Air-water linkage device for underground coal mine drilling

A feng shui linkage, coal mine technology, used in safety devices, mining equipment, earthwork drilling and other directions, can solve the problems of increased nozzle holes, gas explosion, serious environmental pollution, etc., and achieve the best slag discharge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

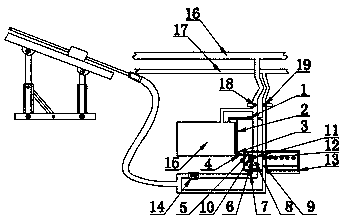

[0020] see figure 1 As shown, the technical scheme adopted in this specific embodiment is: it includes the water supply valve 1 of the stabilized water tank, the water level gauge of the stabilized water tank 2, the water level observation valve of the stabilized water tank 3, the purification filter device 4, the needle-shaped trace liquid valve 5, the water distribution valve Switch 6, water distribution nozzle of compressed air system 7, control switch of compressed air slag discharge system 8, control switch of hydraulic slag discharge system 9, trace liquid flowmeter 10, air pressure gauge of compressed air system 11, water pressure gauge of water supply system 12, drilling rig operation System instrumentation and control valve 13, check valve 14, stabilized pressure water storage tank 15, described stabilized pressure water storage tank 15 is connected with pressurized air pipeline 16 and water supply pipeline 17 and has the water level gauge 2 of stabilized pressure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com