Refuse landfill leachate treatment method and system

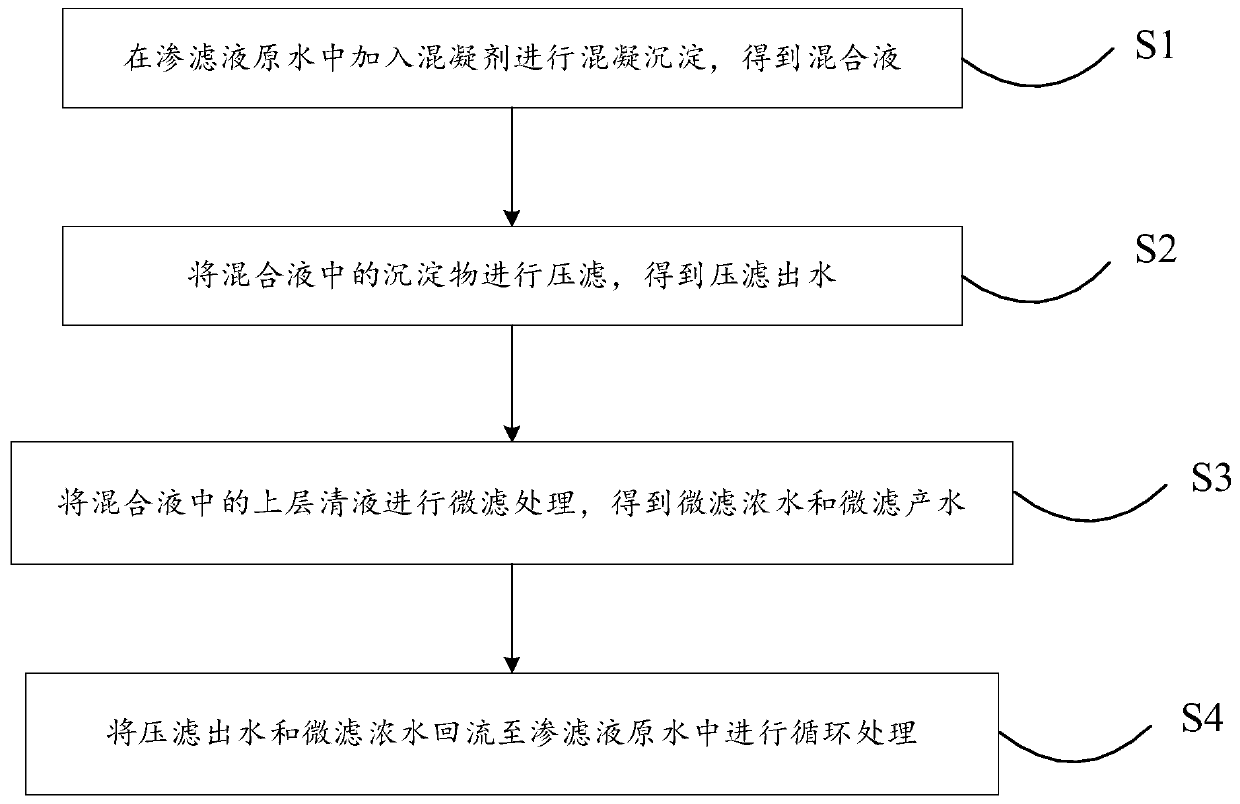

A technology for a landfill and a treatment method, which is applied in the field of leachate treatment in landfills, and can solve problems such as membrane pollution, blockage of flow channels, and sulfur pollution of sulfide membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

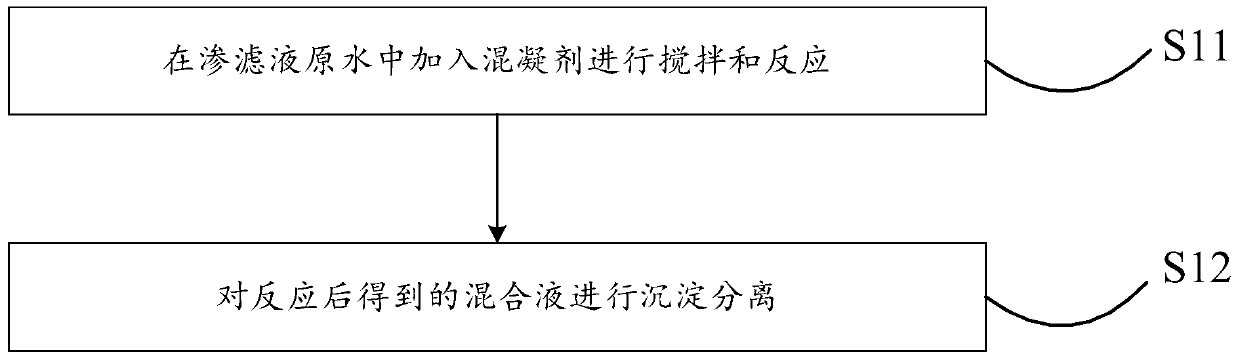

Method used

Image

Examples

Embodiment 1

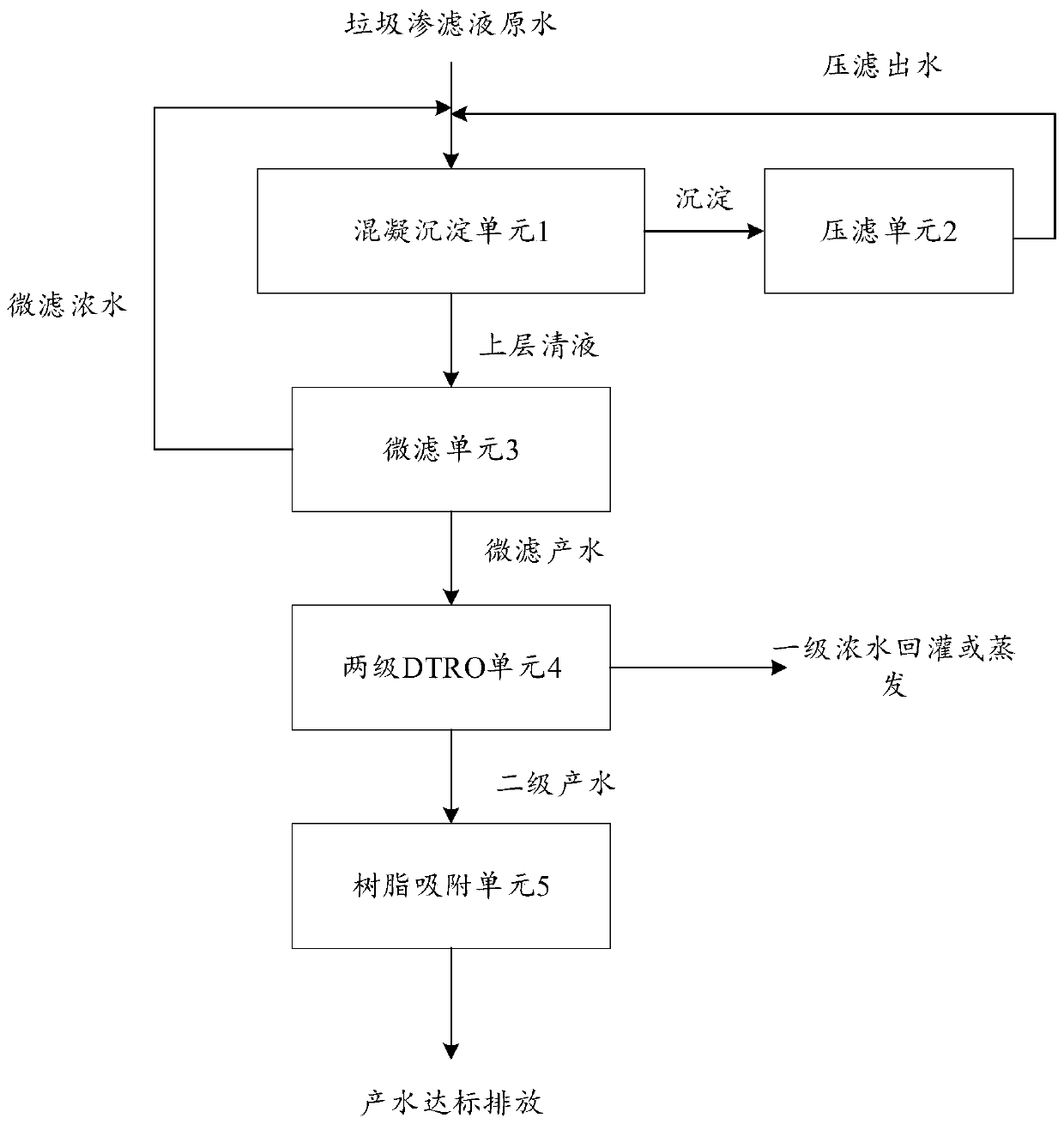

[0053] The leachate raw water treated at a landfill in Henan, the original membrane process is "leachate raw water + basket filter + sand filter + core filter + two-stage DTRO + resin adsorption", due to the leachate raw water suspended matter content High, the sand filter is often backwashed, and the flow channel of the DTRO membrane is often blocked. Then adopt the process of "modified pretreatment + microfiltration (submerged MBR) + two-stage DTRO + resin adsorption". Type MBR unit, the water produced by microfiltration is sucked by a self-priming pump, the operating pressure is 20-50kpa, the bottom uses microporous aeration, and the aeration intensity is 100Nm 3 / h·m 2 , the microfiltration concentrated water reflux ratio is 50%, and the microfiltration product water enters the two-stage DTRO. Then the ammonia nitrogen is removed by resin adsorption and discharged up to the standard. The water quality of each stage is as follows:

[0054]

[0055]

Embodiment 2

[0057] The leachate raw water treated by a landfill in Shanxi, the original membrane process is "leachate raw water + basket filter + sand filter + core filter + two-stage DTRO + resin adsorption", because the leachate raw water has high suspended matter , sand washing is frequent, and the concentration of sulfide in the leachate raw water is high, and there is sulfur pollution in the DTRO membrane column. Then adopt the process of "modified pretreatment + microfiltration (submerged MBR) + two-stage DTRO + resin adsorption". Type MBR unit, the produced water is sucked by a self-priming pump, the operating pressure is 20-50kpa, the bottom uses microporous aeration, and the aeration intensity is 100Nm 3 / h·m 2 , the reflux ratio of the microfiltration concentrated water is 50%; the microfiltration product water enters the two-stage DTRO, the operating pressure of the first-stage DTRO is 50-75bar, the operating pressure of the second-stage DTRO is 20-30bar, and the two-stage DTR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com