Cooling liquid and application thereof in cooling system of electronic equipment

A technology of electronic equipment and cooling system, applied in the direction of electrical digital data processing, instruments, digital data processing components, etc., can solve the problems of poor compatibility and compatibility, limited application scenarios and conditions, etc., and achieve good material compatibility , Improve the cooling efficiency and stabilize the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

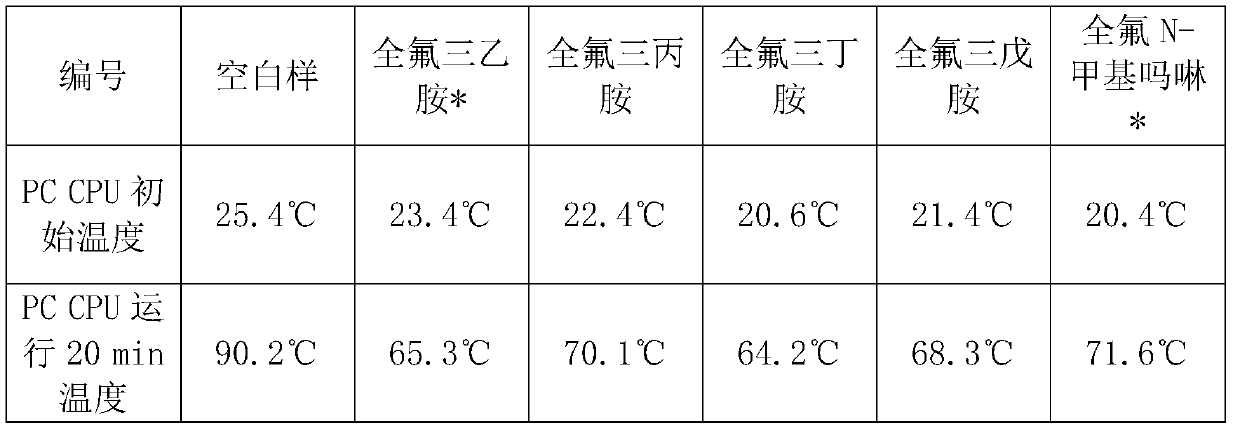

Image

Examples

Embodiment 1

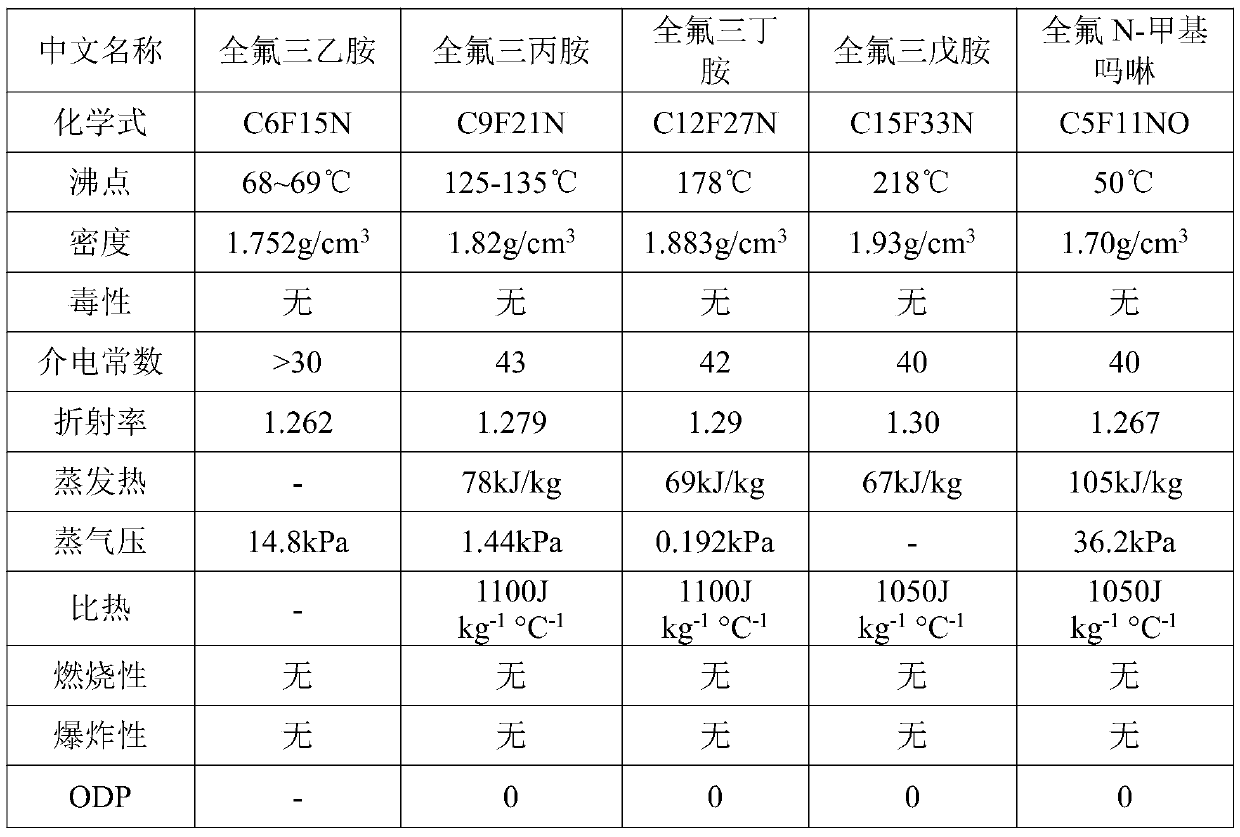

[0032] Check the airtightness of the host computer of an ordinary desktop PC, directly add perfluoroamine cooling liquid, and let all the accessories of the computer host be submerged in perfluoroamine for cooling. At the same time, the cold and heat exchange tubes are installed, and the cold and heat exchange tubes are immersed in the perfluoroamine cooling liquid, and tap water is passed through the cold and heat exchange tubes to cool down. Start the program and run the program continuously for one month, and observe the CPU temperature changes. The experimental test results when using different perfluoroamine coolants are shown in Table 2. Wherein, the blank sample in Table 2 refers to: the host computer of the desktop PC uses its own fan to rotate for cooling.

[0033] Table 2 Experimental test results

[0034]

[0035]It can be seen from the results in Table 2 that after a month of continuous operation of the mainframe of the desktop PC, the temperature of the CPU s...

Embodiment 2

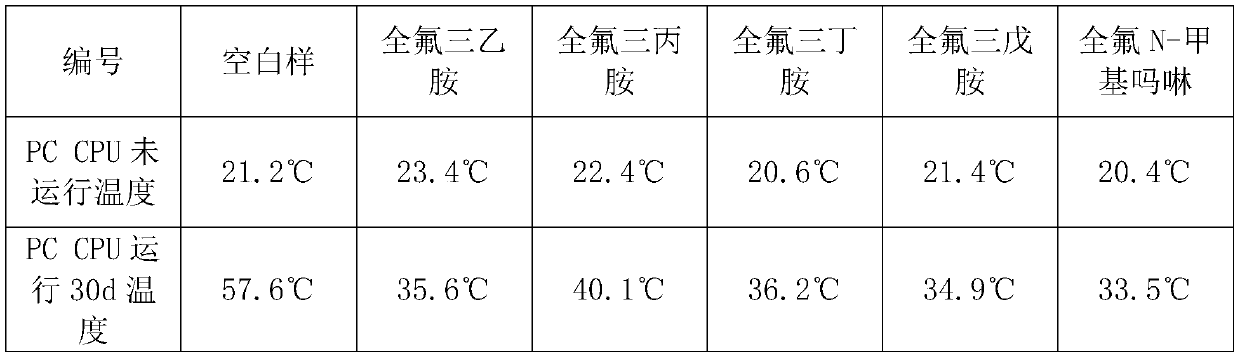

[0037] Check the airtightness of the host computer of an ordinary desktop PC, directly add perfluoroamine cooling liquid, and let all the accessories of the computer host be submerged in perfluoroamine for cooling. At the same time, the cold and heat exchange tubes are installed, and the cold and heat exchange tubes are immersed in the perfluoroamine cooling liquid, and tap water is passed through the cold and heat exchange tubes to cool down. Run the roaster software program continuously, observe the temperature indication, and the test results are shown in Table 3. Wherein the blank sample in Table 3 refers to: the host computer of the desktop PC is cooled by its own fan rotation.

[0038] Table 3 Test results of baking machine experiment

[0039]

[0040] In Table 3: * means that two-phase cooling is used for cooling, and the rest of the coolant test groups are cooled by single-phase cooling.

[0041] From the results in Table 3, it can be seen that the temperature of ...

Embodiment 3

[0043] The battery of the new energy vehicle is taken out, and different perfluoroamine cooling liquids are placed in the liquid cooling tube and indirectly contact the battery of the new energy vehicle through the liquid cooling tube. The cooling end of the liquid cooling tube is cooled with tap water. Install a temperature indicator on the battery, and test the temperature change of the battery under cooling with different fluorinated liquids. The test results are shown in Table 4. The blank sample in Table 4 refers to that the battery of the new energy vehicle is cooled by contacting the ambient air.

[0044] Table 4 Experimental test results

[0045]

[0046] Through comparison in Table 4, it is found that the immersion cooling fluid can protect the battery from overheating during operation and keep it at a safe temperature, so that the battery can operate more safely and efficiently.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com