A slow bonding prestressed steel bar and its preparation method

A technology of slow-bonding prestressed and prestressed steel rods, which is applied in the direction of adhesives, structural elements, adhesive types, etc., and can solve the problems of poor compatibility of the main resin, slowing of adhesive peeling, falling off, and large amount of fillers, etc. problems, to achieve the effect of improving high and low temperature alternating performance, improving wettability and dispersibility, and improving high temperature and high humidity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

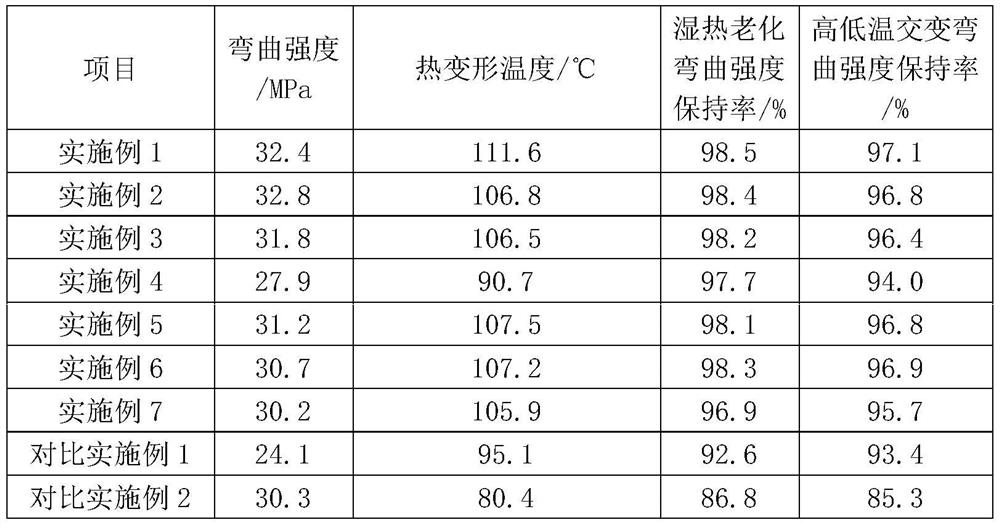

Examples

preparation example 1

[0048] The preparation of preparation example 1 fluorine-containing polyamide

[0049] 1. Add tetrafluorosuccinic acid and tetraethylenepentamine with a molar ratio of carboxyl group to primary amino group of 1:1.2 into the reactor under nitrogen atmosphere, pressurize to 0.3MPa, and stir within 1.5h While raising the temperature to 140°C, the pressure rises to 1.8MPa at this time, keep the pressure constant by intermittently removing the generated water vapor and keep the temperature in the kettle at 150°C for 2 hours;

[0050] 2. Release the pressure of the reactor to normal pressure, and react at a constant temperature of 140°C; then evacuate to -0.08MPa, and react at a constant temperature of 140°C, and finally pressurize the reactor to normal pressure and lower the temperature to 60°C, continue to stir and react at a constant temperature for 1h ;

[0051] 3. Cool the reactor to 23°C, stop stirring, and discharge the material to obtain the fluorine-containing polyamide. ...

preparation example 2

[0063] Preparation Example 2 Preparation of Modified Filler

[0064] S1. Add 100 parts of light calcium carbonate with an average particle size of 30 μm to a heating type high-speed mixer, raise the temperature to 100°C for preheating and drying, then cool down to 50°C, and keep the constant temperature at a speed of 500r / min. Under stirring conditions, add 0.5 parts of ammonia water with a concentration of 15%;

[0065] S2. Spray 3 parts of 3-(2,3-glycidoxypropyl)trimethoxysilane on the surface of the filler, increase the speed to 1300r / min and stir for 50min, then stop stirring and cool to room temperature to obtain the modified filler.

preparation example 3

[0067] The rest is the same as Preparation Example 2, except that the amount of 3-(2,3-glycidoxypropyl)trimethoxysilane is 1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com