System and method for producing solid carbonate and the solid carbonate

A carbonate and solid technology, applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, chemical instruments and methods, etc., can solve the problems of unfavorable large-scale production, environmental hazards, increased production costs, etc., to improve the efficiency of reaction generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The preparation method of magnesium-containing calcium carbonate provided by the present invention has simple process and low cost, and the prepared magnesium-containing calcium carbonate is a solution rich in nitrogen, magnesium and calcium elements, which can be directly applied to crops as liquid fertilizer, and can also be used as In the preparation of liquid fertilizers, nitrogen, magnesium, and calcium are added to the production and preparation of liquid fertilizers, which can save the cost of liquid fertilizer raw materials, and is conducive to the nutrient supplement and absorption of crops, and is also conducive to improving soil structure and crop quality. .

[0081] The present invention also provides a carbonate solid prepared by the method described in any one of the above, wherein the carbonate solid is at least one of magnesium-containing calcium carbonate, calcium carbonate or magnesium carbonate. Preferably, the magnesium-containing calcium carbonate i...

Embodiment 1

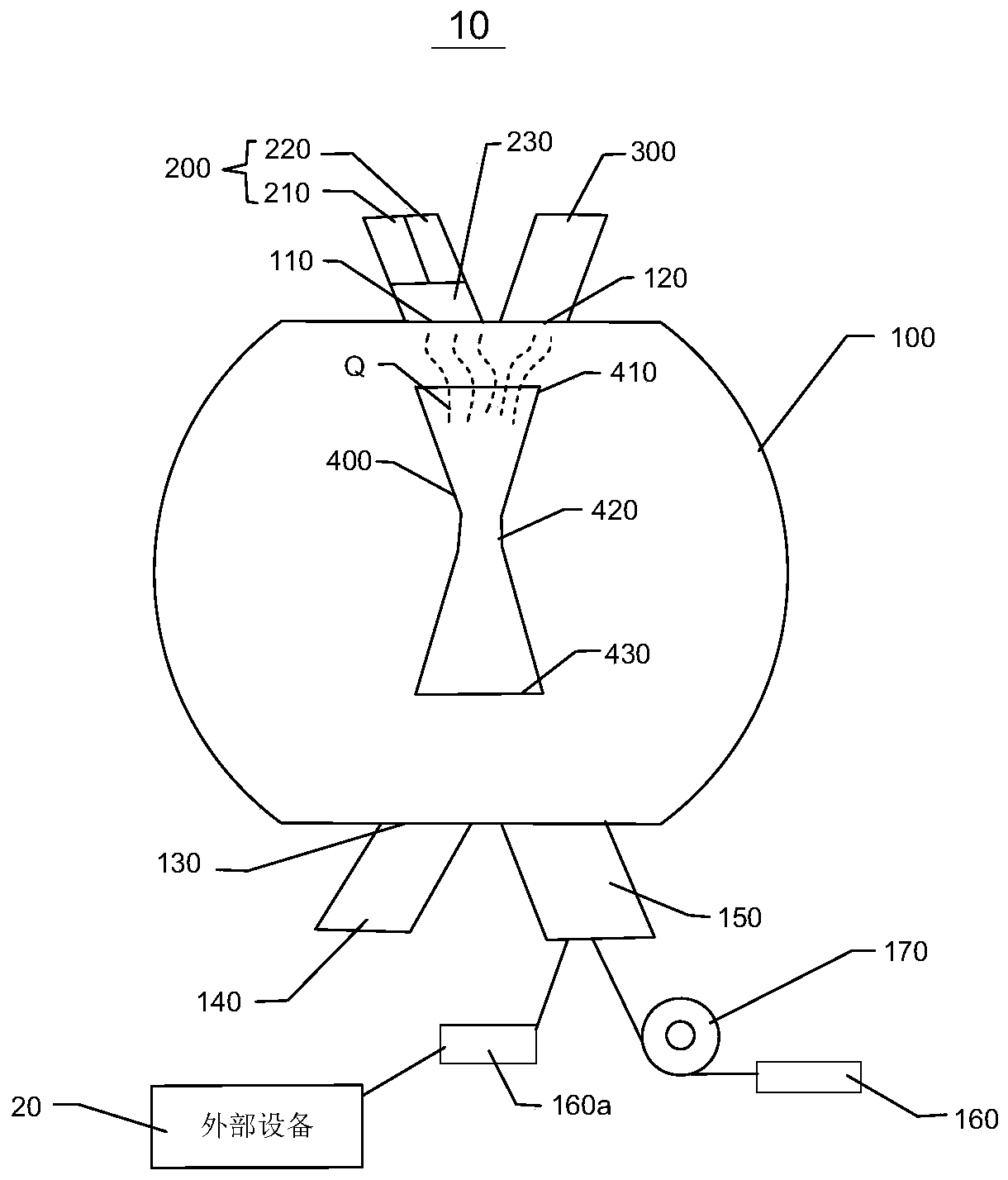

[0087] A kind of method that utilizes above-mentioned embodiment system 10 to produce magnesium-containing calcium carbonate solid, comprises the following steps:

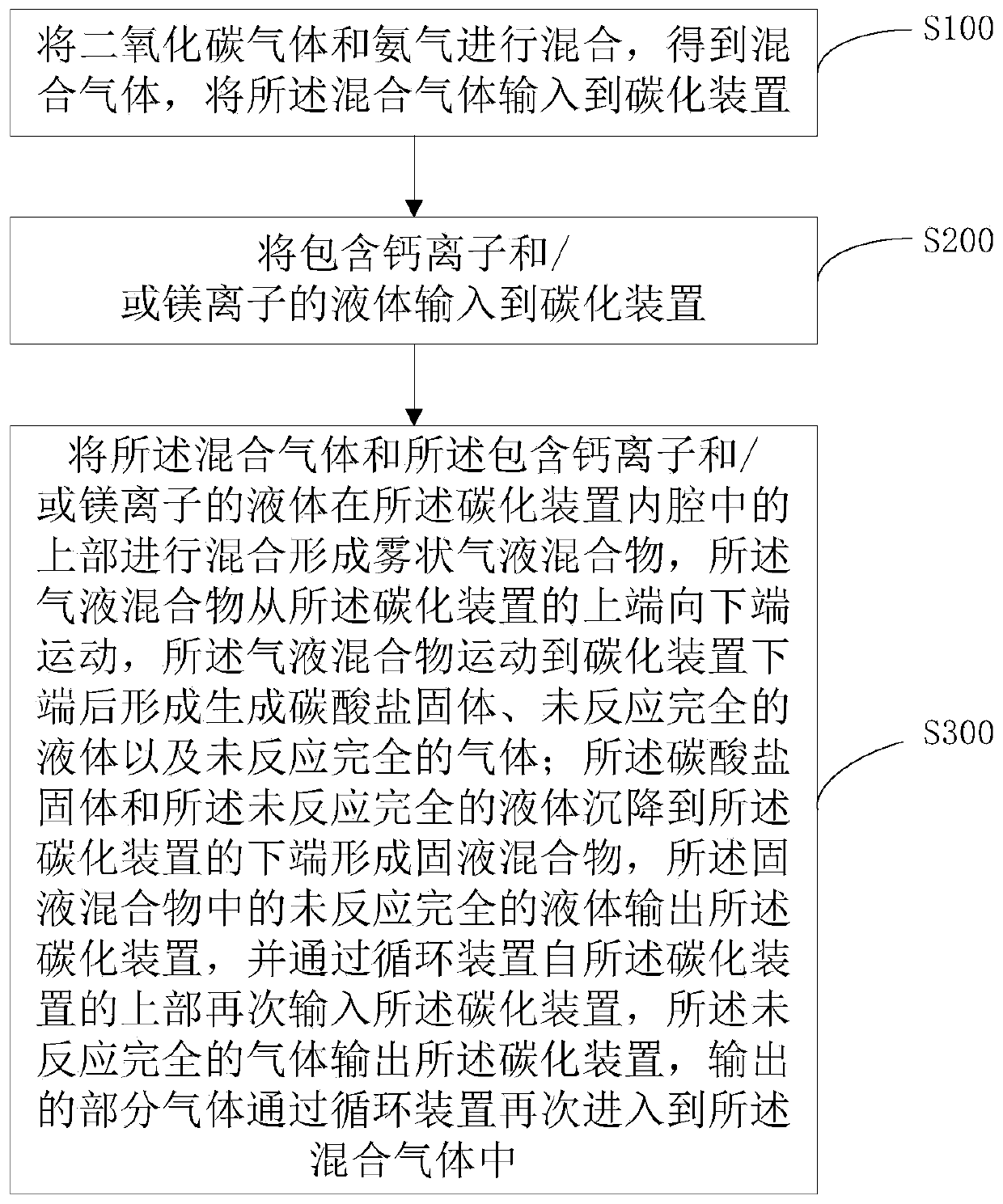

[0088] Pass the phosphate rock calcination tail gas, ammonia gas and nitrate solution into the carbonization device 10 to carry out carbonization reaction, wherein, the nitrate solution is a nitrate solution containing calcium nitrate solution and magnesium nitrate solution, and after carbonization reaction, solid Liquid mixture, using the reflux pump to transport the solid-liquid mixture to the inlet of the gas-liquid mixing device for cyclic carbonization. During the cyclic carbonization process, the solid-liquid mixture is first mixed with nitrate solution, and then mixed with phosphate rock calcination tail gas and ammonia gas , to obtain calcium carbonate containing magnesium. In Example 1, the mass concentration of the nitrate solution is 0.26 tons / ton of water*per hour. In this embodiment, 27 tons of nitrate...

Embodiment 2

[0091] A kind of method that utilizes above-mentioned embodiment system 10 to produce magnesium-containing calcium carbonate solid, comprises the following steps:

[0092] Pass the phosphate rock calcination tail gas, ammonia gas and nitrate solution into the carbonization device 10 to carry out carbonization reaction, wherein, the nitrate solution is a nitrate solution containing calcium nitrate solution and magnesium nitrate solution, and after carbonization reaction, solid Liquid mixture, using the reflux pump to transport the solid-liquid mixture to the inlet of the gas-liquid mixing device for cyclic carbonization. During the cyclic carbonization process, the solid-liquid mixture is first mixed with nitrate solution, and then mixed with phosphate rock calcination tail gas and ammonia gas , to obtain calcium carbonate containing magnesium. In Example 2, the mass concentration of the nitrate solution is 0.22 tons / ton of water*per hour. In this embodiment, 27 tons of nitrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com