Method for rapidly detecting total ginkgolic acid in sample in ginkgo biloba extract production process

A total ginkgolic acid, production process technology, applied in the field of rapid detection of biomass, can solve the problems of affecting the service life of the chromatographic column, large injection volume, overloading of flavonoids and lactones, etc., to achieve short time consumption, reduced use, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1 Preparation method of reference substance solution:

[0065] Refer to the Summary of the Invention for the preparation method of the reference solution.

[0066] 2 Preparation method of the test solution:

[0067] For the preparation method of the test solution, see the Summary of the Invention.

[0068] Accurately draw 5 μl each of the reference solution, the test solution and the positioning control solution respectively, inject it into the liquid chromatograph, calculate the total peak area of the chromatographic peak corresponding to the total ginkgolic acid reference substance in the test solution, and compare it with ginkgoic acid. Calculate the total ginkgolic acid content by the external standard method.

[0069] Use 1.0g, 1.5g and 2.0g of C18 filler to pack the column respectively, carry out sample pretreatment according to 2.1, collect 1mL of 60% ethanol cleaning solution tail liquid before elution with 95% ethanol, filter with 0.22μm filter membrane and...

Embodiment 2

[0071] Use 2.0g of C18 packing to load the column and load the sample until 20mL of 60% ethanol is finished cleaning the residual drug solution. Prepare three samples, and then use 10mL of methanol, 15mL of methanol, 20% of methanol and 25mL of 95% ethanol to wash at a speed of 2mL / min. After the elution and elution were completed, 1 mL of the eluted tail liquid was collected, and directly injected for detection after filtration with a 0.22 μm filter membrane. As a result, total ginkgolic acid was detected in the eluted tail liquid of the first three, and 25 mL of 95% ethanol eluted the tail liquid. Since the pollution of ethanol is less and the waste liquid is easier to handle, it is determined that the eluting solvent is 95% ethanol, and the dosage is 25mL.

Embodiment 3

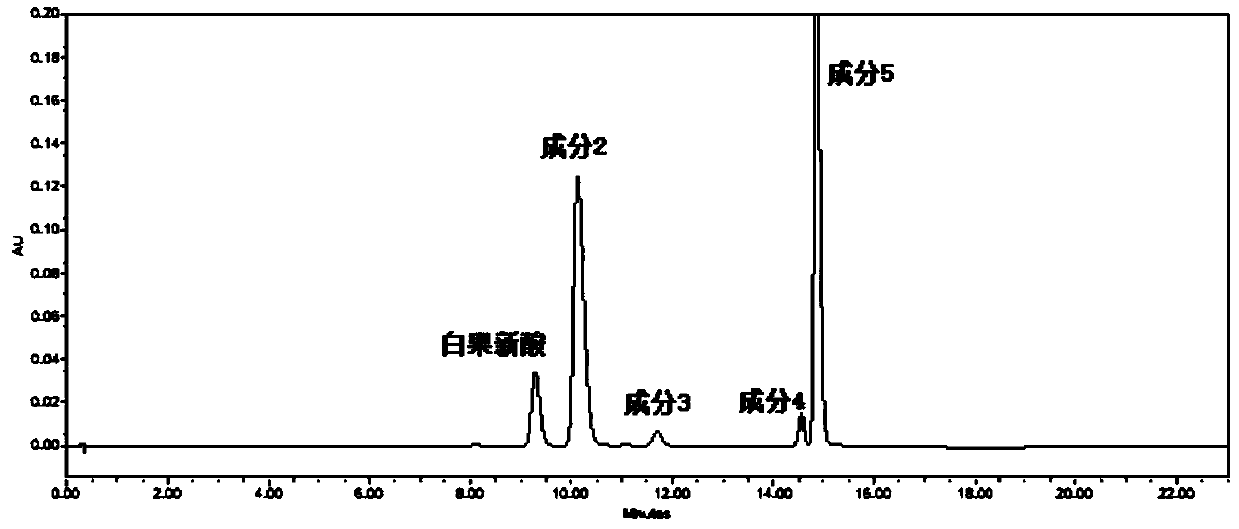

[0073] Chromatographic column with octadecylsilane bonded silica gel (inner diameter 2.1mm, particle size 1.7 / 1.8μm), UV detector / DAD / PDA, λ=310nm, column temperature T=30℃, injection volume : 5 μL, using acetonitrile-0.1% trifluoroacetic acid solution as the mobile phase to carry out gradient elution according to Table 1, the flow rate of the mobile phase is 0.4mL / min, see the chromatogram of the reference solution for positioning figure 1 , the total ginkgolic acid contains ginkgoxinic acid and ingredients 2-5, a total of 5 ingredients.

[0074] Table 1 Gradient elution table

[0075] time / min Acetonitrile (%) 0.1% trifluoroacetic acid (%) 0 65 35 5.5 72 28 10 72 28 15 100 0 18 100 0 18.01 65 35 24 65 35

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com