Anti-cracking impervious concrete

A technology of concrete and fly ash, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of demanding maintenance environment, difficulty in controlling expansion rate of expansion agent, unfavorable cost control and sustainable development To achieve the effect of improving the heat release rate of hydration and the surface energy of the pore solution, eliminating temperature stress and drying shrinkage cracks, and good anti-plastic shrinkage surface crack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

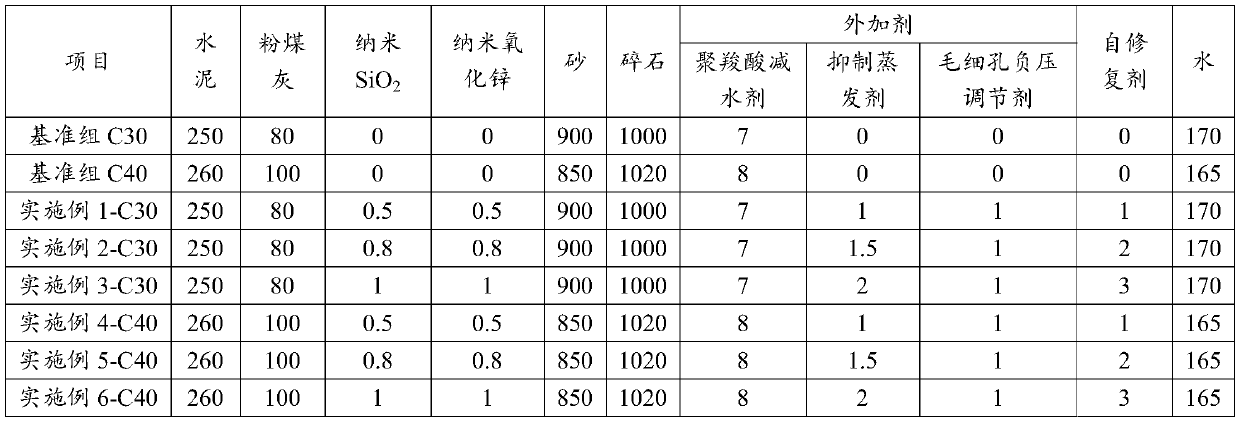

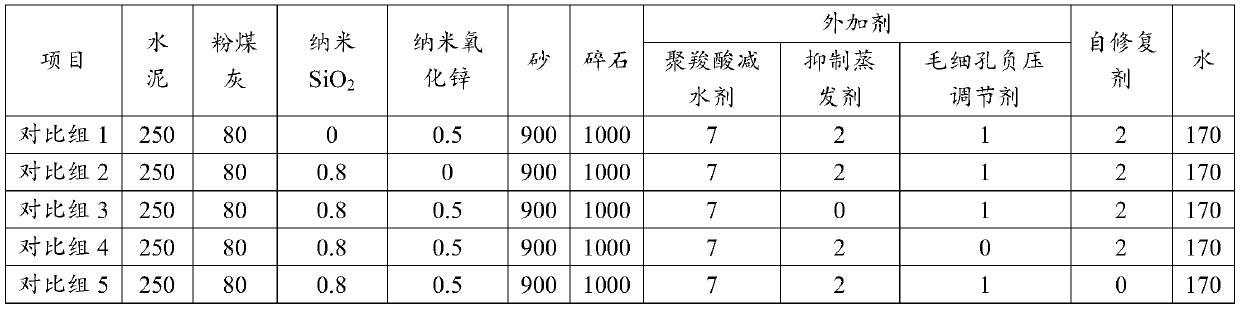

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] In the following examples:

[0029] Cement: Ordinary Portland cement P·O 42.5, fineness 330~350m 2 / kg;

[0030] Fly ash: Class I fly ash, activity index 70%, water requirement ratio 90%, fineness 5%;

[0031] Sand: the sand in the machine-made sand zone II, the particle throughput of the 300μm sieve is 20% to 25%;

[0032] Crushed stone: 5~31.5mm crushed stone, continuous grading, mud content ≤0.2%;

[0033] Nano inorganic oxide: nano SiO 2 , the mass ratio of the particle diameter of 50-150nm to the particle diameter of 200-400nm is 3:7.

[0034] Nano Zinc Oxide: The particle size is 200-400nm.

[0035] Admixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com