Preparation method of diisocaprylic acid tin oxide complex

A technology of diisooctanoic acid and stannous isooctanoate, which is applied in tin organic compounds, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., can solve problems such as preparation methods of unseen compounds, and eliminate pollution , The preparation method is simple, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

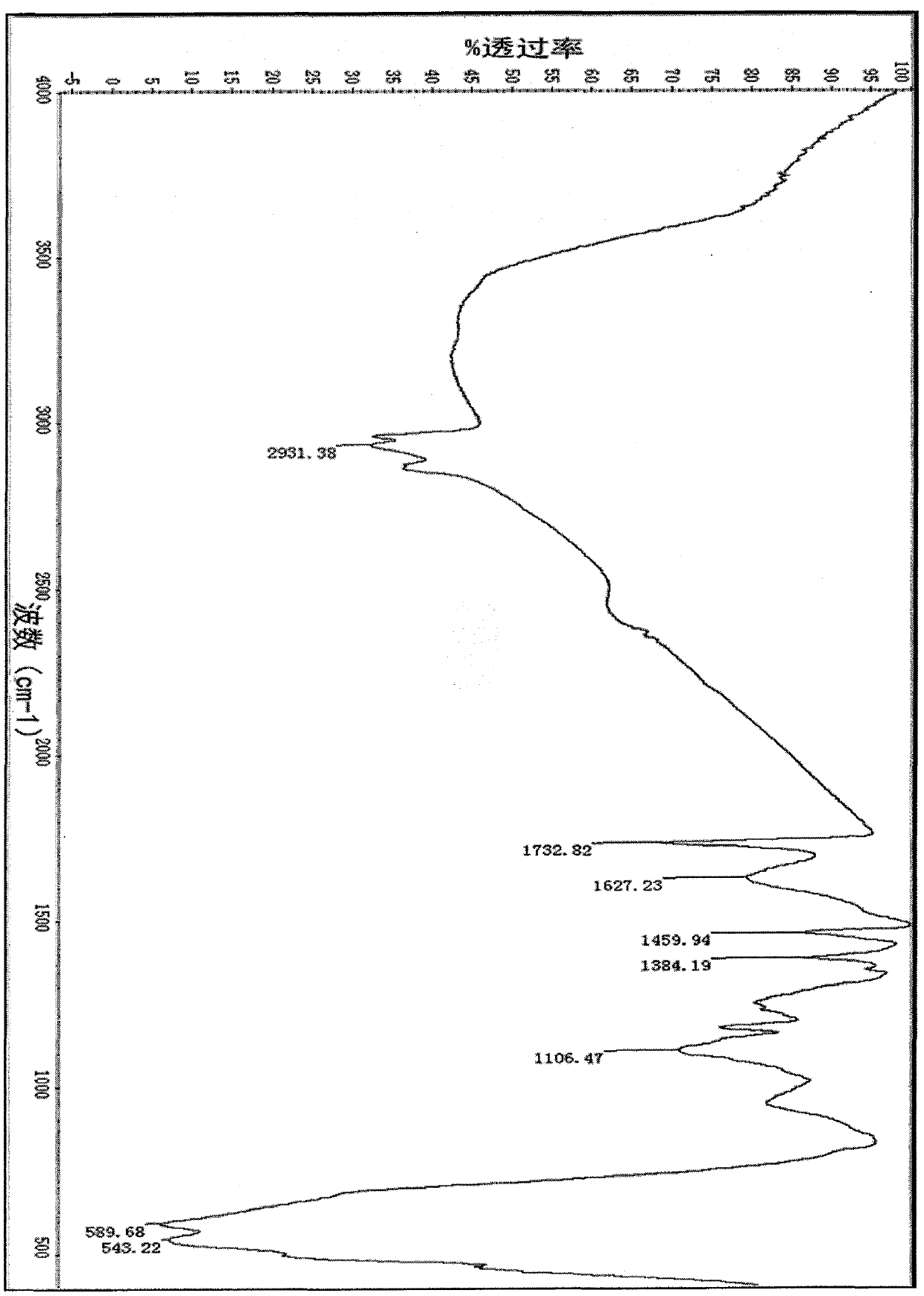

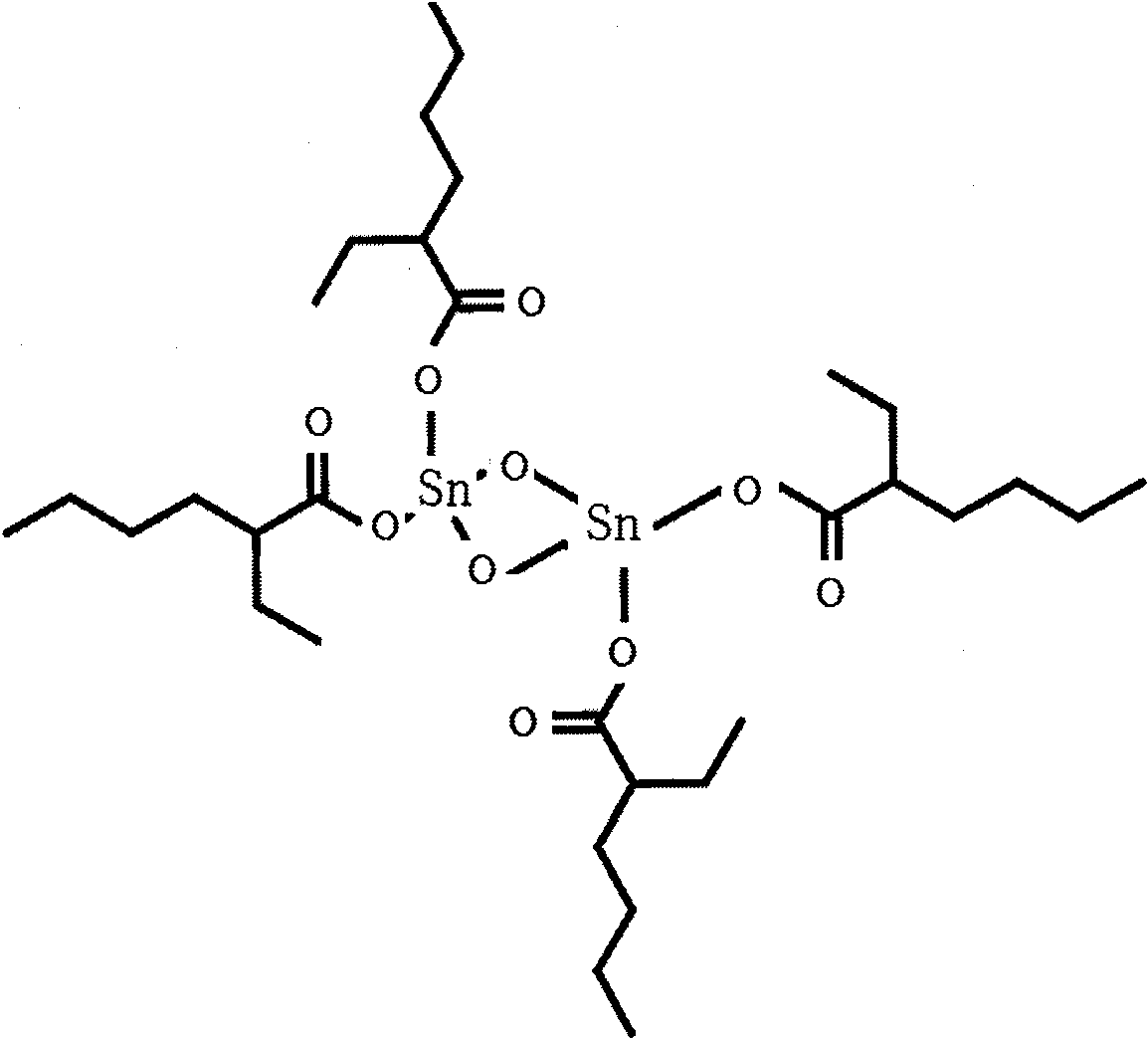

Image

Examples

Embodiment 1

[0031] A kind of diisooctanoic acid tin oxide complex is prepared according to the following method:

[0032] Add solvent and tin source compound into the reaction kettle, react with excess isooctanoic acid at 180°C, react for 2 hours, remove excess isooctanoic acid under reduced pressure, lower the temperature below 100°C, add 15% sodium hydroxide solution, and stir React for 0.5h, let it stand for 15min to separate layers, separate the lower layer of alkaline water and solid product; then collect the alkaline water and solid product in a stirred tank and let it settle for 2 hours, after the solid settles at the bottom of the tank, take out the alkaline solution, and add ethanol to the solid Stir evenly, filter, add butyl acetate to the filter cake, stir evenly, filter with a tin-containing adsorption fiber membrane, and dry the filter cake to obtain a tin oxide complex of diisooctanoate.

[0033] The described tin-containing adsorption fiber membrane is prepared according to...

Embodiment 2

[0040] A kind of diisooctanoic acid tin oxide complex is prepared according to the following method:

[0041]Add solvent and tin source compound into the reaction kettle, react with excess isooctanoic acid at 250°C, react for 10 hours, remove excess isooctanoic acid under reduced pressure, lower the temperature below 100°C, add 40% sodium hydroxide solution, and stir React for 2 hours, let it stand for 45 minutes to separate layers, and separate the lower layer of alkaline water and solid product; then collect the alkaline water and solid product in a stirred tank and let it settle for 5 hours. Uniformly, filter, add butyl acetate to the filter cake and stir evenly, use a tin-containing adsorption fiber membrane to filter, and dry the filter cake to obtain diisooctanoic acid tin oxide complex.

[0042] The described tin-containing adsorption fiber membrane is prepared according to the following method: 400Kg of ethyl acetate, 100Kg of polymethyl methacrylate, 0.5Kg of dimethyl...

Embodiment 3

[0049] A kind of diisooctanoic acid tin oxide complex is prepared according to the following method:

[0050] Add solvent and tin source compound into the reaction kettle, react with excess isooctanoic acid at 225°C, react for 5 hours, remove excess isooctanoic acid under reduced pressure, lower the temperature below 100°C, add 25% sodium hydroxide solution, and stir React for 1 hour, let it stand for 30 minutes to separate the layers, and separate the lower layer of alkaline water and solid product; then collect the alkaline water and solid product in a stirred tank and let it settle for 4 hours. Uniformly, filter, add butyl acetate to the filter cake and stir evenly, use a tin-containing adsorption fiber membrane to filter, and dry the filter cake to obtain diisooctanoic acid tin oxide complex.

[0051] The described tin-containing adsorption fiber membrane is prepared according to the following method: 600Kg of ethyl acetate, 100Kg of polymethyl methacrylate, 3Kg of dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com