Efficient composite sound insulation board

A sound insulation board and high-efficiency technology, applied in the direction of transformer/inductor noise damping, etc., to achieve the effect of optimizing sound insulation effect, weather-resistant construction, and increasing material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

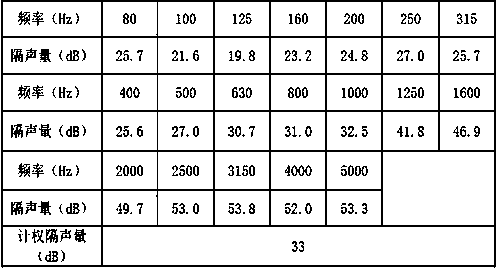

Embodiment 1

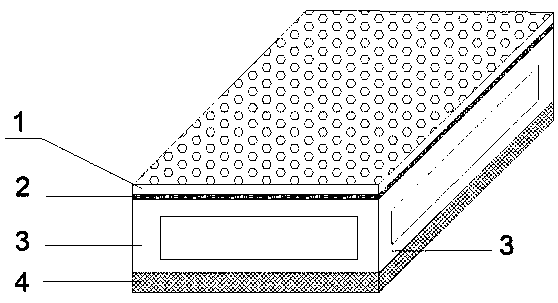

[0025] A high-efficiency composite sound insulation board, the sound insulation board adopts a sandwich composite structure, including double-layer high-density FRP, and the middle of the double-layer high-density FRP is filled with aluminum fiber felt. Density FRP and inner high-density FRP.

[0026] The high-density FRP is made of the following raw materials in parts by weight: 80 parts of unsaturated polyester resin, 30 parts of alkali-free glass fiber, 5 parts of cyclohexanone peroxide, 10 parts of tert-butyl peroxybenzoate, phthalic acid 2 parts of dipropylene fat, 50 parts of iron powder, 0.5 part of organosiloxane, the density of the high-density fiberglass is 1.4-2.1g / cm 3 .

[0027] The thickness of high-density FRP on the inner side (that is, the side facing the sound source) is 1 mm, and microholes with a diameter of 0.5 mm are opened on the board, and the perforation rate is 10%. The thickness of the outer high-density FRP is 1.5mm, and the distance between the i...

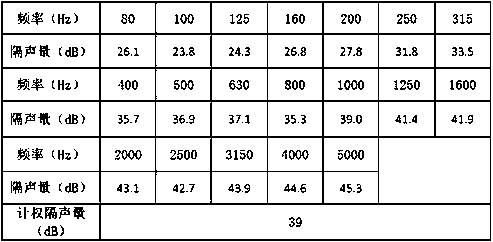

Embodiment 2

[0029] A high-efficiency composite sound insulation board, the sound insulation board adopts a sandwich composite structure, including double-layer high-density FRP, and the middle of the double-layer high-density FRP is filled with aluminum fiber felt. Density FRP and inner high-density FRP.

[0030] The high-density FRP is made of the following raw materials in parts by weight: 95 parts of unsaturated polyester resin, 34 parts of medium-alkali glass fiber, 7 parts of dibenzoyl peroxide, 13 parts of p-hydroxybenzenesulfonic acid, 3 parts of octyl ester, 80 parts of aluminum powder, 0.7 part of organosiloxane, the density of the high-density glass fiber reinforced plastic is 1.4-2.1g / cm 3 .

[0031] The thickness of the high-density FRP on the inner side (that is, the side facing the sound source) is 1.5mm, and microholes with a diameter of 0.5mm are opened on the board, and the perforation rate is 13%. The thickness of the outer high-density FRP is 2mm, and the distance bet...

Embodiment 3

[0034] A high-efficiency composite sound insulation board, the sound insulation board adopts a sandwich composite structure, including double-layer high-density FRP, and the middle of the double-layer high-density FRP is filled with aluminum fiber felt. Density FRP and inner high-density FRP.

[0035] The high-density FRP is made of the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 40 parts of alkali-free glass fiber, 10 parts of zinc stearate, 15 parts of methyl ethyl ketone peroxide, 4 parts of diisononyl phthalate part, 100 parts of clay, 1 part of organosiloxane, and the density of the high-density FRP is 1.4-2.1g / cm 3 .

[0036] The thickness of the high-density FRP on the inner side (that is, the side facing the sound source) is 1.5mm, and microholes with a diameter of 0.8mm are opened on the board, and the perforation rate is 15%. The thickness of the outer high-density FRP is 2.5mm, and the distance between the inner high-densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com