Almond isolated protein modification and dried egg preparation methods

A technology for separating protein and almonds, which is applied in plant protein processing, etc. It can solve the problems of uneven taste and flavor, uneven degassing, high energy consumption, etc., to avoid unstable quality and high energy consumption, and avoid bubbles of different sizes , Improve the effect of amino acid score

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

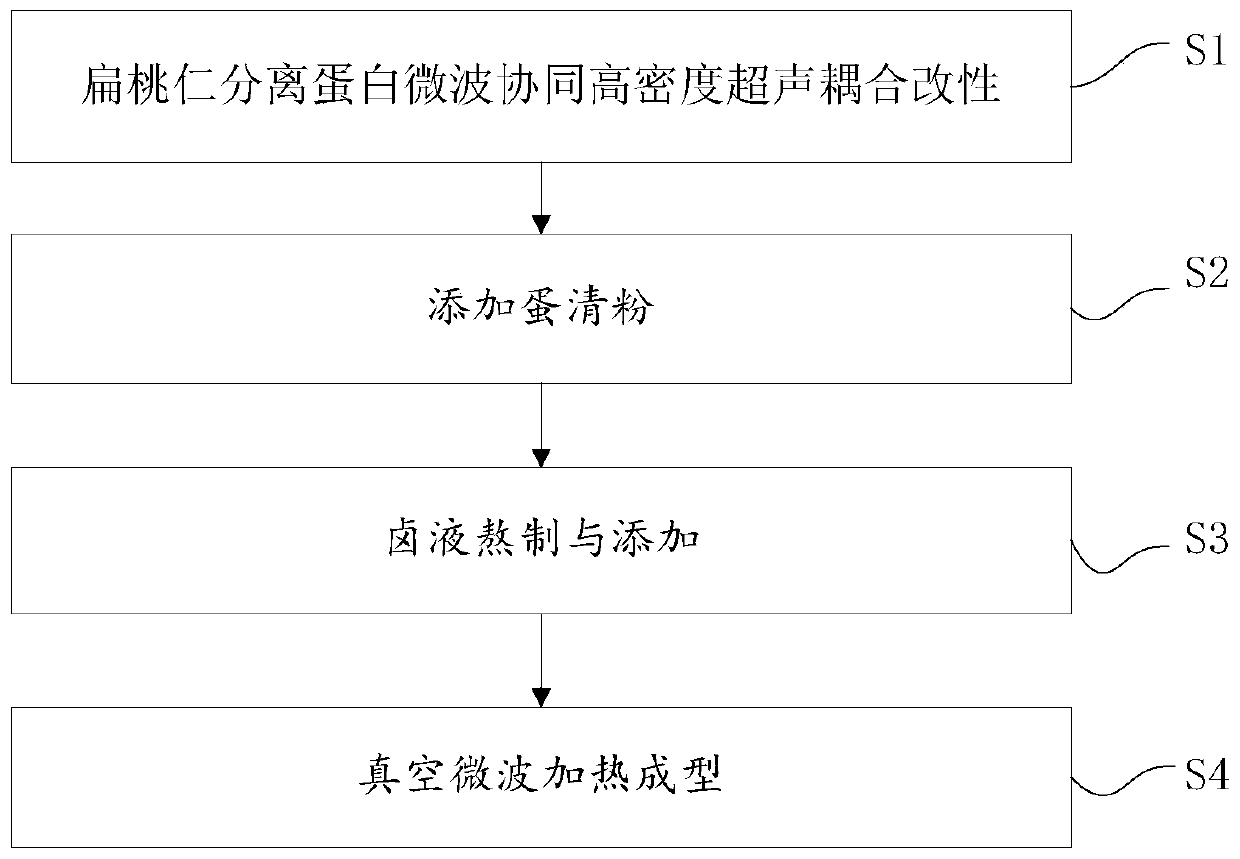

Method used

Image

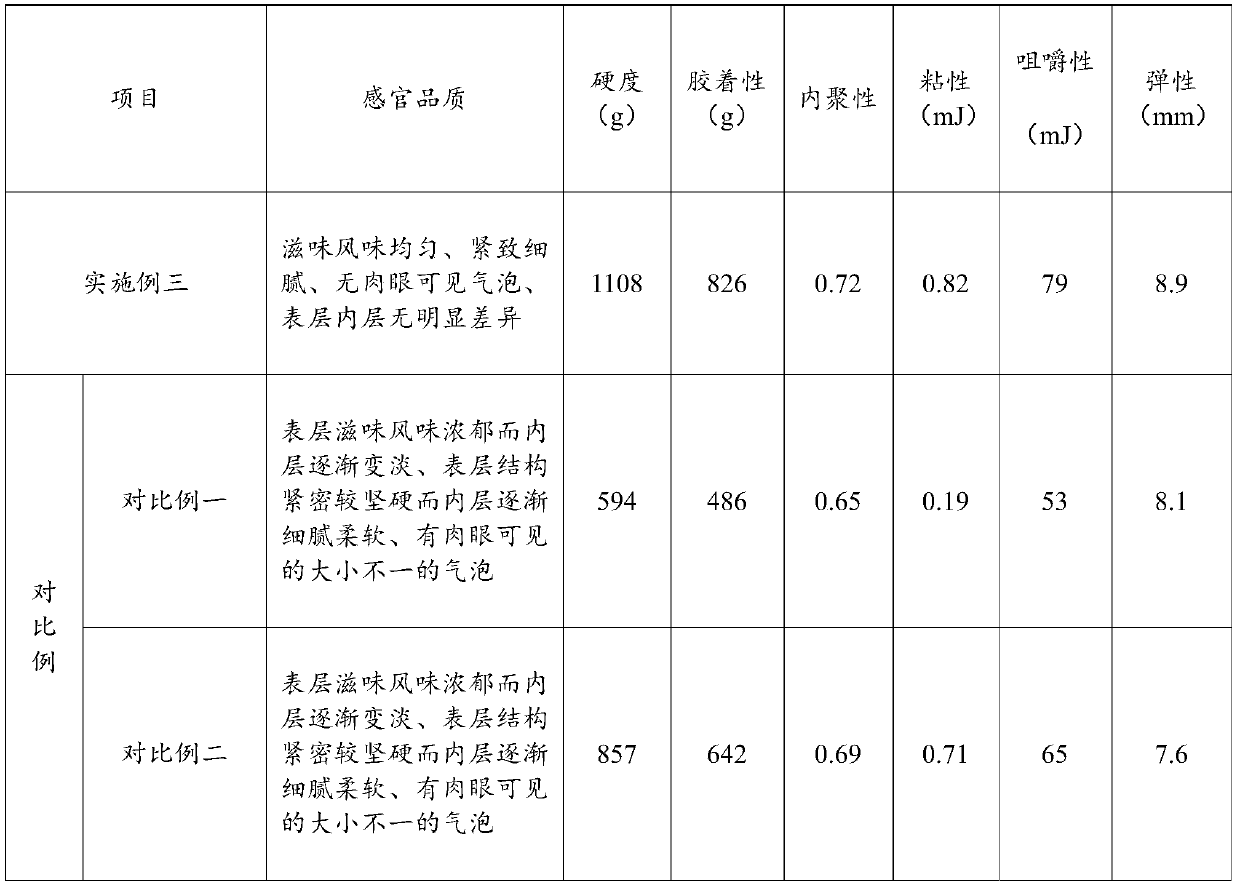

Examples

Embodiment 1

[0037] (1) Modification of almond protein isolate by microwave and high-density ultrasonic coupling: Almond protein isolate powder: distilled water = 1:15, dilute with water, stir at low speed to dissolve, then filter with double gauze, and treat it under a microwave with a power of 800W for 5 seconds , carry out high-density ultrasonic modification treatment, the ultrasonic power is 200W, and the ultrasonic time is 10 minutes (ultrasonic 5 seconds, intermittent 5 seconds).

[0038] (2) Add egg white powder: add 14% egg white powder to the modified almond protein isolate liquid, stir and mix at low speed.

[0039] (3) Brewing and adding of marinade: according to the flavor type of the product, spices are prepared in proportion. The process parameters of boiling and preparing marinade are material-to-liquid ratio 1:18, boil for 160 minutes, use multi-layer gauze for the stew, repeat Filter to remove impurities, add 6% by volume to the mixture of modified almond protein isolate ...

Embodiment 2

[0043] (1) Microwave and high-density ultrasonic coupling modification of almond protein isolate: according to almond protein isolate powder: distilled water = 1:14, dilute with water, stir at low speed to dissolve, filter with double gauze, and microwave at a power of 800W for 5 seconds. Perform high-density ultrasonic modification treatment, ultrasonic power 220W, ultrasonic time 15 minutes (ultrasonic 5 seconds, intermittent 5 seconds).

[0044] (2) Add egg white powder: add 13% egg white powder to the modified almond protein isolate liquid, stir and mix at low speed.

[0045](3) Brewing and adding of marinade: Prepare spices in proportion according to the flavor type of the product, and the process parameters for preparing the marinade are the material-to-liquid ratio of 1:20, and boil for 180 minutes. The boiled solution is repeatedly filtered with multiple layers of gauze to remove impurities, and 8% by volume is added to the mixed solution of modified almond protein iso...

Embodiment 3

[0049] (1) Modification of almond protein isolate by microwave and high-density ultrasonic coupling: Almond protein isolate powder: distilled water = 1:10, dilute with water, stir at low speed to dissolve, filter with double-layer gauze, and treat with 800W microwave for 5 seconds. High-density ultrasonic modification treatment, ultrasonic power 250W, ultrasonic time 15 minutes (ultrasonic 5 seconds, intermittent 5 seconds).

[0050] (2) Add egg white powder: add 12% egg white powder to the modified almond protein isolate liquid, stir and mix at low speed.

[0051] (3) Brewing and adding of marinade: prepare spices in proportion according to the flavor type of the product, and the process parameters for preparing the marinade are the ratio of material to liquid: 1:24, and boil for 200 minutes. The boiled solution is filtered repeatedly with multiple layers of gauze to remove impurities, and added into the mixed solution of the modified almond protein isolate and egg white powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com