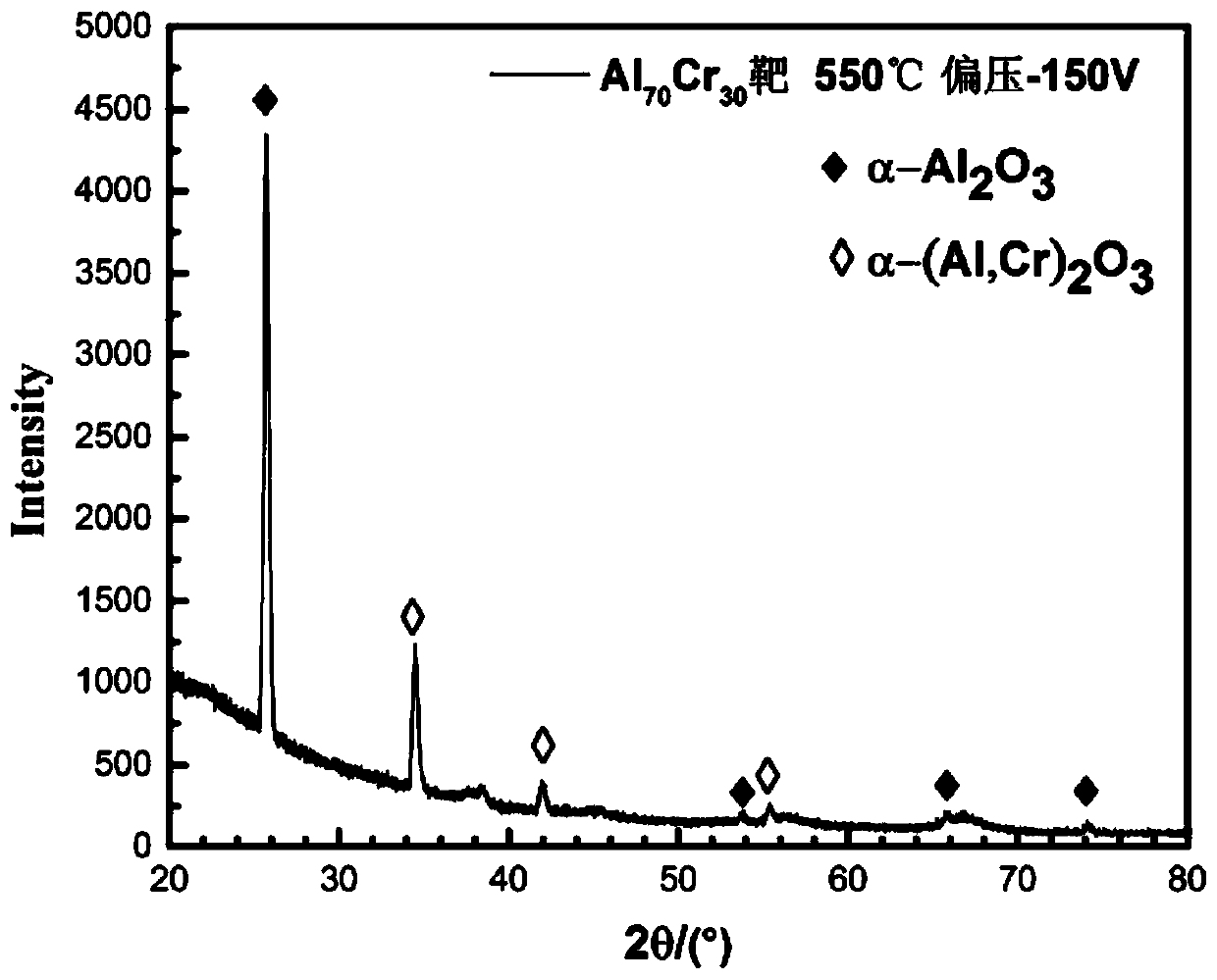

Al-rich corundum structure Al-Cr-O thin film and preparation method thereof

A technology of al-cr-o and corundum, which is applied in the field of Al-rich corundum structure Al-Cr-O film and its preparation, can solve the problem of reducing stability and reliability, difficult practical application, and reducing corundum structure Al-Cr-O Deposition temperature and other issues, to achieve the effect of small friction coefficient and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

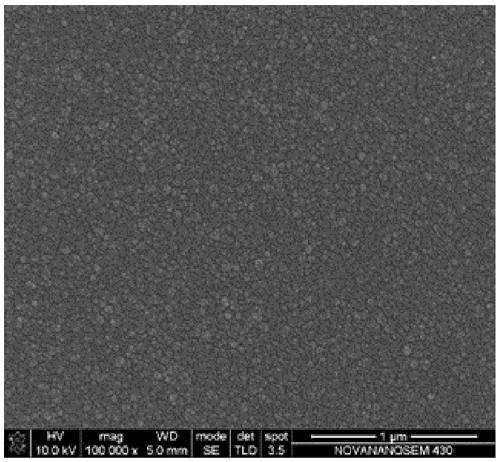

Embodiment 1

[0027] Deposition of Al-corundum Al-Cr-O Thin Films on W9Mo3Cr4V High Speed Steel

[0028] (1) Customized Φ60*3mm Al 70 Cr 30 and pure Cr target, installed on the corresponding target station, adjust the target base distance to 80mm.

[0029] (2) Cut the W9Mo3Cr4V high-speed steel quenched + 560°C and tempered three times into Φ15×5mm size, polished to a mirror surface, ultrasonically cleaned in acetone and absolute ethanol for 15min, dried and placed on the sample stage.

[0030] (3) Pre-evacuate to 10Pa, turn on the infrared baking system and heat to 150°C, and then evacuate to 5×10 -4 Pa, turn off the bake, heat the substrate to 550°C, and continue vacuuming to 5×10 -4 Pa.

[0031] (4) Introduce Ar gas, adjust the air pressure to 1.0Pa, maintain the temperature at 550°C, use a DC power supply to sputter a pure Cr target, and the target power density is 5.3W / cm 2 , the sputtering time is 20min, and a Cr transition layer of 0.5-0.6um is obtained.

[0032] (5) Turn the...

Embodiment 2

[0037] Deposition of Al-corundum Al-Cr-O Thin Films on W9Mo3Cr4V High Speed Steel

[0038] (1) Customized Φ60*3mm Al 70 Cr 30 and pure Cr target, installed on the corresponding target station, adjust the target base distance to 80mm.

[0039] (2) Cut the W9Mo3Cr4V high-speed steel quenched + 560°C and tempered three times into Φ15×5mm size, polished to a mirror surface, ultrasonically cleaned in acetone and absolute ethanol for 15min, dried and placed on the sample stage.

[0040] (3) Pre-evacuate to 10Pa, turn on the infrared baking system and heat to 150°C, and then evacuate to 5×10 -4 Pa, turn off the bake, heat the substrate to 550°C, and continue vacuuming to 5×10 -4 Pa.

[0041] (4) Introduce the Ar body, adjust the air pressure to 1.0Pa, maintain the temperature at 550°C, use a DC power supply to sputter a pure Cr target, and the target power density is 5.3W / cm 2 , the sputtering time is 20min, and a Cr transition layer of 0.5-0.6um is obtained.

[0042] (5) Tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com