A kind of low temperature rapid curing epoxy resin adhesive for relay and its preparation method

An epoxy resin glue, fast curing technology, used in the field of chemical materials, can solve the problem that the relay cannot be used for a long time at a higher temperature, reduce the curing temperature and curing time, etc., achieve excellent mechanical properties, reduce curing temperature and curing The effect of long time, low temperature storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

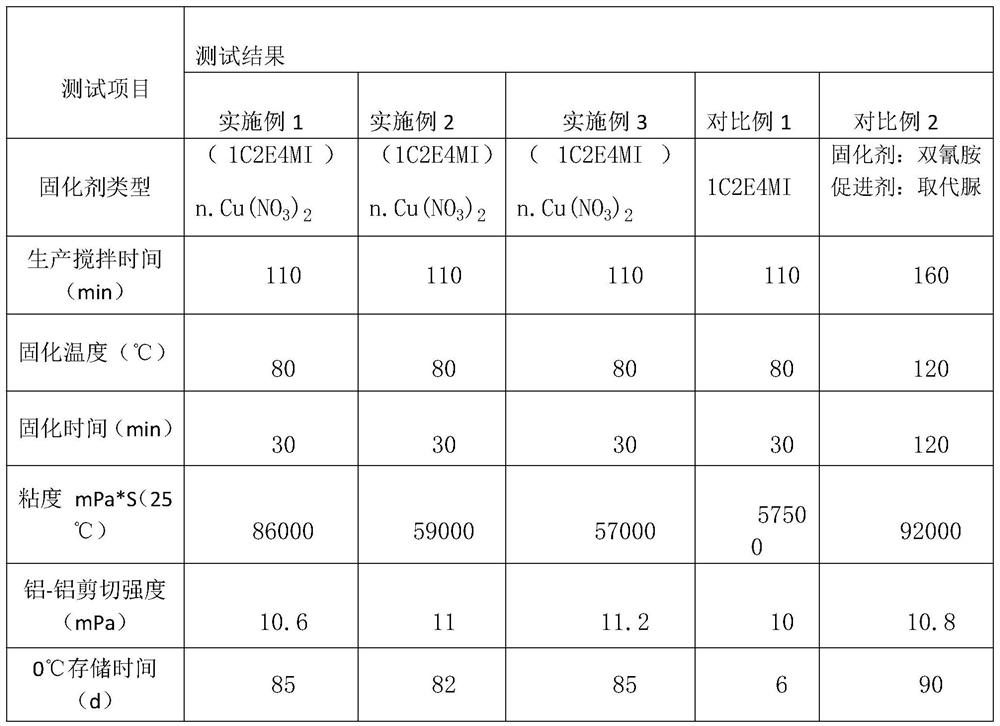

Examples

Embodiment 1

[0023] Embodiment 1: The present embodiment provides a low-temperature fast-curing epoxy resin adhesive for relays and a preparation method thereof, including step S1: preparing 1-cyanoethyl-2-ethyl-4-methylimidazole and metal Copper compound liquid metal complex curing agent (1C2E4MI) n.Cu(NO3)2: the specific steps include adding 1C2E4MI (16.3g, 0.1mol) and acetone (500ml) into a reaction vessel with a condensation recovery device, magnetic Stir well; dissolve copper nitrate (2.7g, 0.02mol) in acetone (50ml) and slowly add the blue copper nitrate-acetone solution to the 1C2E4MI-acetone solution, control the drop rate to 10ml / min, and stir while adding dropwise , after obtaining 1C2E4MI-acetone-copper nitrate solution, it was heated to 50 ° C, reacted for 3 hours and kept stirring, and the acetone was condensed and reclaimed. After the reaction, the solution was cooled to room temperature, and the by-product solid product was separated out. After filtering, the filtrate was dis...

Embodiment 2

[0025] Embodiment 2: A low-temperature fast-curing epoxy resin adhesive for relays and its preparation method provided in this embodiment are basically the same as those in Embodiment 1, except that 45 g of epoxy resin E51 and 12 g of polypropylene glycol are weighed. Diglycidyl ether, 8g liquid metal complex curing agent (1C2E4MI) n.Cu(NO3)2.

Embodiment 3: Embodiment 1 and , and Embodiment 1,:50gE44、5g 2 2 、5gCTBN、33g1250、1.5g。 comparative example 1

[0026] Embodiment 3: A low-temperature fast-curing epoxy resin adhesive for relays and its preparation method provided in this embodiment are basically the same as those in Embodiment 1, except that 50 g of epoxy resin E44 and 5 g of polypropylene glycol are weighed. Diglycidyl ether, 5g of carboxy-terminated CTBN, 33g of 1250-mesh silicon micropowder, and 1.5g of white carbon black. Comparative Example 1: A low-temperature fast-curing epoxy resin adhesive for relays and its preparation method provided in this example, weigh 50 g of epoxy resin E44 and 10 g of carboxyl-terminated CTBN and mix them evenly, and mechanically stir for 10 minutes; 5g of 1C2E4MI and 0.5g of antioxidant BHT were added to the epoxy resin / carboxy-terminated CTBN mixture in turn, and mechanically stirred for 20 minutes; 32g of 600-mesh active aluminum hydroxide and 2.5g of bentonite were added to the above mixture, and mechanically stirred for 60 minutes. Finally, hollow defoaming takes 20-40 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com