High-temperature slag and waste heat recovery treatment device thereof

A heat recovery device and recovery treatment technology, which is applied in the field of waste heat utilization in iron and steel smelting, can solve problems such as failure to recycle, heat waste of slag, etc., achieve good heating effect, increase waste heat utilization rate, and slow down heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

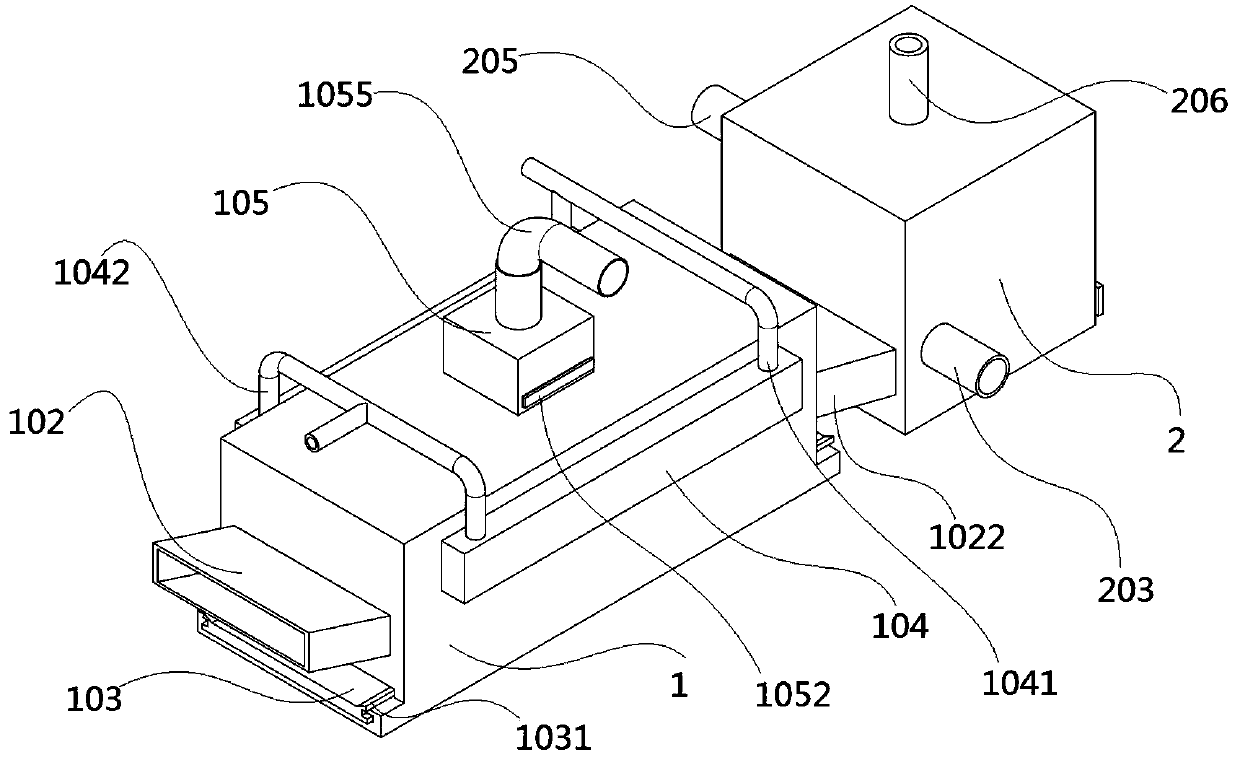

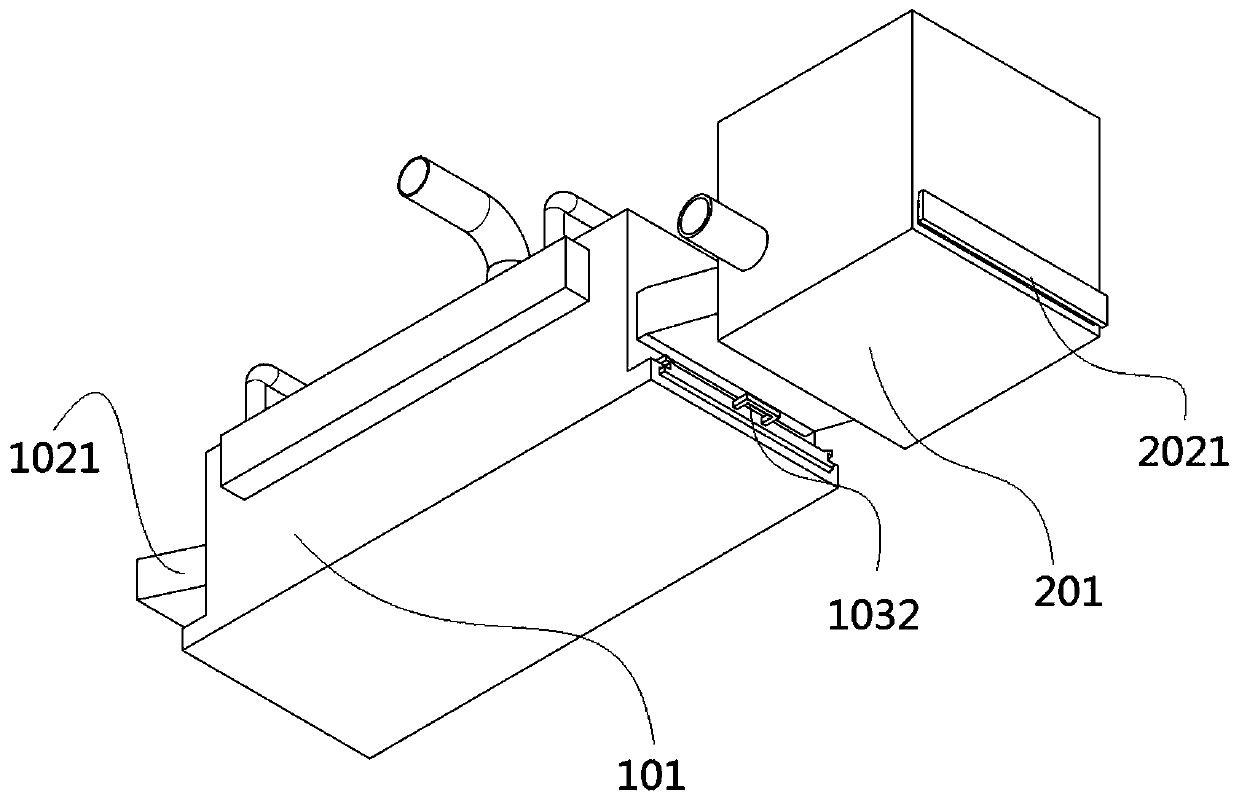

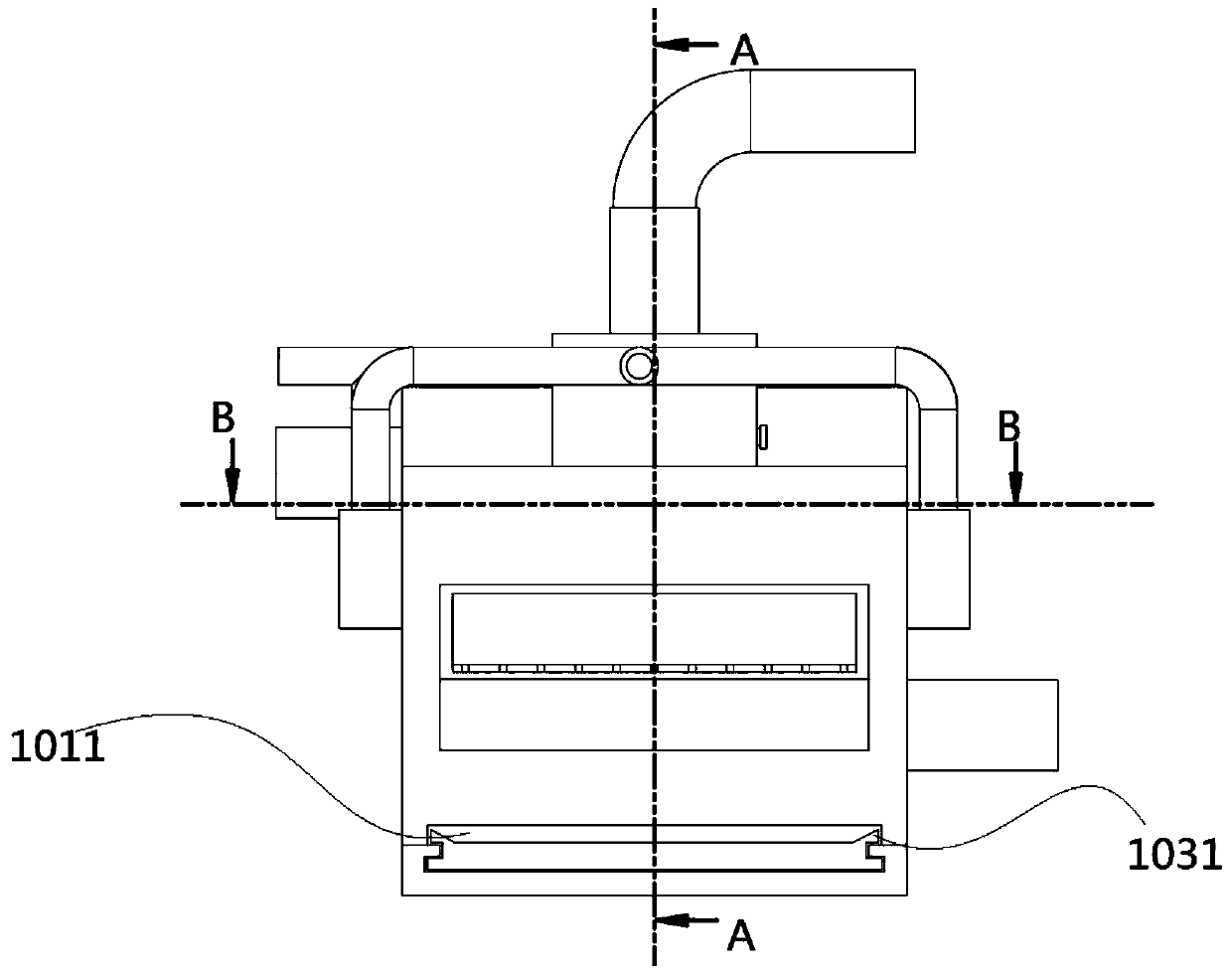

[0047] see Figure 1-6 As shown, this embodiment is a working principle and working process of a high-temperature slag and waste heat recovery treatment device:

[0048] For a high-temperature slag and waste heat recovery and processing device in the present invention, after the high-temperature slag is produced by circuit or converter smelting, in order to avoid heat waste, we send the slag into the material transfer box 101, and use the slag The high-temperature air directly emitted is passed into the smelting equipment again; at the same time, the high-temperature air also rapidly heats the water in the steam generating box 104 to generate water vapor, which is used in boiler rooms or other equipment; into the slag processing device 2, through the remaining heat, heat the cold fluid that needs to be exchanged in the tube heat pipe group; after the heat exchange is completed, it is cooled with the cooling liquid to become the final waste;

[0049] During the working process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com