Negative electrode slurry, negative electrode plate and preparation method of negative electrode plate

A negative electrode slurry and dry material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low peel strength of electrode sheets, poor low-temperature discharge and cycle performance of lithium-ion batteries, and improve flexibility And peel strength, good wetting, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The embodiment of the present application also provides the preparation method of the above-mentioned negative electrode slurry. The preparation method is to first dissolve part of the acrylonitrile multi-polymer emulsion and the water-based thickener to form a mixed glue, and then mix the remaining acrylonitrile multi-polymer The late addition of the pulp process mainly includes the following steps:

[0051] Dissolve the water-based thickener and part of the acrylonitrile multi-polymer emulsion in water to form a glue;

[0052] Mixing the active material and the conductive agent evenly and adding the glue for the first dispersion to obtain the first dispersion;

[0053] Adding the remaining acrylonitrile multi-polymer copolymer emulsion, heat-melted ethylene carbonate, and the first amount of water to the first dispersion for second dispersion to obtain a second dispersion;

[0054] Adding styrene-butadiene latex or styrene-acrylic latex and a second amount of water t...

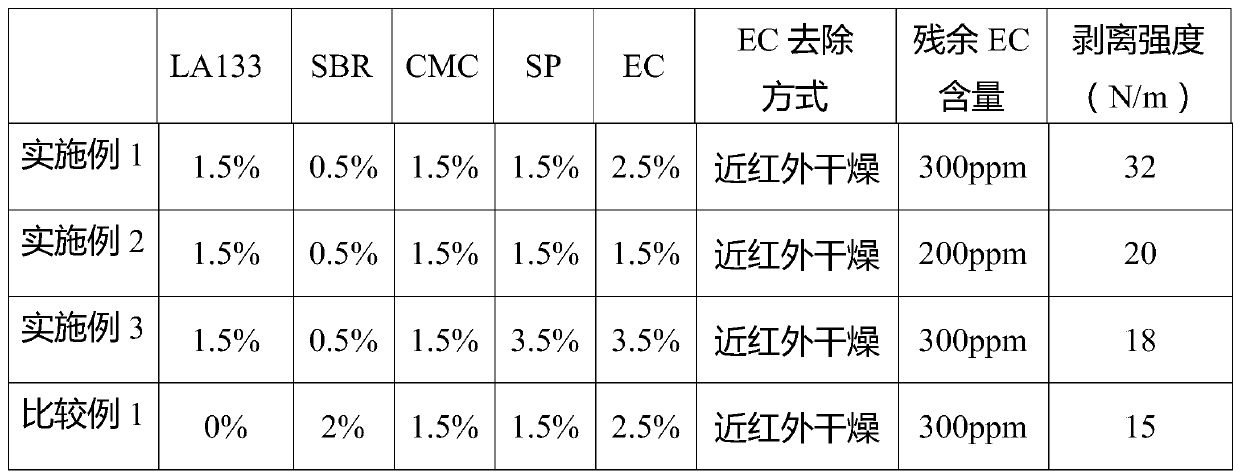

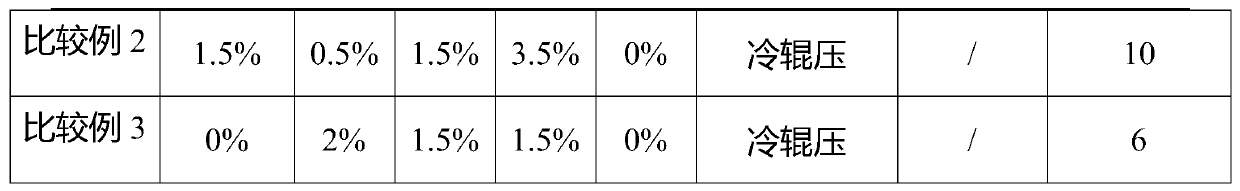

Embodiment 1

[0073] Material selection: artificial graphite (Kaijin New Energy Technology Co., Ltd.), LA133 (produced by Chengdu Dayi Yindile Battery Material Co., Ltd., with a viscosity of 7300mpa.s~10000mpa.s), styrene-butadiene latex (SBR, BASF, Germany , the model is Binder21-11ap, the second binding agent of the following embodiments is all selected styrene-butadiene latex as an example), sodium carboxymethyl cellulose (CMC, Shanghai Daicel Plastic Industry Co., Ltd.), conductive agent SP (TIMCAL ) and ethylene carbonate (EC, Xianghe Kunlun Chemical Co., Ltd.).

[0074]Preparation of negative electrode slurry: first dissolve CMC and part of LA133 (30% of the total weight of LA133) in water to prepare glue, control the viscosity of the glue to 7000mpa.s, filter and set aside; heat-melt EC , stand-by; add artificial graphite and SP in the slurry mixing kettle, under the condition that the online speed is 16rpm, stir for 15min, and mix evenly; add the prepared glue in the slurry mixing k...

Embodiment 2

[0080] The selection of material: with embodiment 1.

[0081] Preparation of the negative electrode slurry: same as in Example 1, wherein the weight of ethylene carbonate added is 1.5% of the total weight of the negative electrode slurry.

[0082] Preparation of the negative electrode sheet: the method steps are the same as in Example 1, the difference is that the content of the components left on the negative electrode sheet after the negative electrode slurry is dried is different, and the residual EC content of the negative electrode sheet after winding is calibrated by gas chromatography to be 200ppm . The components left on the negative plate after the negative electrode slurry is dried include: 95% artificial graphite; 1.5% LA133 dry material; 0.5% SBR dry material; 1.5% CMC; 1.5% sp.

[0083] Preparation of lithium-ion battery: Cut the positive electrode sheet of Example 1 and the negative electrode sheet of Example 2, laminate them together with the ceramic separator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com