MOS structure trench diode device and manufacturing method thereof

A technology of MOS structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low forward voltage and inability to achieve low and high temperature leakage characteristics, and achieve the concentration and realization of weakened electric field The effect of cutting off surface channel leakage and reducing the requirements of photolithography process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

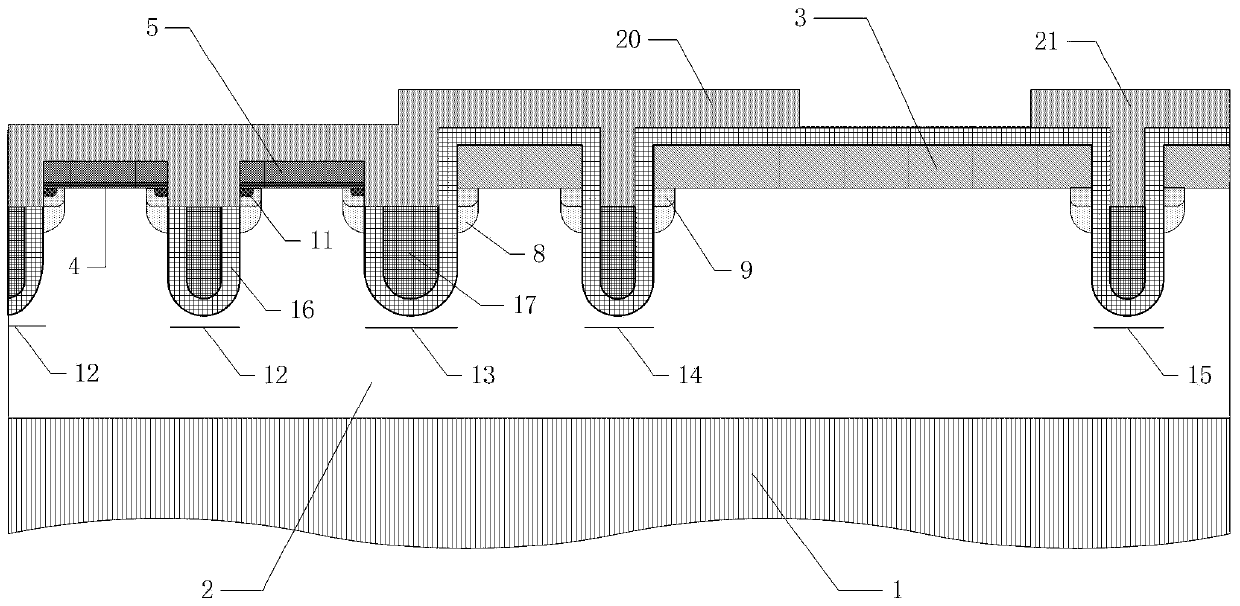

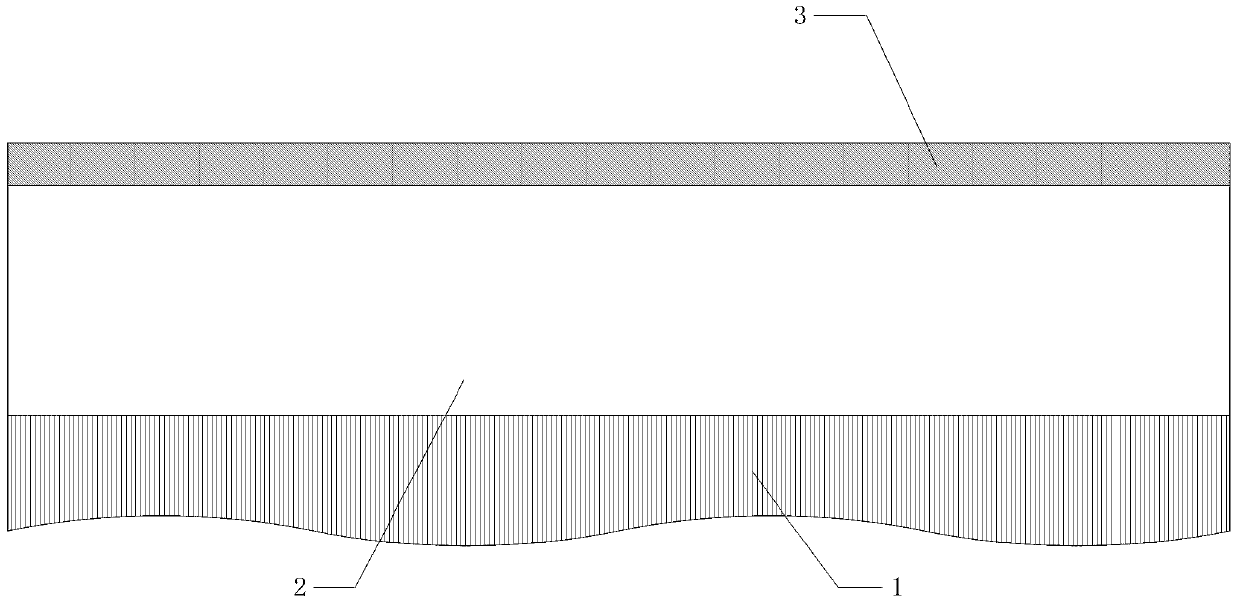

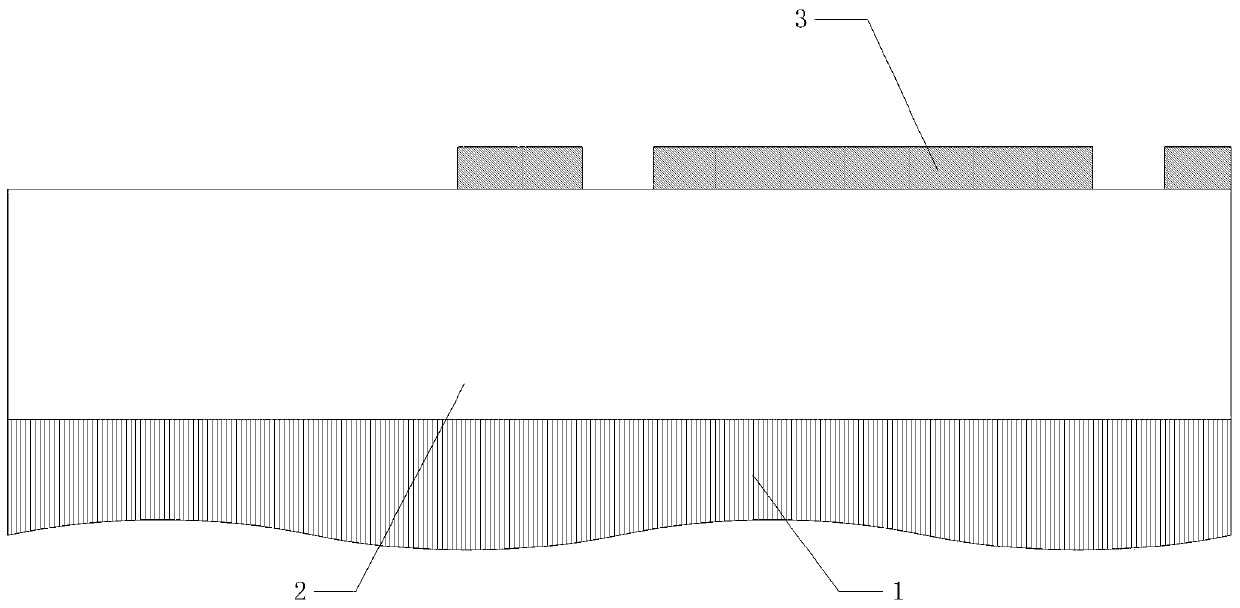

[0088] Specific embodiment 1, see figure 1 , a trench diode device with a MOS structure, comprising a silicon substrate 1 of the first conductivity type and an epitaxial layer 2 of the first conductivity type arranged in sequence from bottom to top, and on the epitaxial layer 2 are arranged sequentially from left to right at least Two original cell grooves 12, a large original cell groove 13, an extension groove 14 and a stop groove 15, the width of the original cell groove 12 is less than the width of the original cell large groove 13; the original cell groove 12, the original cell The inner walls of the large trench 13, the extended trench 14 and the cut-off trench 15 are sequentially provided with a silicon dioxide outer layer 16 and a polysilicon filling layer 17;

[0089] On the epitaxial layer 2, a gate oxide layer 4 (that is, SiO 2 layer), a polysilicon layer 5 of the first conductivity type is provided above the gate oxide layer 4;

[0090] The first doped region 8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com