Gas quenching method for improving stability of steel slag and recycling physical heat of molten steel slag

A technology of steel slag physics and stability, which is applied in the field of gas quenching to improve the stability of steel slag while recovering the physical heat of molten steel slag. It can solve problems such as long reaction time, achieve low power consumption in the process, avoid secondary oxidation, and increase the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

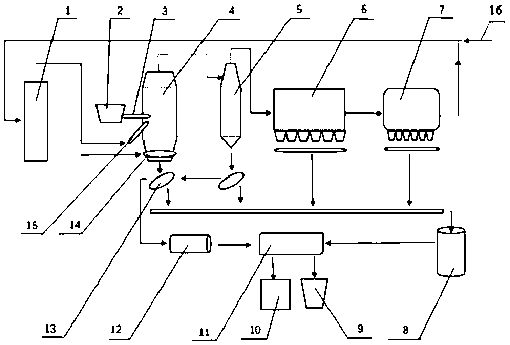

[0022] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0023] Refer to attached figure 1 , a gas quenching method for improving the stability of steel slag while recovering the physical heat of molten steel slag, which is operated according to the following steps:

[0024] Step I, transporting the molten steel slag from the slag tank used in the converter steelmaking system to the liquid steel slag ladle 2;

[0025] Step II, the molten steel slag in the liquid steel slag bag 2 flows to the gas quenching chamber 4 through the steel slag chute 3, and the CO 2 Enter the gas quenching chamber 4 from the high-pressure storage tank through the pipeline for gas quenching, the gas quenching pressure is 0.35MPa, and the gas-liquid mass ratio is 1:10; the molten steel slag is cooled rapidly, and most of the molten steel slag is quenched into particles below 3mm , molten steel slag and cold CO 2 heat exchange, while the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com