Heavy metal polluted wastewater treatment agent, and preparation method and application thereof

A waste water treatment, heavy metal technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problem of large molecular weight of corn peptide, difficult flocculation, and low utilization efficiency of chelating groups and other issues, to achieve the effect of wide sources of raw materials and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

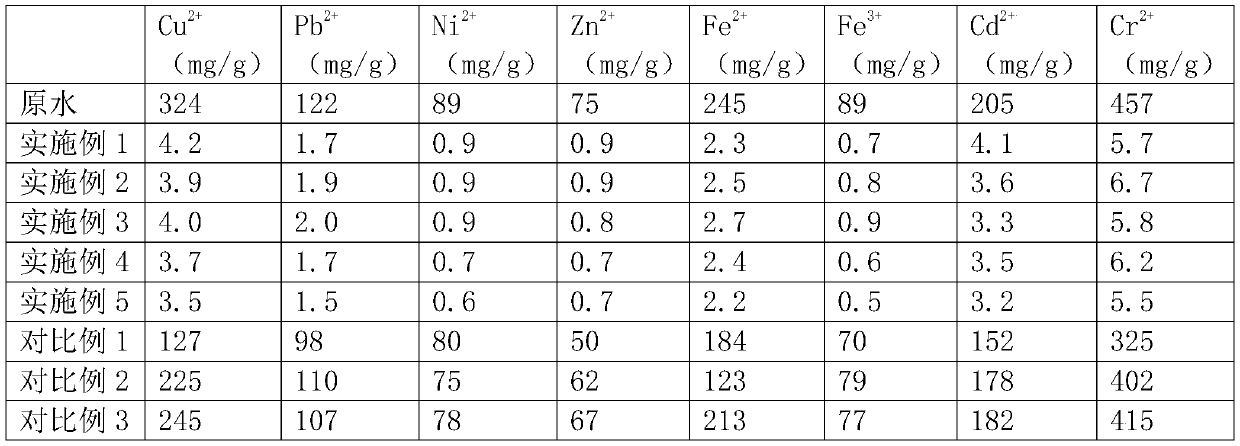

Examples

Embodiment 1

[0020] Composition of raw materials (parts by weight): 15 parts of corn peptide modified by sodium dithiocarbamate, 13 parts of sodium carbonate, 11 parts of calcium hydroxide, and 12 parts of disodium EDTA.

[0021] Corn peptide modified by sodium dithiocarbamate is prepared by the following method: dissolve 30g corn peptide and 10g (0.25mol) NaOH solid in 1000mL water, slowly add 0.225mol CS in a cold water bath 2 , control the reaction temperature below 40°C, after the dropwise addition, raise the temperature to 40°C and stir for 1 hour to obtain the corn peptide modified by sodium dithiocarbamate, with a yield of 85% based on corn peptide.

[0022] The preparation method of heavy metal polluted wastewater treatment agent is characterized in that it comprises the following steps: dissolving corn peptide modified by sodium dithiocarbamate in water, adding sodium carbonate while stirring at 500r / min to form solution A; mixing disodium EDTA Dissolve in water, heat up to 40°C, ...

Embodiment 2

[0024] Composition of raw materials (parts by weight): 20 parts of corn peptide modified by sodium dithiocarbamate, 17 parts of sodium carbonate, 15 parts of calcium hydroxide, and 25 parts of disodium EDTA.

[0025] Corn peptide modified by sodium dithiocarbamate is prepared by the following method: dissolve 50g corn peptide and 10g (0.25mol) NaOH solid in 1000mL water, slowly add 0.275mol CS in a cold water bath 2 , control the reaction temperature below 40°C, after the dropwise addition, raise the temperature to 60°C and stir for 3 hours to obtain corn peptide modified by sodium dithiocarbamate, with a yield of 90% based on corn peptide.

[0026] The preparation method of heavy metal polluted wastewater treatment agent is characterized in that it comprises the following steps: dissolving corn peptide modified by sodium dithiocarbamate in water, adding sodium carbonate while stirring at 700r / min to form solution A; mixing disodium EDTA Dissolve in water, heat up to 60°C, add...

Embodiment 3

[0028] Composition of raw materials (parts by weight): 17 parts of corn peptide modified by sodium dithiocarbamate, 14 parts of sodium carbonate, 12 parts of calcium hydroxide, and 15 parts of disodium EDTA.

[0029] The corn peptide modified by sodium dithiocarbamate is prepared by the following method: dissolve 35g corn peptide and 10g (0.25mol) NaOH solid in 1000mL water, slowly add 0.24mol CS in a cold water bath 2 , control the reaction temperature below 40°C, after the dropwise addition, raise the temperature to 45°C and stir for 2 hours to obtain the corn peptide modified by sodium dithiocarbamate, with a yield of 89% based on corn peptide.

[0030] The preparation method of heavy metal polluted wastewater treatment agent is characterized in that it comprises the following steps: dissolving corn peptide modified by sodium dithiocarbamate in water, adding sodium carbonate while stirring at 550r / min to form solution A; mixing disodium EDTA Dissolve in water, heat up to 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com