Method for producing boric anhydride by adopting cored medium-frequency induction furnace

An induction furnace, intermediate frequency technology, applied in the direction of boron oxide, boron oxide compound, etc., can solve the problems of complex boron anhydride process equipment, high unit energy consumption, low production efficiency, etc., to achieve low labor intensity, low energy consumption, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

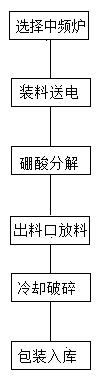

Image

Examples

Embodiment 1

[0027] Described a kind of method that adopts cored intermediate frequency induction furnace to produce boric anhydride, its steps are as follows:

[0028] (1) When using a 1-ton cored intermediate frequency induction furnace to produce boric anhydride, the iron core or metal cylinder core set in the cored intermediate frequency induction furnace is heated to become a heat source for melting boric acid;

[0029] (2) Loading: Load boric acid into the cored intermediate frequency induction furnace, put boric acid into the cored intermediate frequency induction furnace to the production height, and supply power to the cored intermediate frequency induction furnace for production;

[0030] (3) Power transmission production: When the temperature in the cored intermediate frequency induction furnace reaches 400 degrees Celsius, open the plug at the discharge port and continue heating;

[0031] (4) When the temperature in the cored intermediate frequency induction furnace reaches 750...

Embodiment 2

[0034] Described a kind of method that adopts cored intermediate frequency induction furnace to produce boric anhydride, its steps are as follows:

[0035] (1) When using a 1-ton cored intermediate frequency induction furnace to produce boric anhydride, the iron core or metal cylinder core set in the cored intermediate frequency induction furnace is heated to become a heat source for melting boric acid;

[0036] (2) Loading: Load boric acid into the cored intermediate frequency induction furnace, put boric acid into the cored intermediate frequency induction furnace to the production height, and supply power to the cored intermediate frequency induction furnace for production;

[0037] (3) Power transmission production: When the temperature in the cored intermediate frequency induction furnace reaches 400 degrees Celsius, open the plug at the discharge port and continue heating;

[0038] (4) When the temperature in the cored intermediate frequency induction furnace reaches 850...

Embodiment 3

[0041] Described a kind of method that adopts cored intermediate frequency induction furnace to produce boric anhydride, its steps are as follows:

[0042] (1) When using a coreless intermediate frequency induction furnace to produce boric anhydride, it is necessary to modify the coreless intermediate frequency induction furnace with a core.

[0043] (2) When using a 1-ton modified coreless intermediate frequency induction furnace to produce boric anhydride, the iron core or metal cylinder core set in the modified coreless intermediate frequency induction furnace is heated to become a heat source for melting boric acid;

[0044] (3) Charging: Boric acid is loaded into the modified coreless intermediate frequency induction furnace, boric acid is put into the modified coreless intermediate frequency induction furnace to the production height, and the modified coreless intermediate frequency induction furnace is powered for production;

[0045] (3) Power transmission production: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com