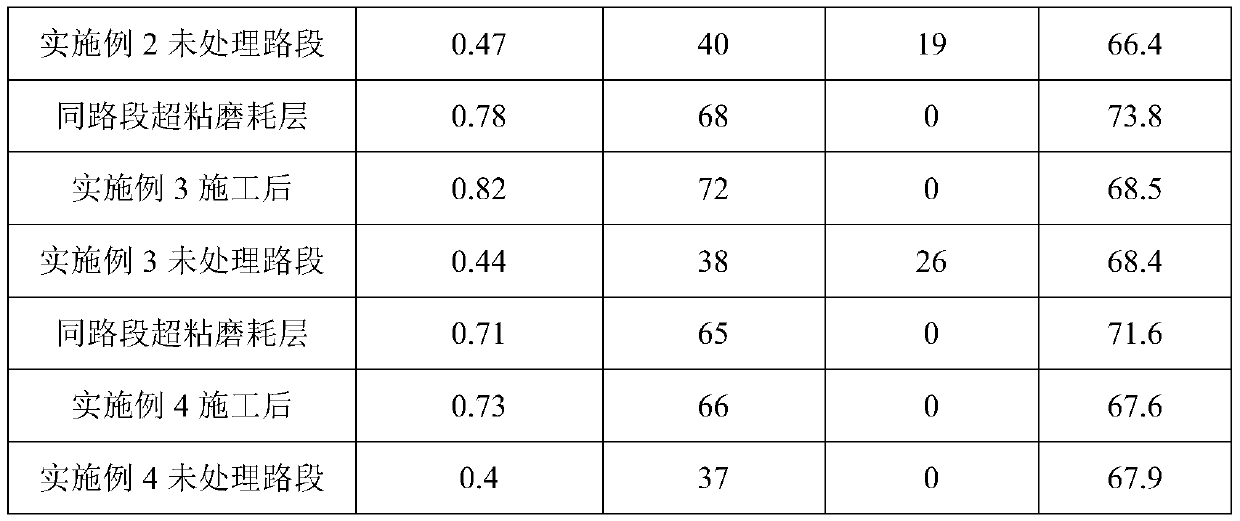

Embodiment 3

[0049] The quick-drying asphalt pavement penetrating regeneration curing agent of this embodiment includes the following raw materials: 15 parts of SMC asphalt modifier, 25 parts of hard asphalt particles, 7 parts of 8#-12 aromatic rubber oil, and 45 parts of methylene chloride.

[0050] The light-cured water-based epoxy wear-resistant agent includes the following raw materials: 100 parts of emulsified asphalt, 36 parts of light-cured water-based epoxy resin, 2 parts of organosilane coupling agent, and 8 parts of barium sulfate wear-resistant agent.

[0051] Resin liquid asphalt includes water-based polyurethane latex, neoprene latex and SBS emulsified asphalt with a mass ratio of 1:1:1.

[0052] Among them, the resin liquid asphalt and anti-wear agent are heated to 70°C in the equipment in advance when spreading.

[0053] The maintenance method includes the following steps:

[0054] (1) Pavement base surface treatment: fill and level the local potholes on the original road s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com