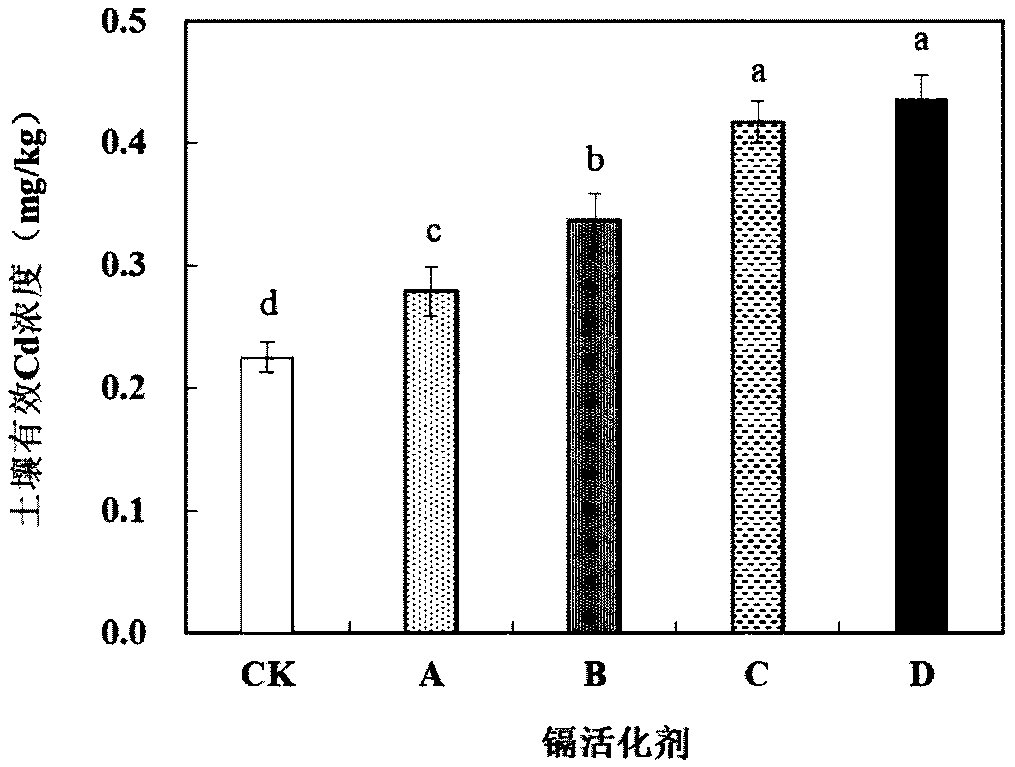

Cadmium activating agent for improving remediation efficiency of cadmium-contaminated soil in solar greenhouse and application thereof

A technology of polluted soil and restoration efficiency, applied in the field of soil restoration, can solve the problems of low restoration efficiency, achieve the effect of simplifying the restoration process, increasing the absolute amount, and highlighting the restoration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The cadmium activator includes 3 parts by weight, 3 parts of glucose, 12 parts of ammonium bicarbonate, 15 parts of urea, 300 parts of sulfur powder, 60 parts of humic acid, 0.3 part of Bacillus megaterium, and 0.3 part of Bacillus subtilis.

[0027] Cadmium activator preparation method:

[0028] (1) According to the above-mentioned parts by weight, glucose, ammonium bicarbonate, urea, sulfur powder, and humic acid were respectively taken, then fully pulverized, passed through a 60-80 mesh sieve, and sieved and mixed uniformly to obtain a mixture;

[0029] (2) adding Bacillus megaterium microbial inoculum and Bacillus subtilis microbial inoculum to the mixture of step (1) and fully mixing;

[0030] The Bacillus megaterium microbial inoculum used in all the examples was purchased from the China Agricultural Microorganism Culture Collection Management Center (No. control center.

[0031] (3) adjusting the mixture of step (2) to water content with distilled water is 8%; ...

Embodiment 2

[0035] The cadmium activator includes 1.5 parts of glucose, 10 parts of ammonium bicarbonate, 10 parts of urea, 200 parts of sulfur powder, 50 parts of humic acid, 0.3 part of Bacillus megaterium, and 0.2 part of Bacillus subtilis in parts by weight.

[0036] (1) According to the above-mentioned parts by weight, glucose, ammonium bicarbonate, urea, sulfur powder, and humic acid were respectively taken, then fully pulverized, passed through a 60-80 mesh sieve, and sieved and mixed uniformly to obtain a mixture;

[0037] (2) adding Bacillus megaterium microbial inoculum and Bacillus subtilis microbial inoculum to the mixture of step (1) and fully mixing;

[0038] (3) adjusting the mixture of step (2) to water content with distilled water is 8%;

[0039] (4) Carry out granulation by extruding granulator, particle diameter is 2mm;

[0040] (5) The product obtained in step (4) is quickly dried in an environment of 40-45° C., and the dried product obtained is passed through a 3 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com