Parallel fiber reinforced silver graphite strip-shaped contact material and preparation method thereof

A technology of parallel fibers and contact materials, applied in the direction of welding/cutting media/materials, contacts, welding equipment, etc., can solve the problems of insignificant influence, low bonding strength, contact falling off, etc., and achieve high material utilization rate, Excellent processing performance, the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a) 14.55kg silver powder and 0.45kg graphite powder are mixed uniformly in the powder mixing equipment;

[0037] b) Melt 22.5kg of silver and 27.5kg of oxygen-free copper in a graphite crucible of an intermediate frequency melting furnace to form a silver-copper alloy melt, and use high-pressure water atomization equipment to prepare silver-copper alloy powder, which is dried and screened to form a weld layer powder;

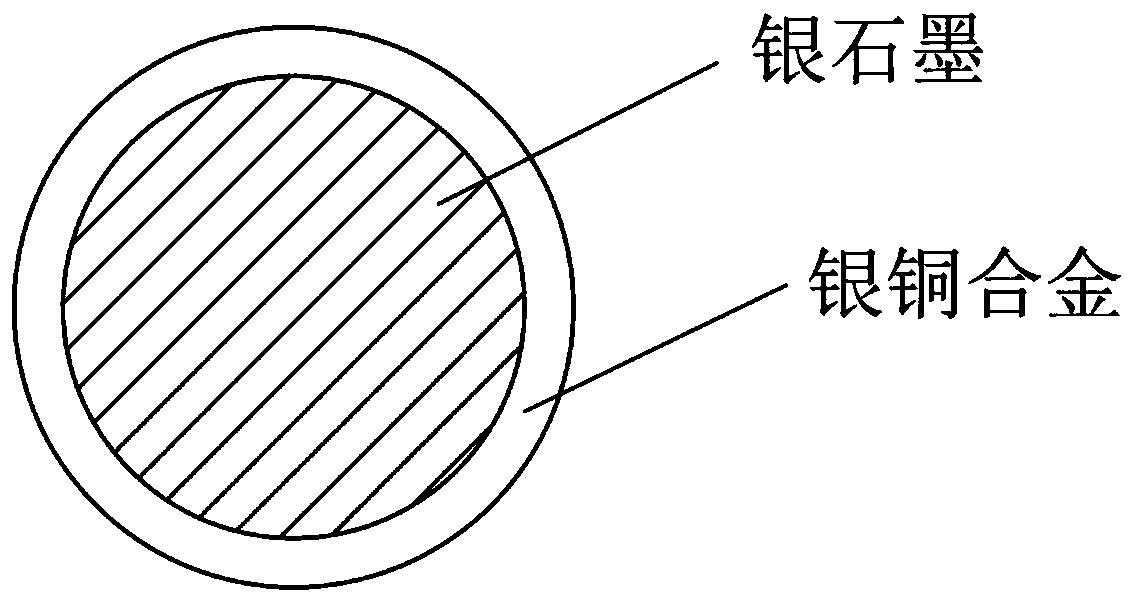

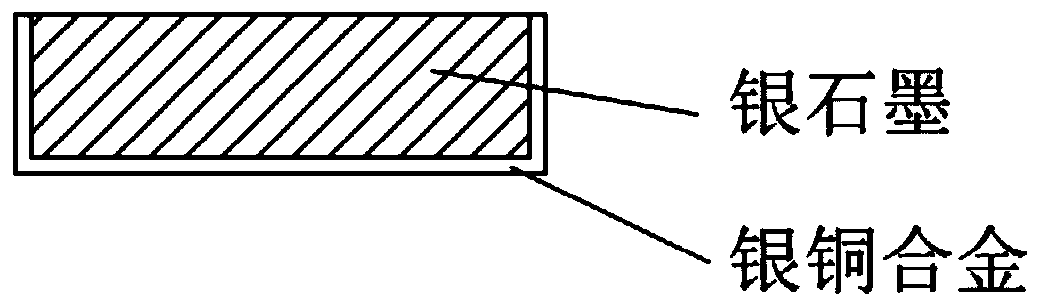

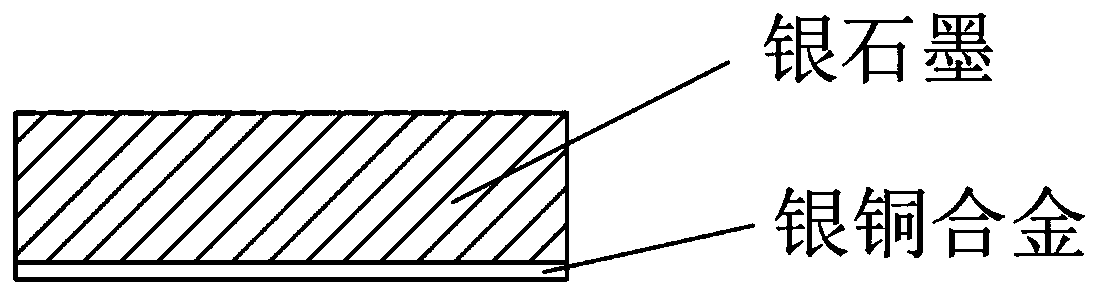

[0038] c) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. The center line of the rubber sleeve coincides with the center line of the metal partition. Put the silver graphite powder into the space of the metal partition, and the silver-copper alloy powder. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with silver graphite in the center and s...

Embodiment 2

[0044] a) 14.25kg silver powder and 0.75kg graphite powder are mixed uniformly in the powder mixing equipment;

[0045] b) Melt 30kg of silver and 20kg of oxygen-free copper in a graphite crucible of an intermediate frequency melting furnace to form a silver-copper alloy melt, and use high-pressure water atomization equipment to prepare silver-copper alloy powder, which is dried and sieved to form a welding layer powder ;

[0046] c) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. The center line of the rubber sleeve coincides with the center line of the metal partition. Put the silver graphite powder into the space of the metal partition, and the silver-copper alloy powder. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with silver graphite in the center and sil...

Embodiment 3

[0052] a) 14.4kg silver powder and 0.6kg graphite powder are mixed uniformly in the powder mixing equipment;

[0053] b) Melt 25kg of silver and 25kg of oxygen-free copper in the graphite crucible of the intermediate frequency melting furnace to form a silver-copper alloy melt, and use high-pressure water atomization equipment to prepare silver-copper alloy powder, which is dried and screened to form welding layer powder ;

[0054] c) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. The center line of the rubber sleeve coincides with the center line of the metal partition. Put the silver graphite powder into the space of the metal partition, and the silver-copper alloy powder. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with silver graphite in the center and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com