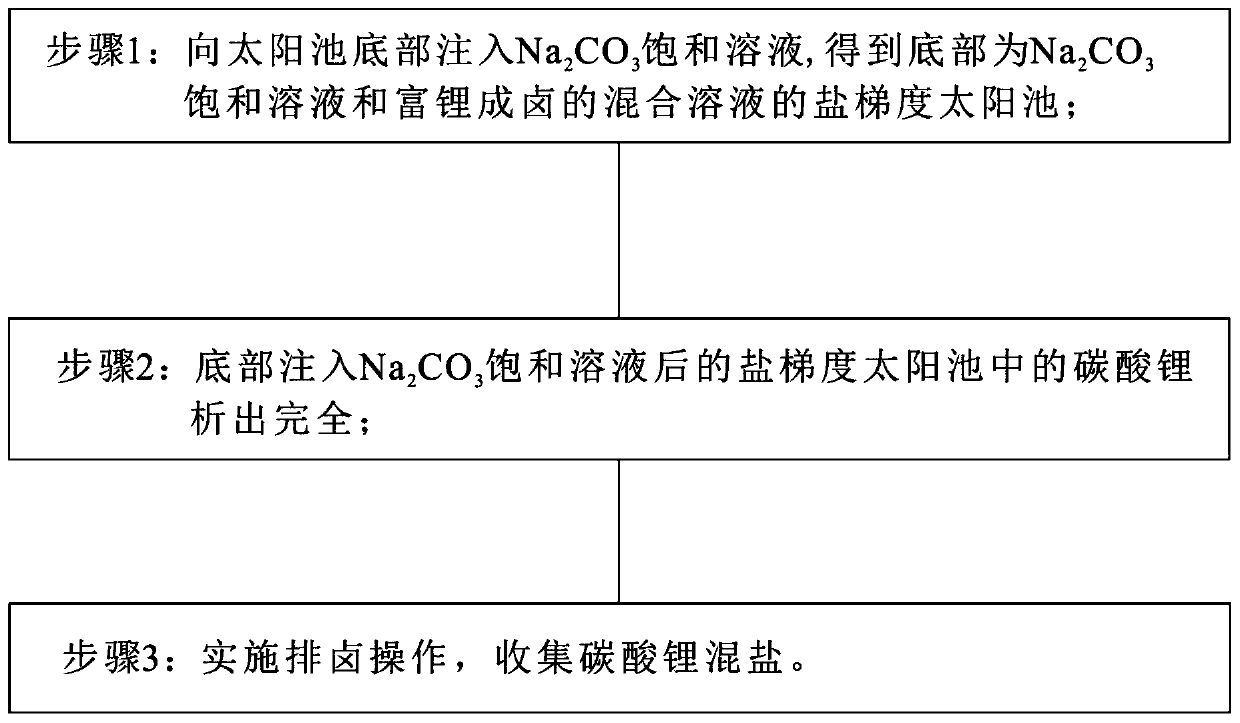

Solar pond lithium extraction method

A solar pool and lithium-rich technology, which is applied in the field of lithium extraction from solar pools, can solve the problems of low lithium yield and achieve the effects of improving crystallization efficiency, wide application prospects, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The A1 solar pool of a workshop in the Zabuye mining area of Tibet was selected to carry out the disturbance experiment (no sodium carbonate was added, only disturbance). The bottom area of A1 solar pool is 2500m 2 , the brine filling depth is 2m, and two submersible pumps are placed diagonally at a distance of 50cm from the bottom of the A1 solar pool. The power of the submersible pump is 3kw, and the flow control of the submersible pump is 50m 3 / h. The temperature rise of the concentrated lithium-rich brine in the A1 solar pool is basically stable, and the first mechanical disturbance begins when the temperature of the brine reaches 40°C. The first cycle lasts a total of 64 hours. A second mechanical disturbance was performed after an interval of two months, and the second cycle lasted a total of 50 hours. Before and after the first and second disturbances, longitudinal observation and sampling of the A1 solar pool and brine Li + The test analysis of concentra...

Embodiment 2

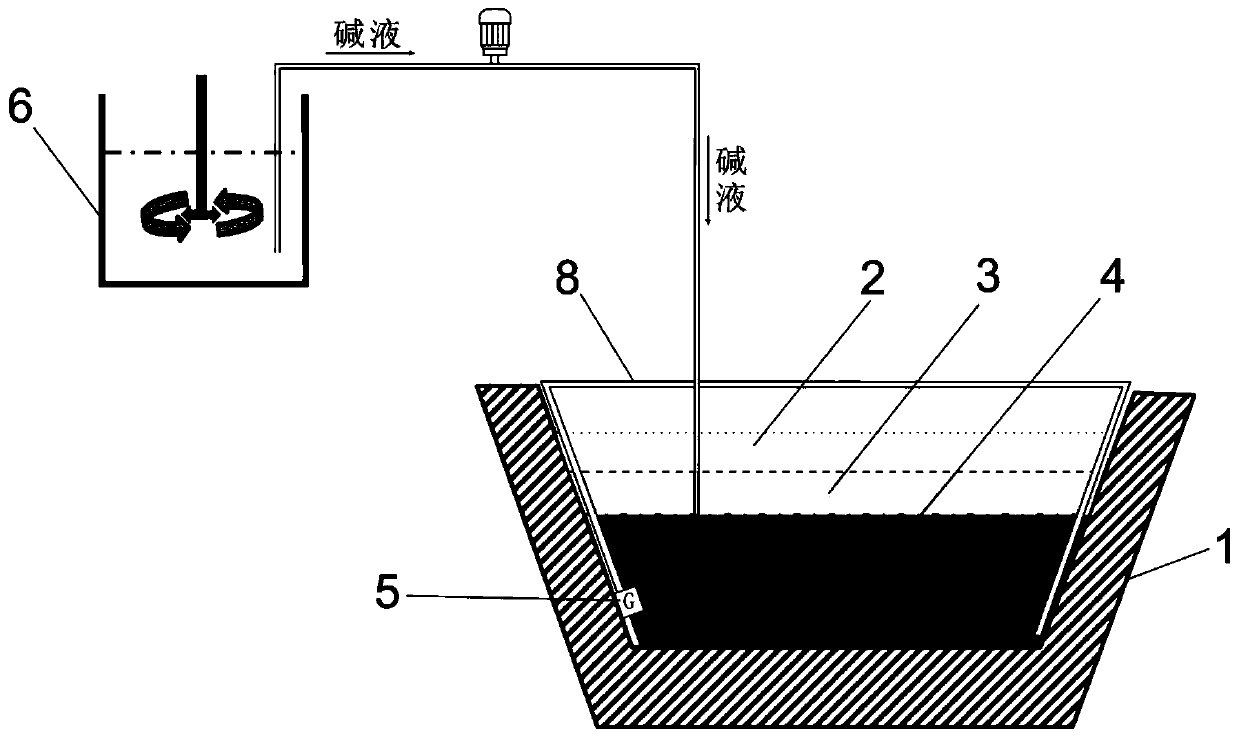

[0088] The B1 solar pond of a workshop in the Zhabuye mining area of Tibet was selected, and the lithium extraction method of the solar pond of the present invention was used to carry out experiments on the B1 solar pond by increasing the temperature of the traditional solar pond and supplementing the carbonate precipitation method. Among them, the original halogen Li + The concentration is 2.03g / L, CO 3 2- The concentration is 19.46g / L, which is a typical high Li + low CO 3 2- into brine. The bottom area of B1 solar pool is 2500m 2 , the depth of brine filling is 2m, and then a layer of fresh water with a thickness of 1m is laid on the surface, and it is left to stand for several days until the salt gradient solar pool is completely formed and enters the stage of stable temperature rise and lithium analysis. Alkali operation. The method of adding alkali adopts the first method, adding 105 tons of alkali in total, and injecting the lye into the solar pool through th...

Embodiment 3

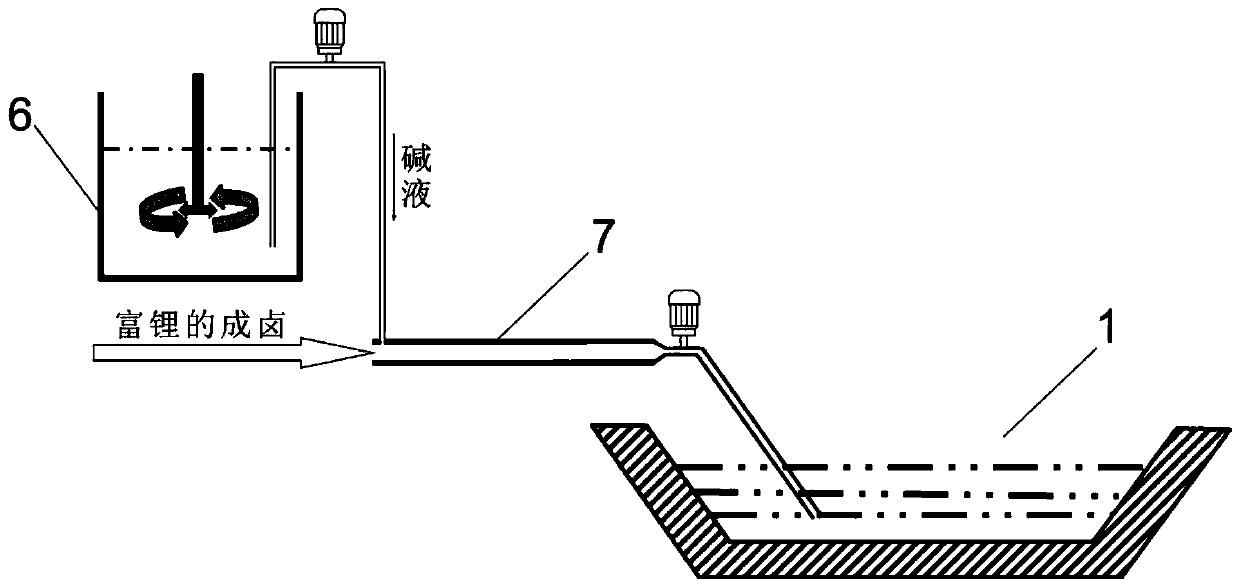

[0093] The B2 solar pond of a workshop in the Zhabuye mining area of Tibet was selected, and the method for extracting lithium from the solar pond of the present invention was used to carry out experiments on the B2 solar pond by increasing the temperature of the traditional solar pond and supplementing the carbonate precipitation method. Among them, the original halogen Li + The concentration is 2.02g / L, CO 3 2- The concentration is 27.73g / L, which belongs to high Li + low CO 3 2- into brine. The bottom area of B2 solar pool is 2500m 2 . The method of adding alkali adopts the second method, a total of 108.45 tons of alkali is added, and the alkali solution and brine are mixed in the brine channel and then poured into the solar pond together. The prepared Na 2 CO 3 The saturated solution is injected into the brine delivery channel, mixed with the formed brine in the brine delivery channel, and then a water pump is used. The power of the submersible pump is 3kw, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com