Fireproof coating for steel structure as well as preparation method and application of fireproof coating

A technology for fire-resistant coatings and steel structures, applied in the direction of fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor appearance decoration, rough surface, unsuitable for coating and protection of exposed steel structures, etc., and achieve convenient use of coatings The effect of environmental protection and strong fireproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

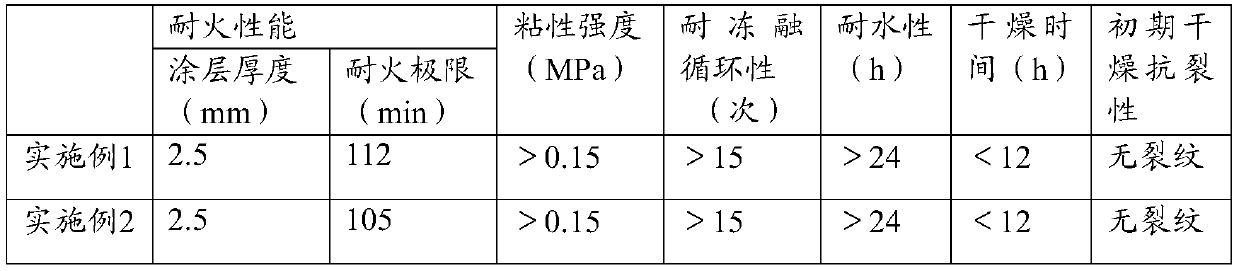

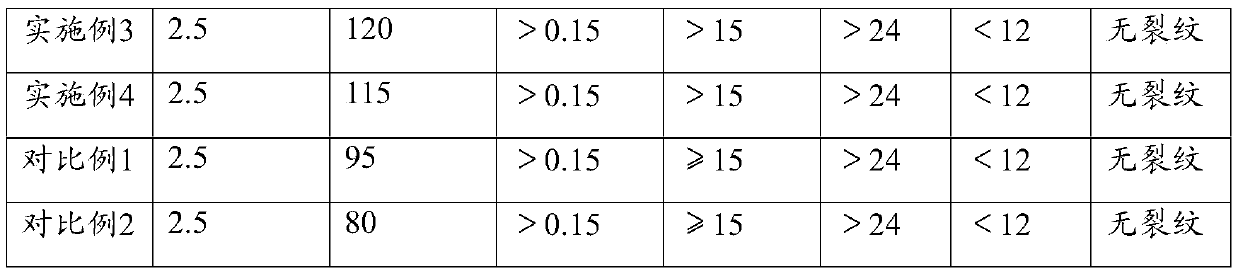

Examples

Embodiment 1

[0026] A fireproof coating for steel structures, comprising the following components by weight: 30 parts of acrylic resin, 15 parts of ammonium polyphosphate and melamine phosphate, 5 parts of dipentaerythritol, 6 parts of chlorinated paraffin, 5 parts of polyol phosphate, carboxymethyl 3 parts of cellulose, 3 parts of aluminum hydroxide, 1 part of carbon nanotube, 1 part of basalt fiber, and 10 parts of water; wherein, the diameter of basalt fiber is 7-9 μm and the length is 0.5-1 mm; the carbon nanotube is multi-walled carbon nano Tube material; the mass ratio of ammonium polyphosphate and melamine phosphate is 3:1.

[0027] The preparation method of above-mentioned steel structure fireproof coating, comprises the following steps:

[0028] S1. Weigh the components by weight: 30 parts of acrylic resin, 15 parts of ammonium polyphosphate and melamine phosphate, 5 parts of dipentaerythritol, 6 parts of chlorinated paraffin, 5 parts of polyol phosphate, 3 parts of carboxymethyl ...

Embodiment 2

[0032] A fireproof coating for steel structures, comprising the following components by weight: 50 parts of phenolic resin, 20 parts of ammonium polyphosphate, 10 parts of pentaerythritol, 10 parts of melamine, 10 parts of tris (β-chloroethyl) phosphate, carboxymethyl 8 parts of cellulose, 5 parts of aluminum hydroxide, 2 parts of carbon nanotubes, 2 parts of basalt fibers, and 15 parts of water; wherein, the diameter of basalt fibers is 7-9 μm and the length is 0.5-1 mm; the carbon nanotubes are multi-walled carbon nano tube material.

[0033] The preparation method of above-mentioned steel structure fireproof coating, comprises the following steps:

[0034] S1. Weigh the components by weight: 50 parts of phenolic resin, 20 parts of ammonium polyphosphate, 10 parts of pentaerythritol, 10 parts of melamine, 10 parts of tris (β-chloroethyl) phosphate, 8 parts of carboxymethyl cellulose , 5 parts of aluminum hydroxide, 2 parts of carbon nanotubes, 2 parts of basalt fiber, 15 pa...

Embodiment 3

[0038] A fireproof coating for steel structures, comprising the following components by weight: 40 parts of epoxy resin, 18 parts of melamine phosphate, 8 parts of pentaerythritol and dipentaerythritol, 7 parts of dicyandiamide and chlorinated paraffin, tris(dichloropropyl) 9 parts of phosphate ester, 5 parts of carboxymethyl cellulose, 4 parts of aluminum hydroxide, 1.5 parts of carbon nanotube, 1.5 parts of basalt fiber, and 12 parts of water; wherein, the diameter of basalt fiber is 7-9 μm, and the length is 0.5-1 mm; The carbon nanotube is a multi-wall carbon nanotube material; the mass ratio of pentaerythritol and dipentaerythritol is 1:1, and the mass ratio of dicyandiamide and chlorinated paraffin is 1:2.

[0039] The preparation method of above-mentioned steel structure fireproof coating, comprises the following steps:

[0040] S1. Weigh components by weight: 40 parts of epoxy resin, 18 parts of melamine phosphate, 8 parts of pentaerythritol and dipentaerythritol, 7 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com