Epoxy resin adhesive for bonding rubber materials and formula thereof

A technology of epoxy resin and rubber material, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of thixotropy in pot life, insufficient toughness of adhesive, difficult to control room temperature curing, etc., to improve weather resistance and High and low temperature resistance, good mechanical properties and adhesive properties, the effect of intense molecular motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

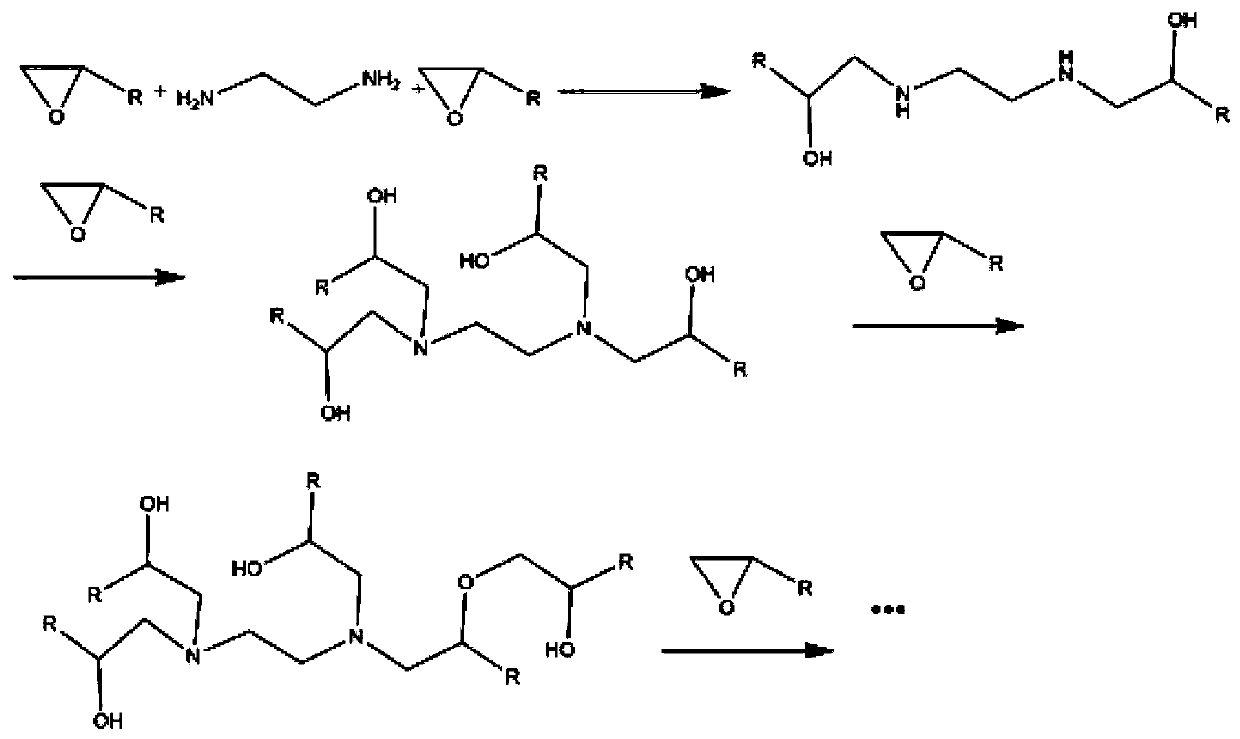

Method used

Image

Examples

Embodiment 1

[0054] A kind of epoxy resin adhesive formula that is used for rubber material bonding of the present invention, comprises A component, B component and hydrophilic silica, the quality of described A component, B component and hydrophilic silica The ratio is 100:40-55:1-8, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0055] The mass ratio of component A, component B and hydrophilic silica in this example is 100:40:6. In another embodiment it is 100:50:1 and in another embodiment it is 100:55:8.

[0056] The viscosity of the A component is 120000cps, and the density is 1.07g / cm 3 , Epoxy value 0.35mol / 100g, it is light yellow transparent viscous liquid.

[0057] The viscosity of the B component is 7800cps, and the density is 0.95g / cm 3 , the amine value is 380mgKOH / 100g, it is light brown transparent viscous liquid.

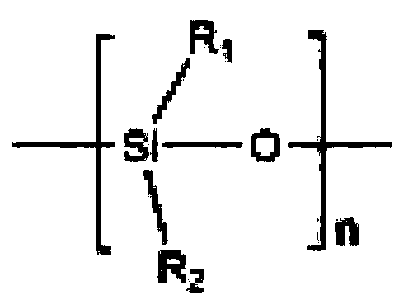

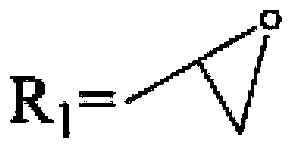

[0058] The A component includes 86.2 parts by mass of linear organosili...

Embodiment 2

[0078] A kind of epoxy resin adhesive formula that is used for rubber material bonding of the present invention, comprises A component, B component and hydrophilic silica, the quality of described A component, B component and hydrophilic silica The ratio is 100:40-55:5-7, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0079] The mass ratio of component A, component B and hydrophilic silica in this example is 100:45:7.

[0080] The viscosity of the A component is 150000cps, and the density is 1.06g / cm 3 , Epoxy value 0.33mol / 100g, it is light yellow transparent viscous liquid.

[0081] The viscosity of the B component is 7800cps, and the density is 0.95g / cm 3 , the amine value is 360mgKOH / 100g, it is light brown transparent viscous liquid.

[0082] The A component includes 82 parts by mass of linear organosilicon-modified epoxy and 18 parts by mass of hyperbranched epoxy to obtain a reactio...

Embodiment 3

[0102] A kind of epoxy resin adhesive formula that is used for rubber material bonding of the present invention, comprises A component, B component and hydrophilic silica, the quality of described A component, B component and hydrophilic silica The ratio is 100:40-55:5-7, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0103] The mass ratio of component A, component B and hydrophilic silica in this example is 100:53:5. In another embodiment it is 100:53:7.

[0104] The viscosity of the A component is 110000cps, and the density is 1.02g / cm 3 , Epoxy value 0.31mol / 100g, it is light yellow transparent viscous liquid.

[0105] The viscosity of the B component is 8300cps, and the density is 1.00g / cm 3 , amine value 400mgKOH / 100g, light brown transparent viscous liquid.

[0106] The A component includes 90 parts by mass of linear silicone-modified epoxy and 10 parts by mass of hyperbranched epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com