Efficient synthesis method of weight-reducing component tartronic acid in cucumbers

A technique for the synthesis of tartronic acid, which is applied in chemical instruments and methods, preparation of carboxylate salts, and preparation of organic compounds, etc., can solve the problems that tartronic acid is difficult to meet market demand, and solve the problem of raw material sources , Simple operation, avoiding the effect of high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for efficiently synthesizing weight loss ingredient propanedioic acid in cucumber, comprising the following steps:

[0023] S1, raw material mixing: add aminomalonic acid and alkenoic acid into the flask for mixing;

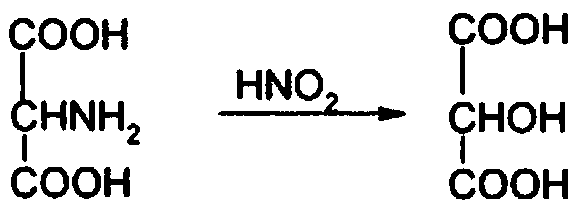

[0024] S2, aminomalonic acid carry out diazotization reaction with sodium nitrite in dilute acid;

[0025] S3, after the diazotization reaction is completed, directly heat up and hydrolyze without separation, and then concentrate under reduced pressure to a solid;

[0026] S4, adding alcohol to desalt, recovering alcohol, and obtaining the crude product of tartronic acid;

[0027] S5. The crude product of tartronic acid is dissolved with acid, decolorized by filtration, and the acid is recovered to obtain tartronic acid.

[0028] In said S2, the diazotization reaction temperature is controlled at -5-10°C.

[0029] In S2, the acid used for diazotization is hydrochloric acid or sulfuric acid.

[0030] In said S3, the hydrolysis temperature is co...

Embodiment 1

[0036] In a 500ml three-necked flask, add 60g of aminomalonic acid and 300mL of 2mol / L hydrochloric acid, stir to dissolve and cool down to about 5°C, add 100g of a 40% aqueous solution of sodium nitrite dropwise, and heat it up to 80°C for about 1 hour when no bubbles come out. Make it fully react completely; Concentrate until the colloid is dissolved in anhydrous methanol and filter to remove sodium chloride; Dissolve the crude product in acetic acid, filter, decolorize and recover the acetic acid to obtain colorless crystals, filter to obtain white crystals of 2-hydroxymalonic acid; bake 52g of crystals were obtained, and the yield was 86.7%. Mp160.5°C (decomposition).

Embodiment 2

[0038] In a 500ml three-neck flask, add 60g of aminomalonic acid and 300mL of 2mol / L sulfuric acid, stir to dissolve and cool down to about 5°C, add 100g of a 40% aqueous solution of sodium nitrite dropwise, and heat it up to 80°C for about 1 hour when no bubbles come out. Make it fully react completely; Concentrate until the colloid is dissolved in anhydrous methanol and filter to remove sodium chloride; Dissolve the crude product in acetic acid, filter, decolorize and recover the acetic acid to obtain colorless crystals, filter to obtain white crystals of 2-hydroxymalonic acid; bake 55g of crystals were obtained, and the yield was 91.7%. Mp160.0°C (decomposition).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com