Cultivation method of beech mushroom, white beech mushroom, seafood mushroom, lyophyllum decastes and needle mushrooms

A cultivation method and technology of white jade mushroom, applied in mushroom cultivation, botany equipment and method, cultivation, etc., can solve the problems of low production efficiency and high production cost, and achieve the effects of increased efficiency, reduced height and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

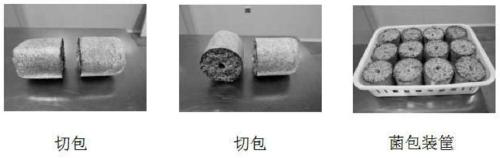

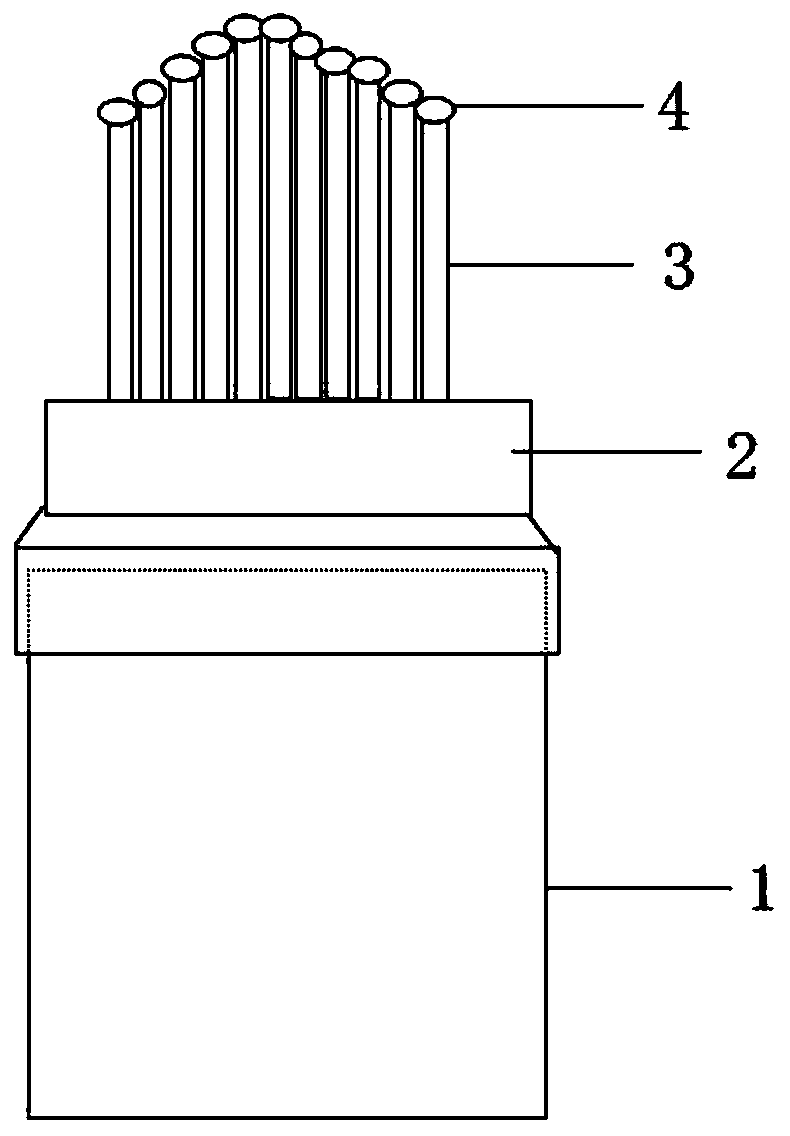

[0038] The cultivation method of crab-flavored mushroom may further comprise the steps:

[0039] (1) Ingredients: 50% cottonseed hulls, 25% sawdust, 15% wheat bran, 2% soybean meal, 3.5% soybean hulls, 3.5% beet pulp, and 1% lime.

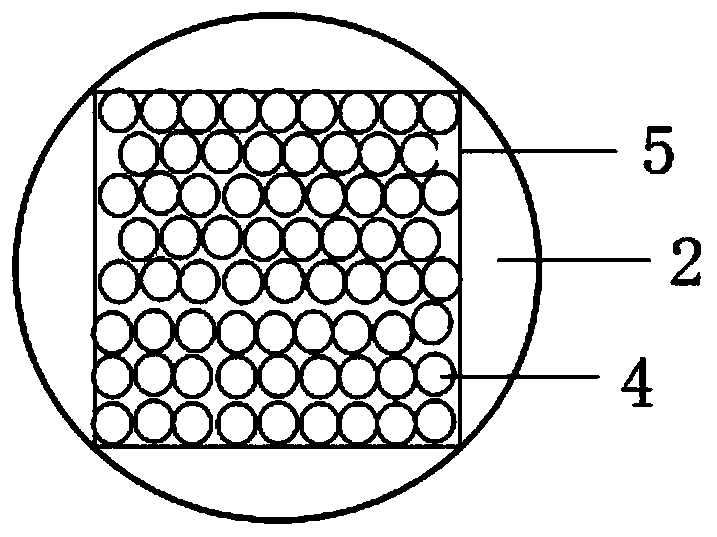

[0040] (2) Bagging: Use a 17cm×37cm high-pressure resistant polyethylene bag, use an automatic bacterial packaging bag machine combined with a fully automatic numerical control nesting machine for bagging, the bagging material is 18cm high, 10.5cm in diameter, 1.2kg in wet weight, and has a water content of 65 %, the charging amount is to add 73g of cultivation material per 100ml volume, the diameter of the inoculation rod is 2cm, and the insertion depth is 17cm.

[0041] (3) Sterilization: under the pressure of 0.115MPa, the material temperature is kept at 121°C for 2 hours, and cooled to 25°C after sterilization.

[0042] (4) Inoculation: pull out the inoculation rod, use an automatic inoculation machine to inoculate, inoculate 25ml of liquid ba...

Embodiment 2

[0047] The cultivation method of white jade mushroom may further comprise the steps:

[0048] (1) Ingredients: 50% cottonseed hulls, 25% sawdust, 15% wheat bran, 2% soybean meal, 3.5% soybean hulls, 3.5% beet pulp, and 1% lime.

[0049] (2) Bagging: Use a 17cm×37cm high-pressure polyethylene bag, and use an automatic bacterial packaging bag machine combined with a fully automatic numerical control nesting machine for bagging. The bagging material is 20cm high, 10.5cm in diameter, 1.3kg in wet weight, and has a water content of 65. %, the charging amount is to add 73g of planting material per 100ml volume, the diameter of the inoculation rod is 2cm, and the insertion depth is 19cm.

[0050] (3) Sterilization: under the pressure of 0.115MPa, the material temperature is kept at 121°C for 2 hours, and cooled to 25°C after sterilization.

[0051] (4) Inoculation: pull out the inoculation rod, use an automatic inoculation machine to inoculate, inoculate 25ml of liquid bacteria, and...

Embodiment 3

[0056] The cultivation method of seafood mushroom comprises the following steps:

[0057] (1) Ingredients: 50% cottonseed hulls, 25% sawdust, 15% wheat bran, 2% soybean meal, 3.5% soybean hulls, 3.5% beet pulp, and 1% lime.

[0058] (2) Bagging: Use a 17cm×37cm high-pressure polypropylene bag, use an automatic bacterial packaging bag machine combined with a fully automatic numerical control nesting machine for bagging, the bagging material is 22cm high, 10.5cm in diameter, 1.4kg in wet weight, and has a water content of 65 %, the charging amount is to add 73g of cultivation material per 100ml volume, the diameter of the inoculation rod is 2.2cm, and the insertion depth is 21cm.

[0059] (3) Sterilization: under the pressure of 0.115MPa, the material temperature is kept at 121°C for 2 hours, and cooled to 25°C after sterilization.

[0060] (4) Inoculation: pull out the inoculation rod, use an automatic inoculation machine to inoculate, inoculate 25ml of liquid bacteria, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com