Naturally degradable nanofiber environment-friendly mask

A technology of nanofibers and masks, applied in the field of environmental protection masks, can solve the problems of large fluidity and dispersion, environmental pollution, environmental damage, etc., and achieve the effect of improving electrostatic holding capacity, improving capture efficiency, and improving holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

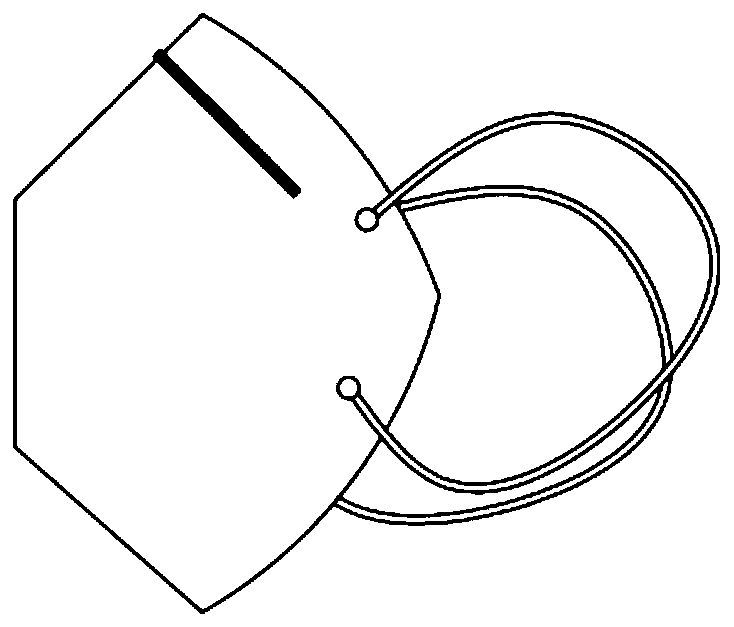

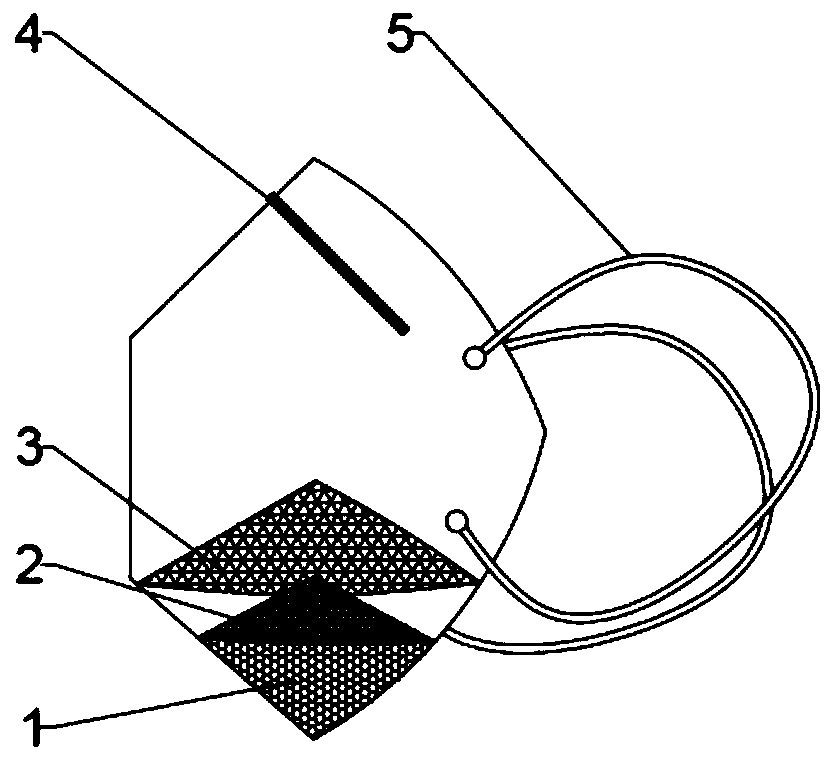

Image

Examples

Embodiment 1

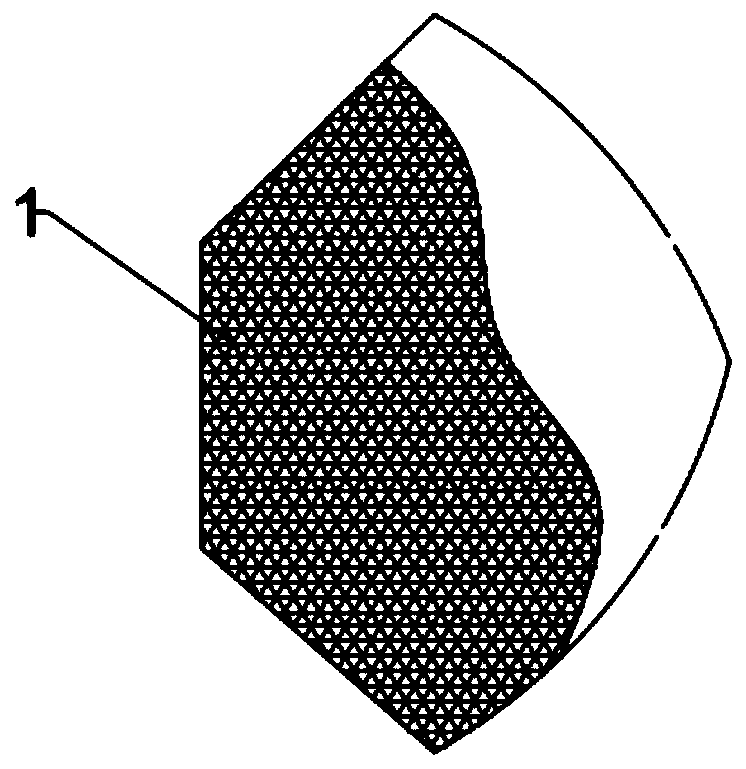

[0027] Polylactic acid is used as the main material of the mask, and the melt differential electrospinning technology is used to collect it by rollers to prepare a polylactic acid nanofiber orientation film with an average diameter of 300nm and an area density of 0.3g / m2 for use in masks. An inner filter layer 1 with a micro-nano gradient structure is fabricated. By adjusting the spinning voltage of melt differential electrospinning, changing the drafting force of the electric field, and collecting it by rollers, an oriented nanofiber film with an average diameter of 800nm and an area density of 3g / m2 was prepared for making Intermediate filter layer 2 with micro-nano gradient structure. The polylactic acid material and the silica powder with an average diameter of 10nm are blended at a ratio of 2%, and then the spinning voltage is further reduced to prepare thick fibers with an average diameter of 5-10 μm and an area density of 10g / m2. It is used to make the outer support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com