Preparation method of alkali-resistant yellow disperse dye

A disperse dye, yellow technology, applied in the direction of dyeing, azo dyes, organic dyes, etc., can solve the problems of insufficient alkali resistance, insufficient oxidation resistance and stability, difficult to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

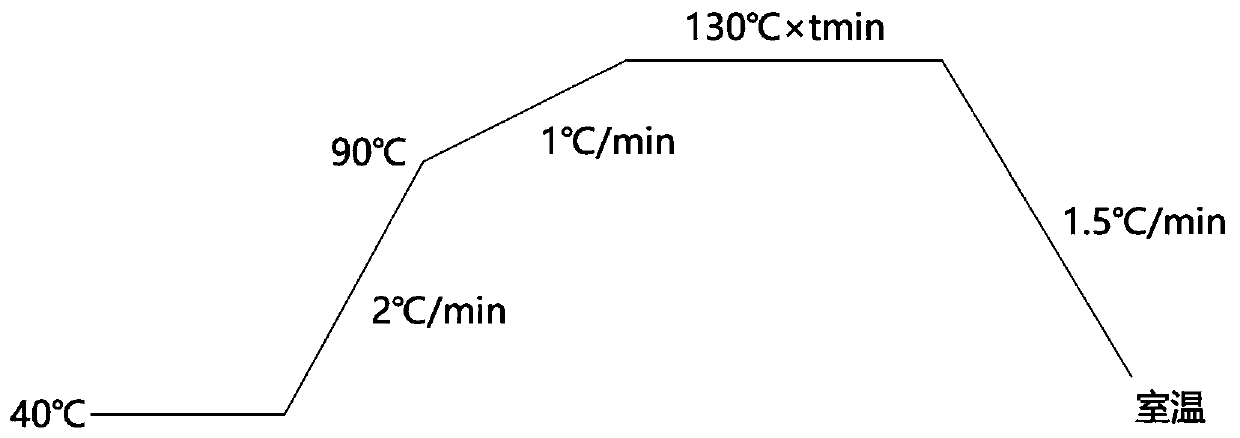

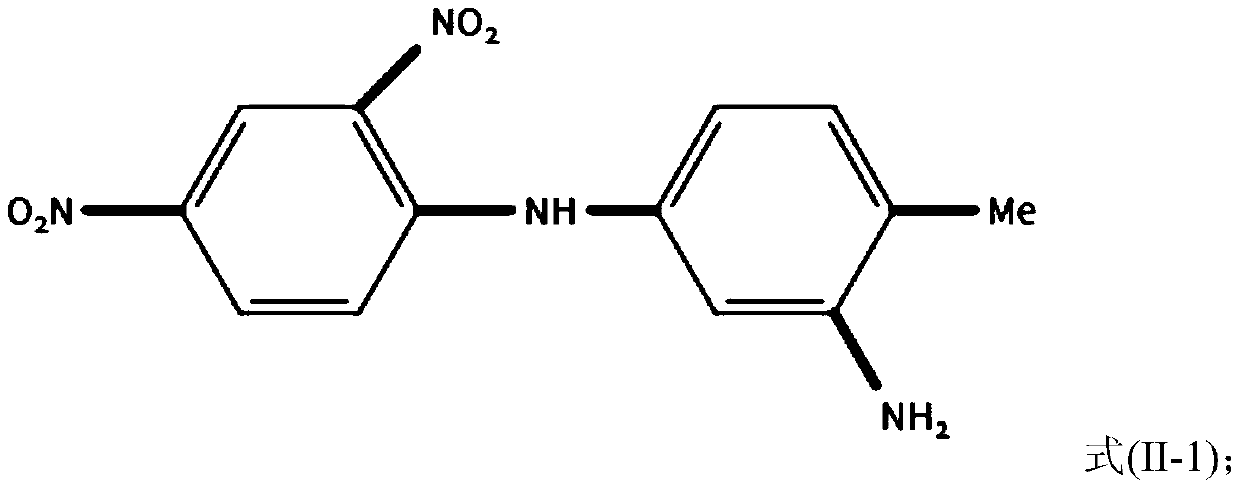

[0051] Add 4.9 g of 2,4-diaminotoluene, 7.4 g of 2,4-dinitrofluorobenzene, 20 g of N,N-diisopropylethylamine and 120 mL of absolute ethanol into a three-necked flask, and heat to reflux for 24 hours. After the reaction, cool to room temperature, filter; wash with distilled water 3 times, and dry to obtain 10.6 g of orange solid (92% yield in this step), namely the compound of formula (II-1).

[0052]

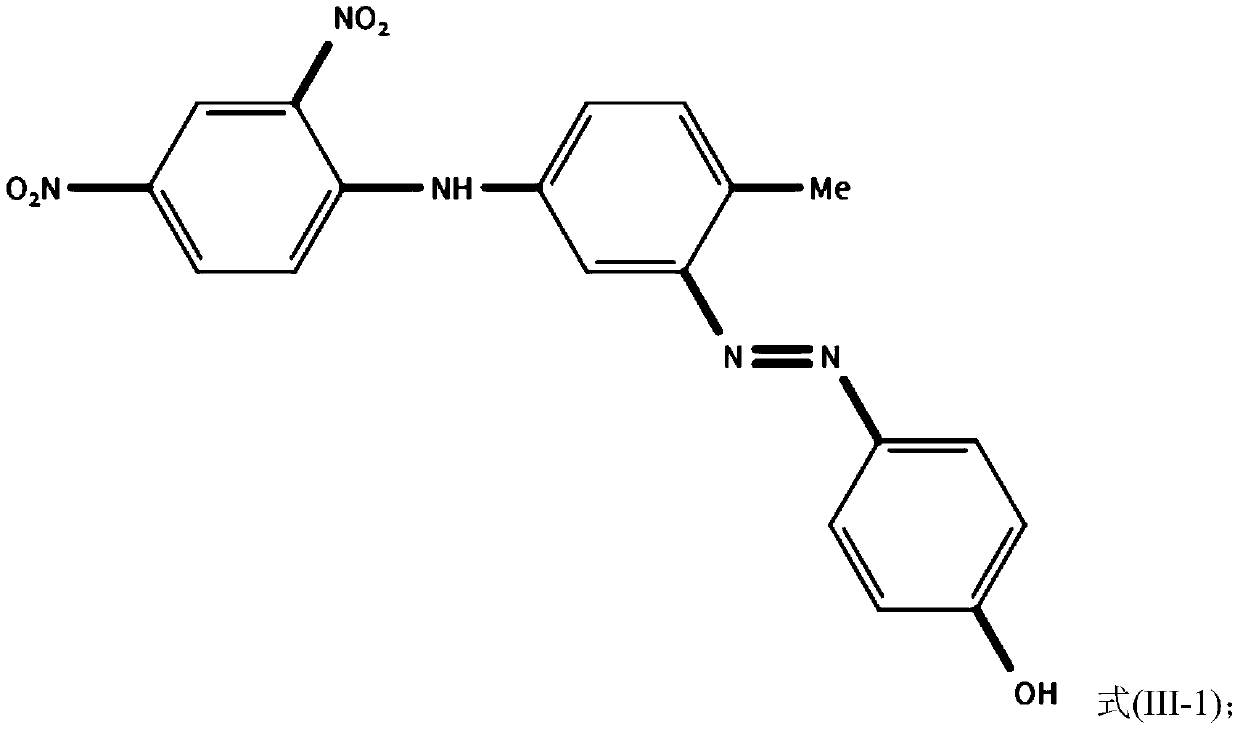

[0053] Add the compound of formula (II-1) and appropriate amount of water into another three-necked flask, and stir at room temperature for 1 h. Add ice to cool down to 0-5°C, add 14.3g of 30wt% hydrochloric acid under heat preservation conditions, and stir well for 2h. At 0-5°C, 12.1 g of a 25 wt % sodium nitrite solution was continuously added dropwise, and after the dropwise addition was completed, the mixture was incubated for 4 hours. Add sulfamic acid to remove excess sodium nitrite, use starch potassium iodide test paper to detect that it does not turn blue in 3-5 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com