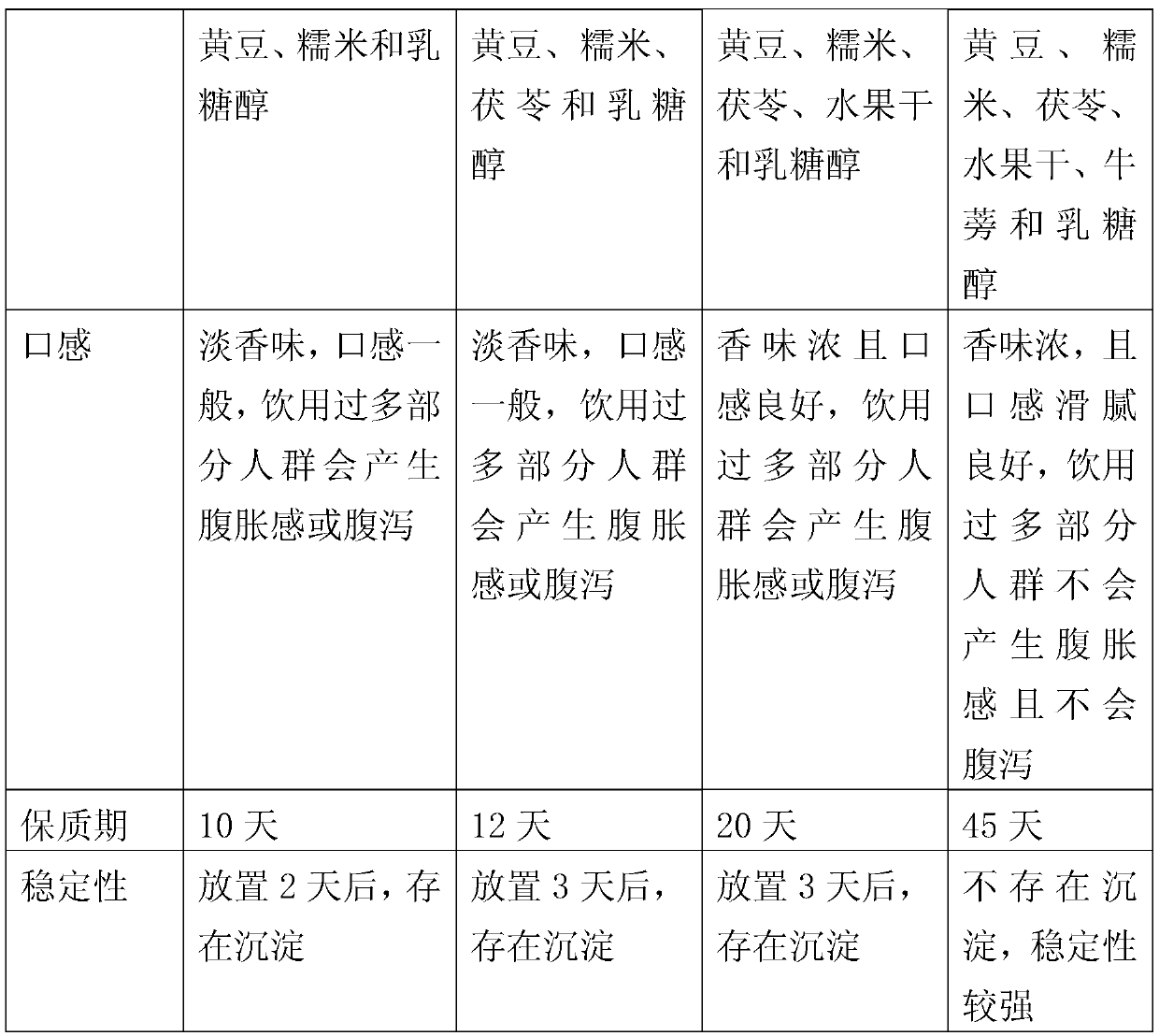

Composite soybean milk and preparation process thereof

A production process and technology of soy milk, applied in dairy products, milk substitutes, applications, etc., can solve the problems of short shelf life, inability to promote iron absorption, human harm of defoaming agents, etc., achieve strong antioxidant effect, relieve indigestion, precipitation, etc. Phenomenon elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

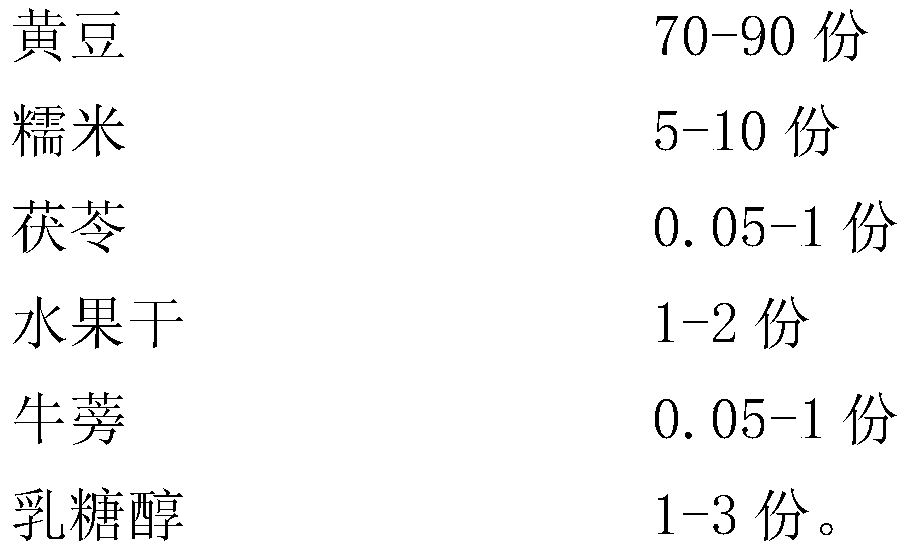

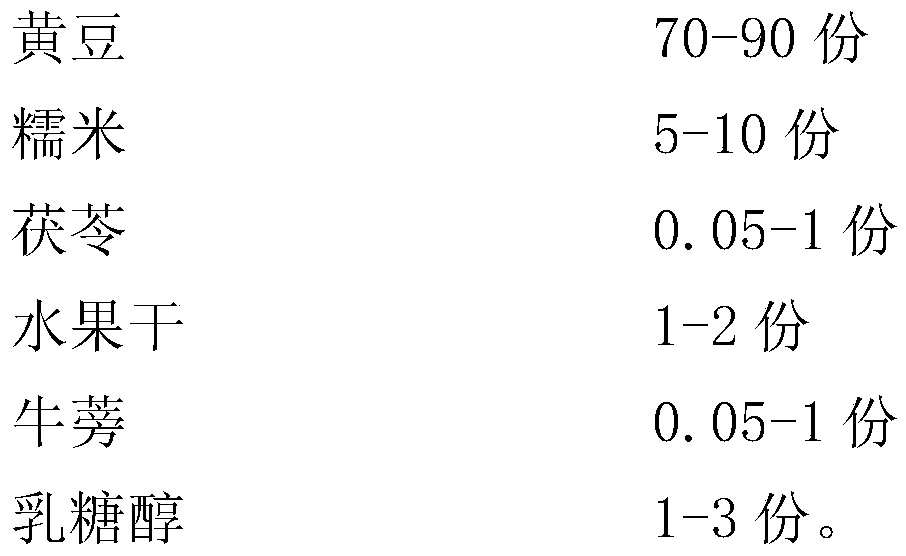

[0037] The compound soybean milk of the present embodiment comprises the following components by weight:

[0038]

[0039]

[0040] The dried fruit is a mixture selected from dried ginseng fruit, dried snow lotus fruit and dried peach.

[0041] The dried fruit is picked fresh fruit and dried by a dryer, and the water activity of the dried fruit after drying is less than 0.7.

[0042] The pH value of the soybean milk is 5.0.

[0043] The lactitol is a mixture of lactitol monohydrate and lactitol dihydrate.

[0044] The manufacturing process of the compound soybean milk which can prolong the shelf life of soybean milk comprises the following steps:

[0045] 1), adopt peeling machine to carry out peeling to above-mentioned soybean by weight, after cleaning the soybean after peeling, soak for 12 hours;

[0046] 2) Grinding the soybeans obtained in step 1) to obtain the first soy milk slurry and the first okara, adding water to the first okara and performing secondary grindi...

Embodiment 2

[0054] The compound soybean milk of the present embodiment comprises the following components by weight:

[0055]

[0056] The dried fruit is a mixture selected from dried ginseng and dried peaches.

[0057] The dried fruit is picked fresh fruit and dried by a dryer, and the water activity of the dried fruit after drying is less than 0.7.

[0058] The pH value of the soybean milk is 6.1.

[0059] The lactitol is lactitol monohydrate.

[0060] The manufacturing process of the compound soybean milk which can prolong the shelf life of soybean milk comprises the following steps:

[0061] 1), adopt peeling machine to carry out peeling to above-mentioned soybean by weight, soak 24 hours after cleaning the soybean after peeling;

[0062] 2) Grinding the soybeans obtained in step 1) to obtain the first soy milk slurry and the first okara, adding water to the first okara and performing secondary grinding to obtain the second soy milk slurry and the second okara, combining the fir...

Embodiment 3

[0070] The compound soybean milk of the present embodiment comprises the following components by weight:

[0071]

[0072] The dried fruit is one or a mixture of dried ginseng, dried yacon and dried peaches.

[0073] The dried fruit is picked fresh fruit and dried by a dryer, and the water activity of the dried fruit after drying is less than 0.7.

[0074] The pH value of the soybean milk is 5.5.

[0075] The lactitol is lactitol dihydrate.

[0076] The manufacturing process of the compound soybean milk which can prolong the shelf life of soybean milk comprises the following steps:

[0077] 1), adopt peeling machine to carry out peeling to above-mentioned soybean by weight, after cleaning the soybean after peeling, soak for 12-24 hours;

[0078] 2) Grinding the soybeans obtained in step 1) to obtain the first soy milk slurry and the first okara, adding water to the first okara and performing secondary grinding to obtain the second soy milk slurry and the second okara, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com