Solid-state filling adhesive with heat conduction function, and preparation method thereof

A filling, solid-state technology, applied in the direction of adhesives, epoxy resins, adhesive types, etc., can solve the problem that solid-state fillers do not have thermal conductivity, and achieve good thermal conductivity, reduce agglomeration, and improve the effect of thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

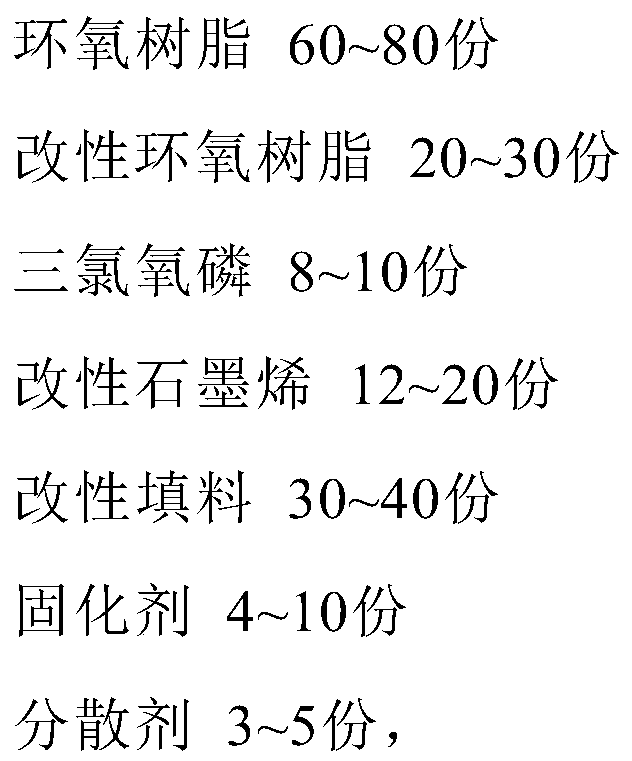

[0028] A solid filler with thermal conductivity, consisting of the following raw materials in parts by weight:

[0029]

[0030] Wherein, the modified graphene surface has oxygen-containing groups; the modified filler includes graphene with a particle size of 300nm, alumina and silicon powder with a particle size of 0.2 μm, and the mass ratio of graphene, aluminum oxide and silicon powder is 1:5:4; The surface of the modified epoxy resin is modified with nanostructured core-shell rubber particles.

[0031] The preparation method of the solid filler with heat conduction function comprises the following steps:

[0032] S1. Add graphene, alumina and silicon micropowder into ethanol solvent for reaction and dissolution according to the number of parts. The reaction temperature is 35-45° C., and the reaction time is 3-5 hours. After the reaction is completed, wash and dry to obtain a modified filler;

[0033] S2, take another graphene, ethanol, sodium hydroxide and cationic sur...

Embodiment 2

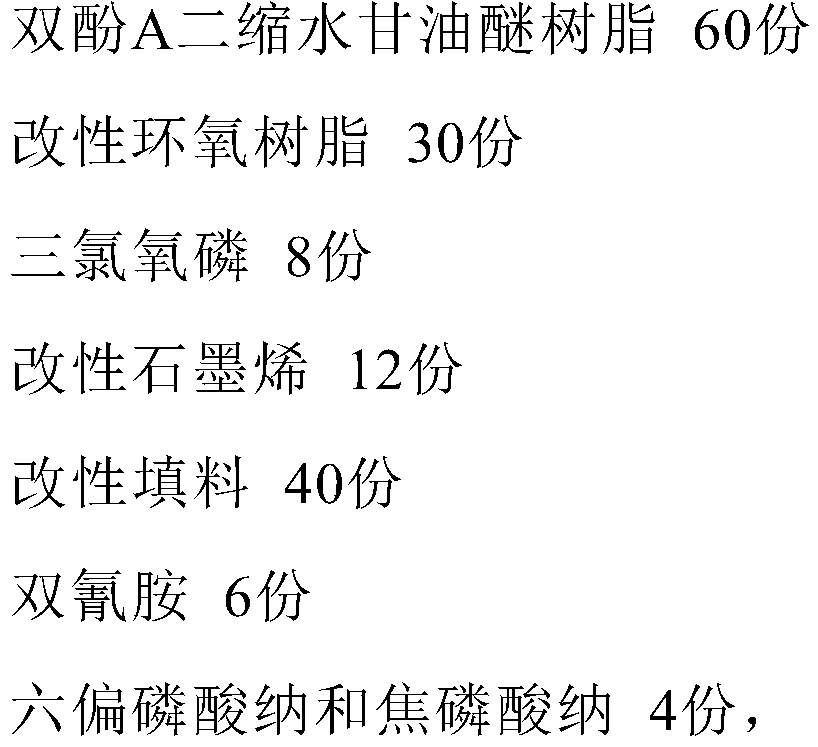

[0036] A solid filler with thermal conductivity, consisting of the following raw materials in parts by weight:

[0037]

[0038]

[0039] Wherein, the modified graphene surface has oxygen-containing groups; the modified filler includes graphene with a particle size of 400nm, alumina and silicon powder with a particle size of 0.5 μm, and the mass ratio of graphene, aluminum oxide and silicon powder is 2:5:3; The surface of the modified epoxy resin is modified with nanostructured core-shell rubber particles.

[0040] The preparation method of the solid filler with heat conduction function comprises the following steps:

[0041] S1. Add graphene, alumina and silicon micropowder into ethanol solvent for reaction and dissolution according to the number of parts. The reaction temperature is 35-45° C., and the reaction time is 3-5 hours. After the reaction is completed, wash and dry to obtain a modified filler;

[0042]S2, take another graphene, ethanol, sodium hydroxide and c...

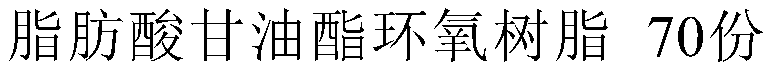

Embodiment 3

[0045] Different from Example 1, the bisphenol A diglycidyl ether resin in this example is 80 parts, and the modified epoxy resin is 20 parts.

[0046] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com