A kind of preparation method of silicon-strontium alloy modifier

A modifier and alloy technology, applied in the field of alloy metal materials, can solve the problems of high cost and difficult process, and achieve the effects of reducing production cost, reducing process difficulty and promoting inoculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the silicon-strontium alloy modifier provided by the present invention comprises the following steps:

[0022] (1) Dry the monocrystalline silicon cutting material or polycrystalline silicon cutting material until the moisture content is below 1%;

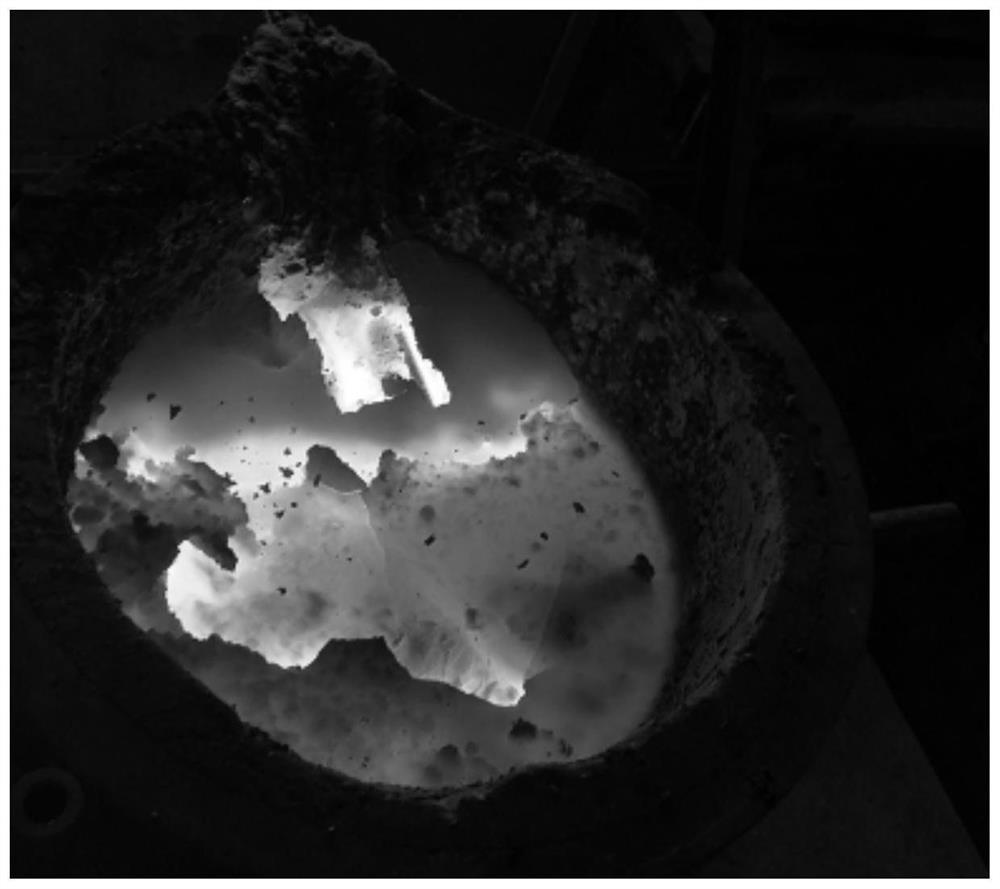

[0023] (2) Mix 80-100 parts by weight of the dried monocrystalline silicon cutting material or polycrystalline silicon cutting material with 20-30 parts by weight of scrap steel, and conduct electric heating smelting at 1300-1450 ℃ to obtain alloy liquid;

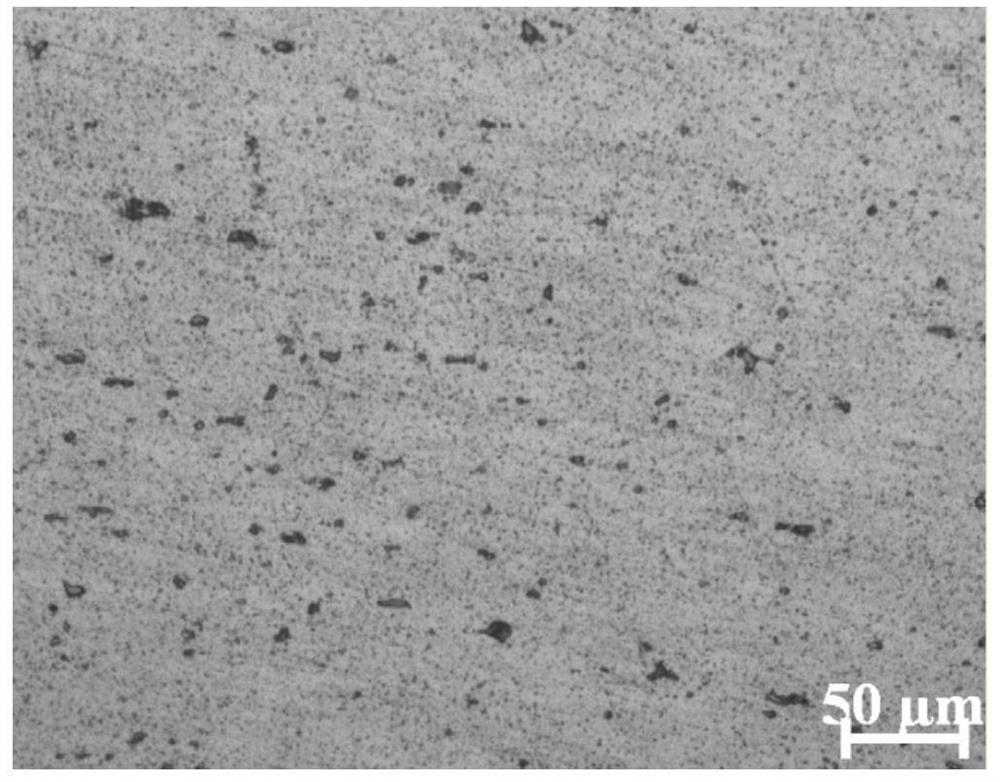

[0024] (3) adding the obtained alloy liquid to 1-4 parts by weight of metal strontium, to carry out a strontium alloying reaction, and then casting and molding to obtain a silicon-strontium alloy modifier. As can be seen from the above description, the beneficial effects of the present invention are:

[0025] The present invention adopts the electric heating smelting technology through the design of the above-mentioned preparation process. The s...

Embodiment 1

[0035] The preparation method of the silicon-strontium alloy modifier of the present embodiment comprises the following steps:

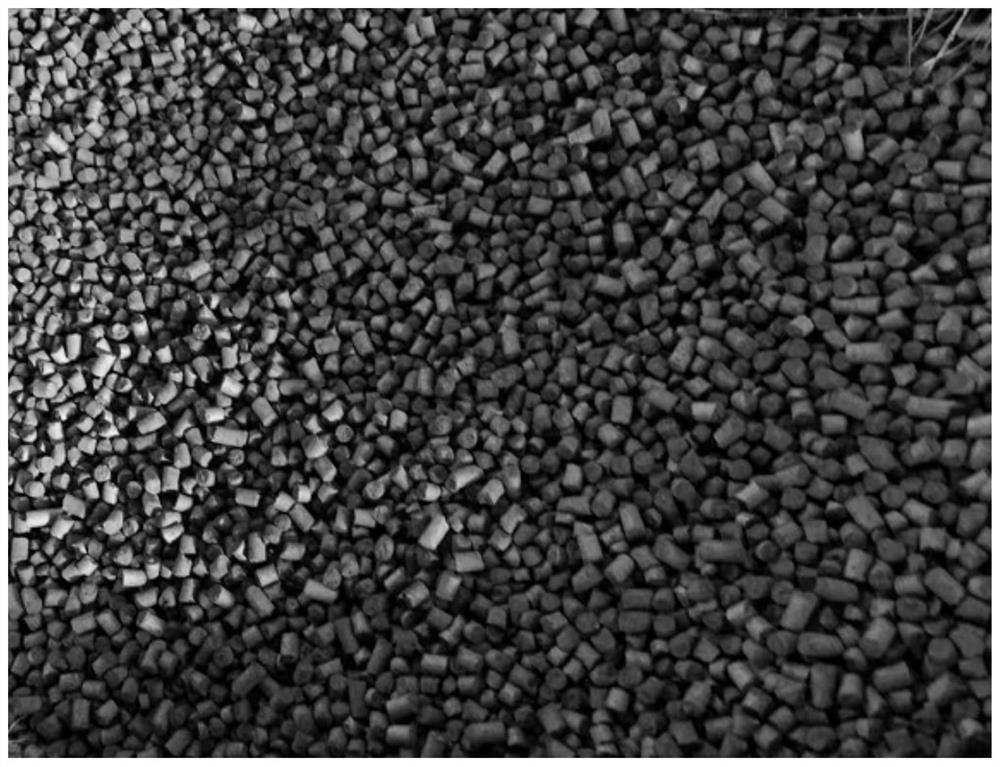

[0036] The high-purity water-containing silicon fume scraps produced in the slicing process of solar-grade mono / polycrystalline silicon plates are used as raw materials, and the extruded granulation is carried out in the extruder to obtain the granulated material, and the obtained granulated material is put into the rotary drying kiln , dry at 80℃ until moisture ≤1.0%, 3-12mm material in the granulation material accounts for more than 90%, put the weighed metal strontium on the bottom of the secondary heating furnace to avoid the pouring point and cover it with a covering agent it is good. The above raw material formula is 80 parts by weight of dried mono / polycrystalline silicon wafer cutting powder granules, 20 parts by weight of clean scrap steel, and 1 part by weight of metal strontium, and the temperature of the melting furnace is controlled with...

Embodiment 2

[0039] The preparation method of the silicon-strontium alloy modifier of the present embodiment comprises the following steps:

[0040]The high-purity water-containing silicon fume scraps produced in the slicing process of solar-grade mono / polycrystalline silicon plates are used as raw materials, and the extruded granulation is carried out in the extruder to obtain the granulated material, and the obtained granulated material is put into the rotary drying kiln , dried at 150 °C until moisture ≤ 1.0%, 3-12mm material accounted for more than 90% of the granulated material, put the weighed metal strontium on the bottom of the secondary heating furnace to avoid the pouring point and cover it with a covering agent it is good. The above raw material formula is 100 parts by weight of dried mono / polycrystalline silicon wafer cutting powder granules, 30 parts by weight of clean scrap steel, and 4 parts by weight of metal strontium, and the temperature of the melting furnace is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com