High thermal conductor and preparation method thereof

A technology of high thermal conductivity and thermal conductivity film, applied in the direction of semiconductor devices, chemical instruments and methods, semiconductor/solid-state device components, etc. problem, to achieve the effect of low density, adjustable thickness and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

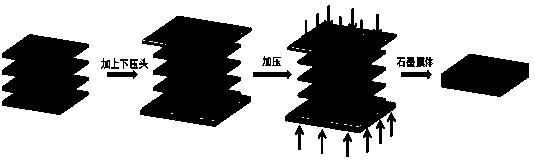

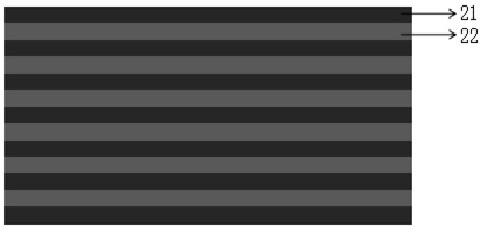

[0033] 1. S101, cutting: prepare 20 reduced graphene oxide films with the same size (9cm×9cm×35μm);

[0034] 2. S102, stacking: stacking the cut graphene film layer by layer to make a graphene film laminate;

[0035] 3. S103, pressurization: place the graphene film laminate in a vacuum hot-press furnace, the size of the upper and lower pressure heads is 10cm×10cm×1cm, and there are arrayed square protrusions on the surface, the height of the protrusions is 5 μm, and the protrusions The side length is 2mm×1mm, the protrusion density is 10 pieces / square centimeter, the vacuum degree is 0.02MPa, and a pressure of 60MPa is applied in the direction perpendicular to the surface of the heat-conducting film laminate, and the pressurization time is 1h to obtain the final High thermal conductivity.

[0036] The density of the high heat conductor formed in this example is 1.96g / cm 3 , the thickness is about 0.5mm, and the plane thermal conductivity is 900W / (m·K). This embodiment shows ...

Embodiment 2

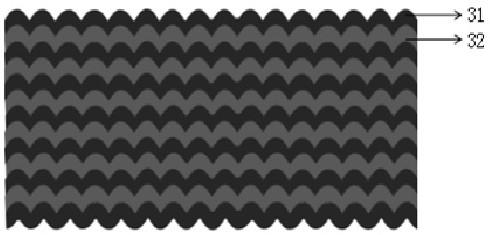

[0038] 1. S101, cutting: prepare 20 pyrolytic graphite films with the same size (30cm×10cm×30μm);

[0039] 2. S102, stacking: stacking 20 prepared graphite films to form a graphite film stack;

[0040] 3. S103, pressurization: place the graphite film laminate in a rolling mill, the size of the upper and lower rolls is φ10*20, and the surface is continuous hemispherical protrusions, the height of the protrusions is 10 μm, the rolling pressure is 100 MPa, and the rolling pressure is 100 MPa. The number of times of manufacturing is 10 times to obtain the final high thermal conductivity body.

[0041] The density of the high heat conductor formed in this example is 1.89g / cm 3 , the thickness is about 0.5mm, and the plane thermal conductivity is 800W / (m·K). This embodiment shows that the high thermal conductor prepared by the present invention has the advantages of low density, adjustable thickness, high temperature resistance, and high thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com