Preparation method of cashew nut oil modified waterborne acrylic acid modified alkyd resin dispersion

A water-based acrylic and alkyd resin technology, applied in coatings, primers, etc., can solve problems such as slow drying speed, complex synthesis process, and poor water resistance, and achieve fast drying speed, simple operation, and excellent product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

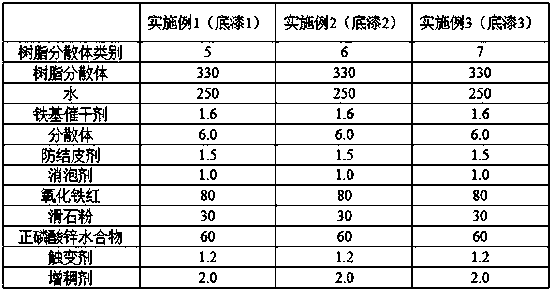

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] (1) Synthesis of cashew nut oil phenolic resin: put 56.4g of phenol and 120g of cashew nut oil in a closed flask equipped with a thermometer, condensation separator and stirring device, add acidic catalyst sulfuric acid aqueous solution, and then add 70.5 g formaldehyde with a volume fraction of 37%, heated to 98-100°C, refluxed for 3 hours, and vacuum dehydrated to 130°C to obtain cashew oil modified phenolic resin;

[0032] (2) Synthesis of cashew oil modified alkyd resin prepolymer: put 640g of linseed oil and 135.2g of pentaerythritol in a closed flask equipped with a thermometer, condensation separator and stirring device, raise the temperature to 120°C, and add 0.384g LiOH, heat up to 240°C for alcoholysis, alcoholysis until the reaction solution (1 part of sample: 9 parts of 95% ethanol) is transparent, cool down to 100°C, add 251.4g of phthalic anhydride, add xylene to reflux, quickly heat up to 180°C for es...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036](1) Synthesis of cashew nut oil phenolic resin: put 56.4g of phenol and 120g of cashew nut oil in a closed flask equipped with a thermometer, condensation separator and stirring device, add acidic catalyst sulfuric acid aqueous solution, and then add 70.5 Formaldehyde with a volume fraction of g of 37% is heated to 98-100°C, and after reflux for 3 hours, it is vacuum dehydrated to 130°C to obtain a cashew nut oil modified phenolic resin;

[0037] (2) Synthesis of cashew oil-modified alkyd resin prepolymer: 564g tall oleic acid, 160g trimethylolpropane, 48g neopentyl glycol and 152g hexahydrophthalic anhydride were placed in a thermometer, condensing water separator In a closed flask with a stirring device, the temperature was raised to 160°C for 1 hour of esterification, and then the temperature was raised to 250°C at a rate of 10°C per hour, kept at 250°C, esterified to an acid value of 8mgKOH / g, and cooled to 100°C...

Embodiment 3

[0040] This embodiment includes the following steps:

[0041] (1) Synthesis of cashew nut oil phenolic resin: put 56.4g of phenol and 120g of cashew nut oil in a closed flask equipped with a thermometer, condensation separator and stirring device, add an acid catalyst sulfuric acid aqueous solution, and then add 70.5g of Formaldehyde with a volume fraction of 37%, heated to 98-100°C, refluxed for 3 hours, vacuum dehydrated at 130°C, to obtain cashew nut oil modified phenolic resin;

[0042] (2) Synthesis of cashew oil-modified alkyd resin prepolymer: 335g soy oil, 86g trimethylolpropane, 95g neopentyl glycol, 21g maleic anhydride and 146g isophthalic acid were placed in a thermometer with a thermometer , condensing water separator and stirring device in a closed flask, the temperature was raised to 160°C for esterification for 1 hour, and then the temperature was raised to 250°C at a rate of 10°C per hour, kept at 250°C, esterified to an acid value of 8 mgKOH / g, and cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com