Synthesis method of modified acrylic acid-acrylamide copolymer builder

A technology of acrylamide copolymerization and acrylic acid copolymer, which is applied in detergent compounding agents, chemical instruments and methods, detergent compositions, etc., can solve problems such as expensive initiators, toxic and harmful solvents, and influence on builder performance, and achieve Reduce the cost of traditional production, reduce the harm of environmental pollution, and have excellent washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

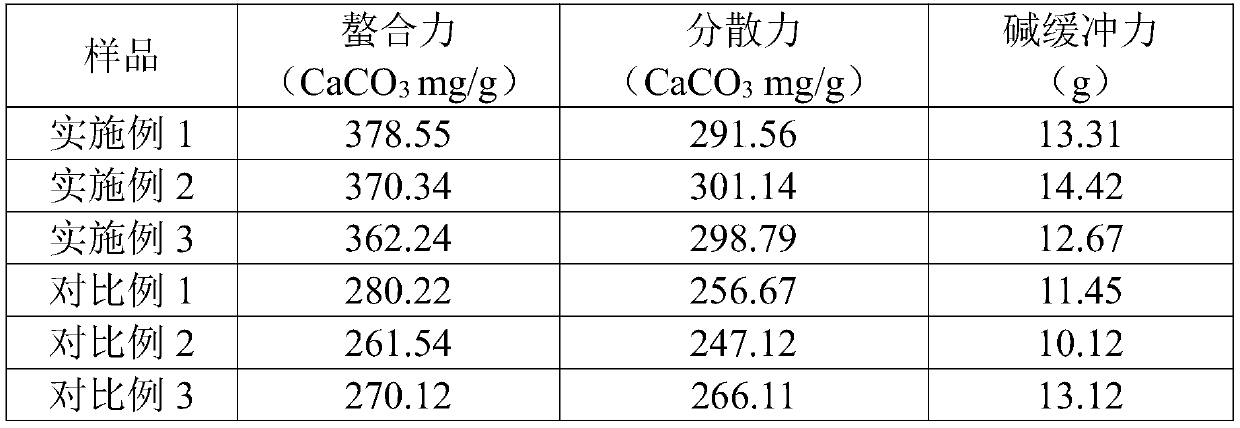

Examples

Embodiment 1

[0024] First add 2kg of deionized water to the reactor, pass nitrogen, and when the temperature is raised to 70°C while stirring, simultaneously add dropwise 126kg of acrylic acid, 185kg of acrylamide 40% aqueous solution, 4kg of initiator potassium persulfate solution, and 4kg of sodium bisulfite solution. The reaction time is 2 hours; then take 10kg of copolymer, add 13kg of formaldehyde solution, 8kg of dimethylamine solution and 2kg of hydrochloric acid solution, and react for 3 hours at 70 degrees to obtain the modified polymer.

Embodiment 2

[0026] First add 2kg of deionized water to the reactor, pass nitrogen, and when the temperature is raised to 70°C while stirring, simultaneously add 126kg of acrylic acid, 185kg of acrylamide 40% aqueous solution, 4kg of initiator sodium persulfate solution, and 4kg of potassium bisulfite solution. The reaction time is 2.5 hours; take 10kg of copolymer, add 13kg of formaldehyde solution, 8kg of dimethylamine solution and 2kg of hydrochloric acid solution, and react for 3 hours at 70 degrees to obtain the modified polymer.

Embodiment 3

[0028] First add 2kg of deionized water to the reactor, pass nitrogen gas, and when the temperature rises to 80°C while stirring, add 126kg of acrylic acid, 185kg of acrylamide 40% aqueous solution, 4kg of initiator sodium persulfate solution, and 4kg of sodium metabisulfite solution dropwise at the same time. Take 10kg of copolymer, add 13kg of formaldehyde solution, 8kg of dimethylamine solution and 2kg of hydrochloric acid solution, and react for 3 hours at 65 degrees to obtain the modified polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com