Method for drying a substrate, dryer module for carrying out the method, and dryer system

A technology for dryers and substrates, applied in progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems of complex structure of hole and slot nozzles, and achieve fast and efficient drying, high-efficiency drying, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

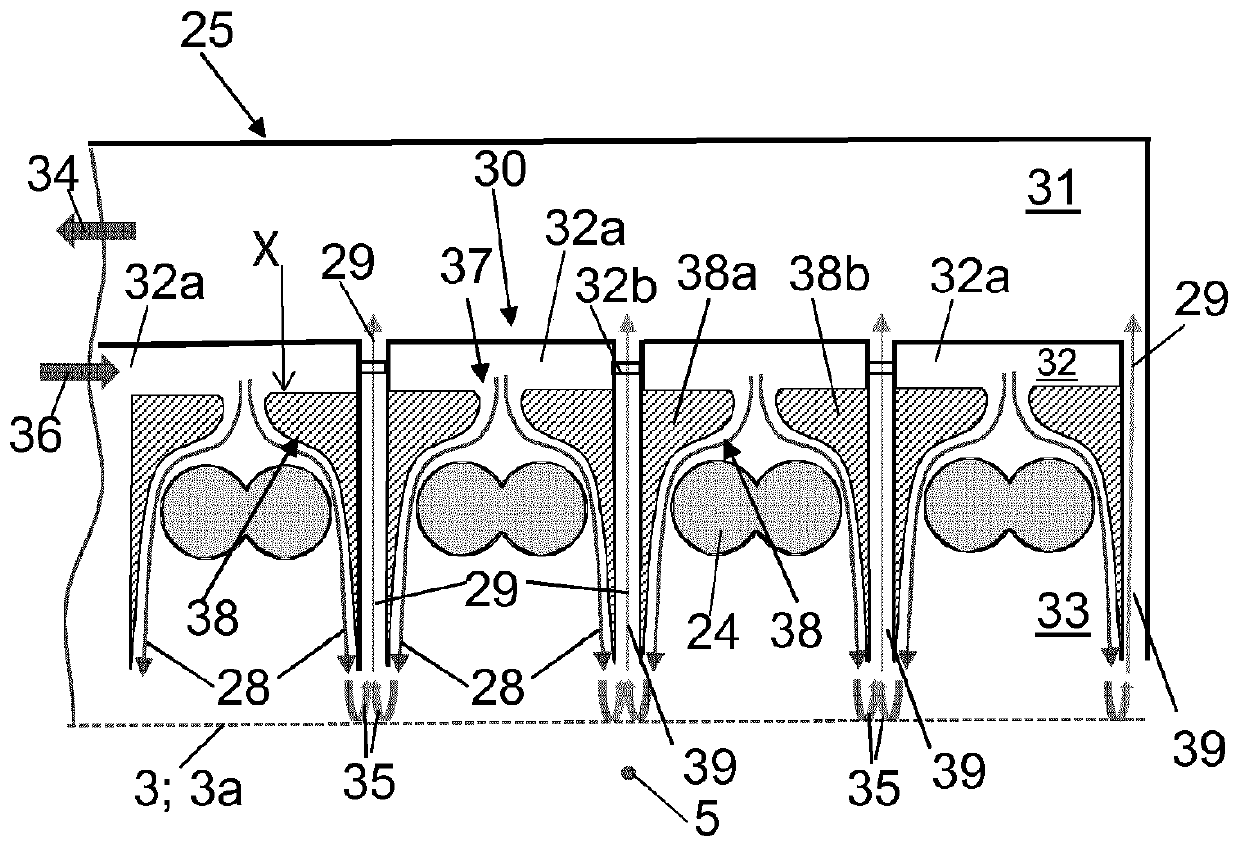

[0093] In infrared emitters, a heating wire made of carbon or tungsten in the form of a coil or strip is enclosed in an emitter tube filled with an inert gas, usually made of quartz glass. The heating wire is linked to an electrical connection which is introduced via one or both ends of the emitter tube.

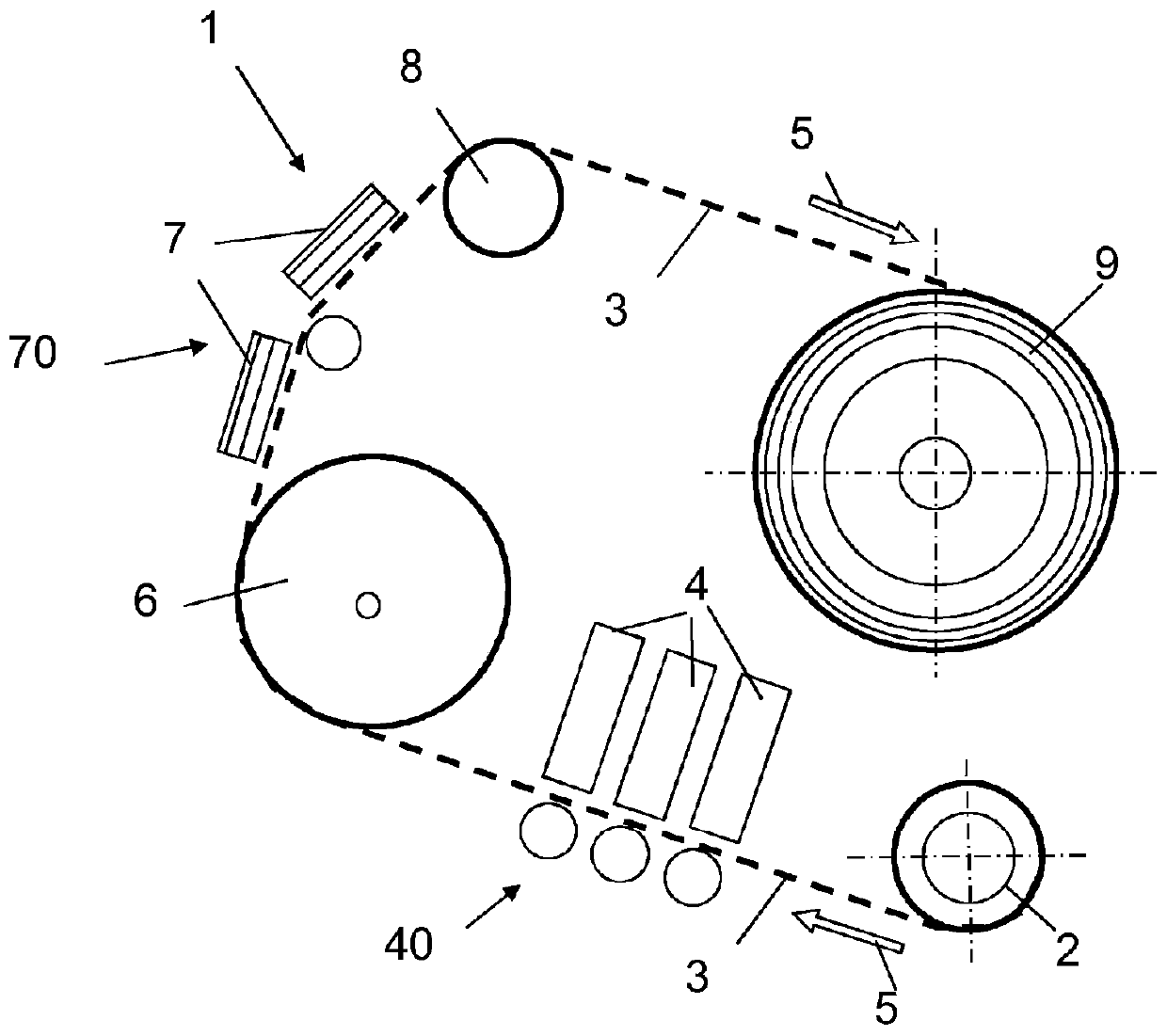

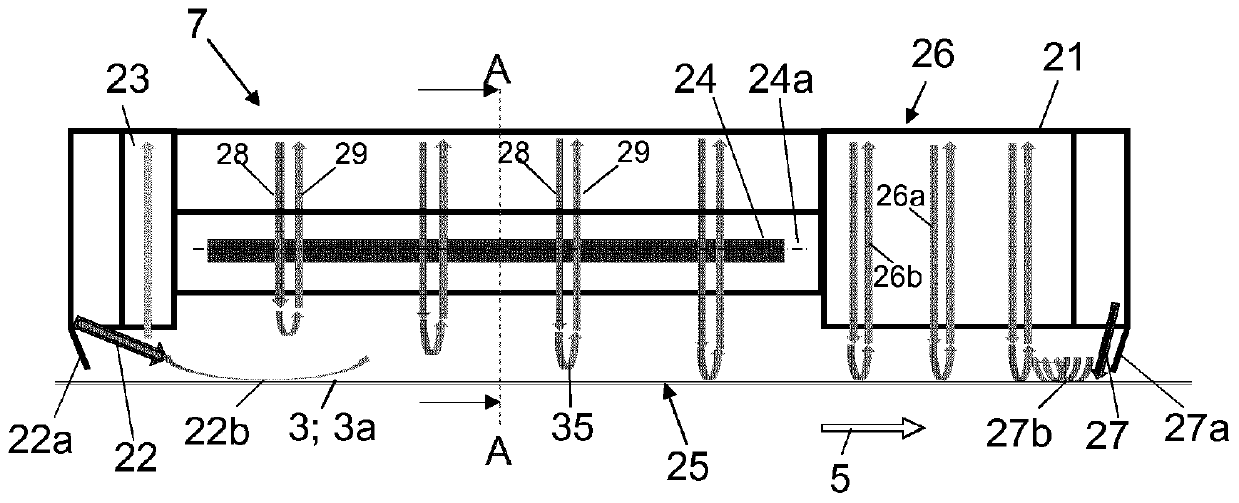

[0094] figure 1 A schematic view of a printing press in the form of a roll-feed inkjet printing press is shown, which is generally designated by the reference number 1 . From the unwinder 2 a material web 3 consisting of a printing substrate such as paper travels from the unwinder 2 to a printing unit 40 . The printing unit comprises a plurality of inkjet printing heads 4 arranged one behind the other along the material web 3 , by means of which solvent-based, in particular aqueous, printing inks are applied to the printing substrate.

[0095] The material web 3 then travels from the printing unit 40 via the deflection roller 6 to the infrared dryer system 70 when viewed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com