Phosphorus-nitrogen flame retardant, preparation method thereof and polypropylene composite material containing the phosphorus-nitrogen flame retardant

A phosphorus-nitrogen flame retardant and composite material technology, which is applied in the field of polypropylene composite materials, can solve problems such as increased environmental pollution, decreased material properties, and increased costs, achieving high reaction efficiency, improved flame retardant performance, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

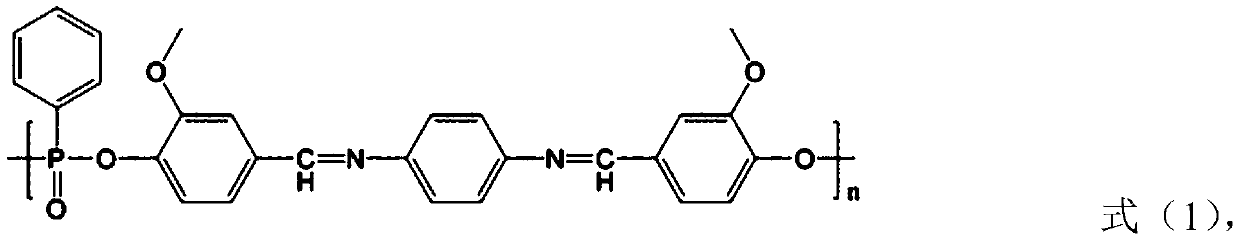

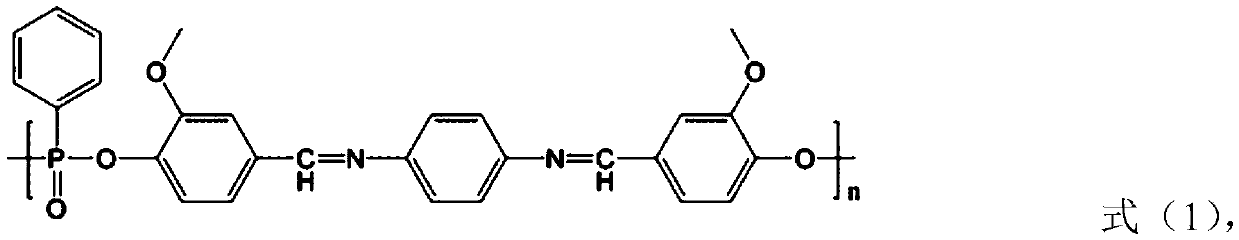

[0042] The phosphorus-nitrogen flame retardant of the present embodiment is prepared by the following steps:

[0043] S1. Dissolve 0.04mol vanillin in chloroform to obtain a reaction solution, add it to a three-necked flask, then feed nitrogen and heat up, turn on the magnetic stirrer and stir at 300r / min;

[0044] S2. Dissolve 0.02mol phenylphosphoryl dichloride in chloroform, slowly add it dropwise to the above reaction solution, heat up to 60°C and continue to react for 4 hours;

[0045] S3. 0.06mol triethylamine was dissolved in chloroform, slowly added dropwise to the above reaction solution, and the temperature was raised to 70° C. for 3 hours;

[0046] S4. Dissolve 0.02mol of p-phenylenediamine in chloroform, slowly add it dropwise to the above reaction solution, continue to react for 4 hours, cool to room temperature, wash, dry and grind to obtain a powdery phosphorus nitrogen flame retardant.

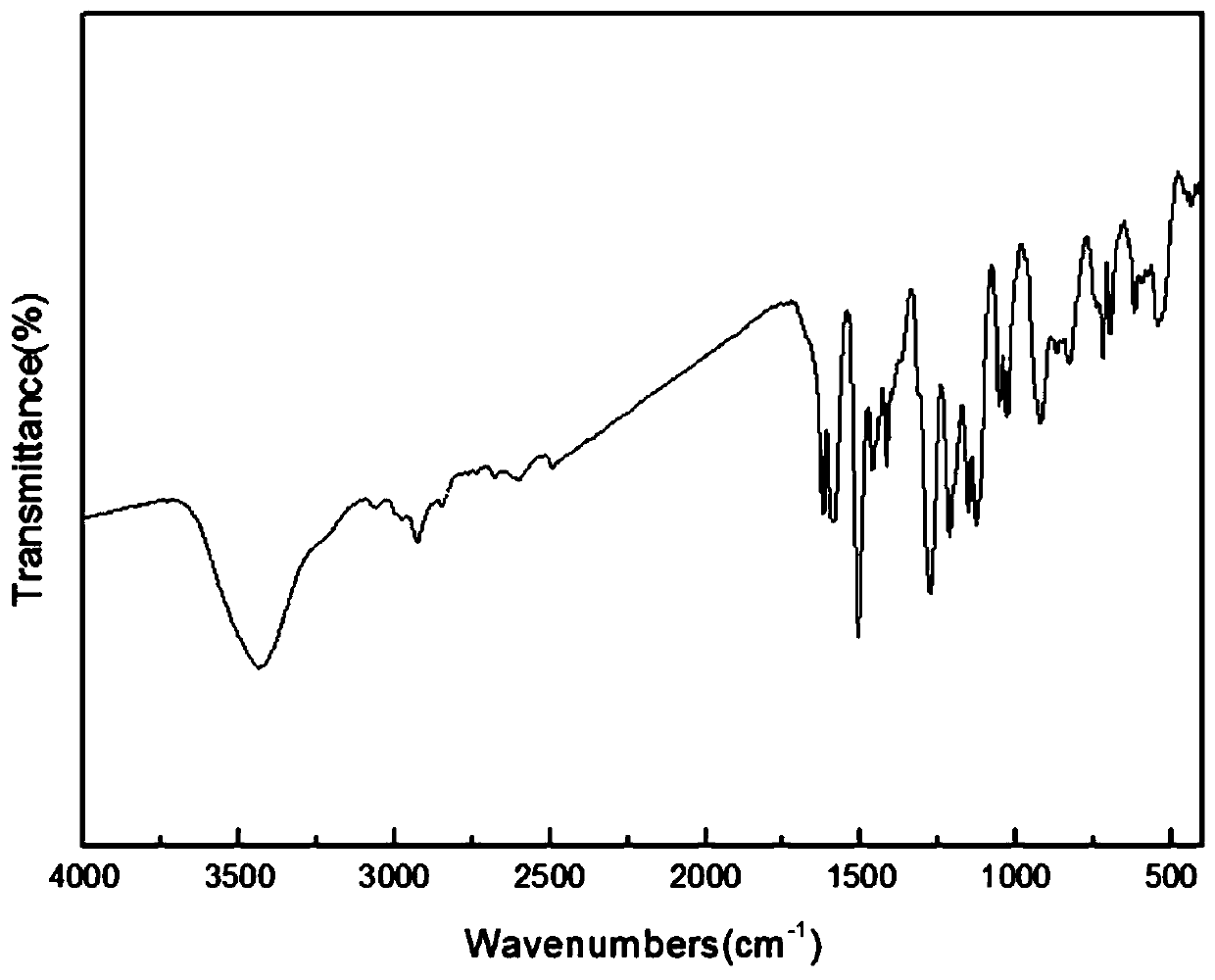

[0047] The infrared spectrogram of the phosphorus-nitrogen flame retardan...

Embodiment 2

[0049] The phosphorus-nitrogen flame retardant of the present embodiment is prepared by the following steps:

[0050] S1. Dissolve 0.045mol vanillin in dichloromethane to obtain a reaction solution, add it to a three-necked flask, then feed nitrogen and heat up, turn on the magnetic stirrer and stir at 400r / min;

[0051] S2. Dissolve 0.02mol phenylphosphoryl dichloride in methylene chloride, slowly add it dropwise to the above reaction solution, heat up to 65°C and continue to react for 3.5 hours;

[0052] S3. Dissolve 0.07mol triethylamine in dichloromethane, slowly add it dropwise to the above reaction solution, raise the temperature to 75°C and react for 2.5 hours;

[0053] S4. Dissolve 0.025mol p-phenylenediamine in dichloromethane, slowly add it dropwise into the above reaction solution, continue to react for 4.5 hours, cool to room temperature, wash, dry and grind to obtain powdered phosphorus nitrogen flame retardant.

Embodiment 3

[0055] The polypropylene composite material of the present embodiment comprises following composition:

[0056] Copolymerized polypropylene: 93.5 parts

[0057] The phosphorus-nitrogen flame retardant prepared in embodiment 1: 5 parts

[0058] Decabromodiphenyl ether: 1 part

[0059] Bruggemann H161 antioxidant: 0.3 parts

[0060] Zhonglan Chenguang DS101HC silicone powder: 0.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com