HEMT type ultraviolet detector with interdigital p-GaN gate structure and preparation method of HEMT type ultraviolet detector

A technology of ultraviolet detector and grid structure, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of increasing device structure complexity and device cost, ultraviolet light loss, device photoresponsivity and other performance degradation, etc. problem, to achieve the effect of increasing the effective light-receiving area, improving the utilization rate of the sample, and increasing the optical gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing an interdigitated p-GaN gate structure HEMT type ultraviolet detector, the steps comprising:

[0037] (1) Sample cleaning: Pollutants and oxides on the surface of the sample will reduce the performance of the device, so the cleaning of the sample is also a very important link in the semiconductor process. First, put the sample into acetone to dissolve the organic pollutants on the surface of the sample, then dissolve it with alcohol to remove the remaining acetone, and finally wash off the alcohol with deionized water. Soak in diluted hydrochloric acid (the volume ratio of water and hydrochloric acid is 4:1) for 10 minutes, and finally put in acetone, alcohol and deionized water for ultrasonic cleaning, dry the moisture on the surface of the sample with a nitrogen gun, and place Bake on a baking table at 100°C for 90s to dry the remaining moisture, so as to avoid its influence on the subsequent photoresist leveling.

[0038](2) Etching of the iso...

Embodiment 2

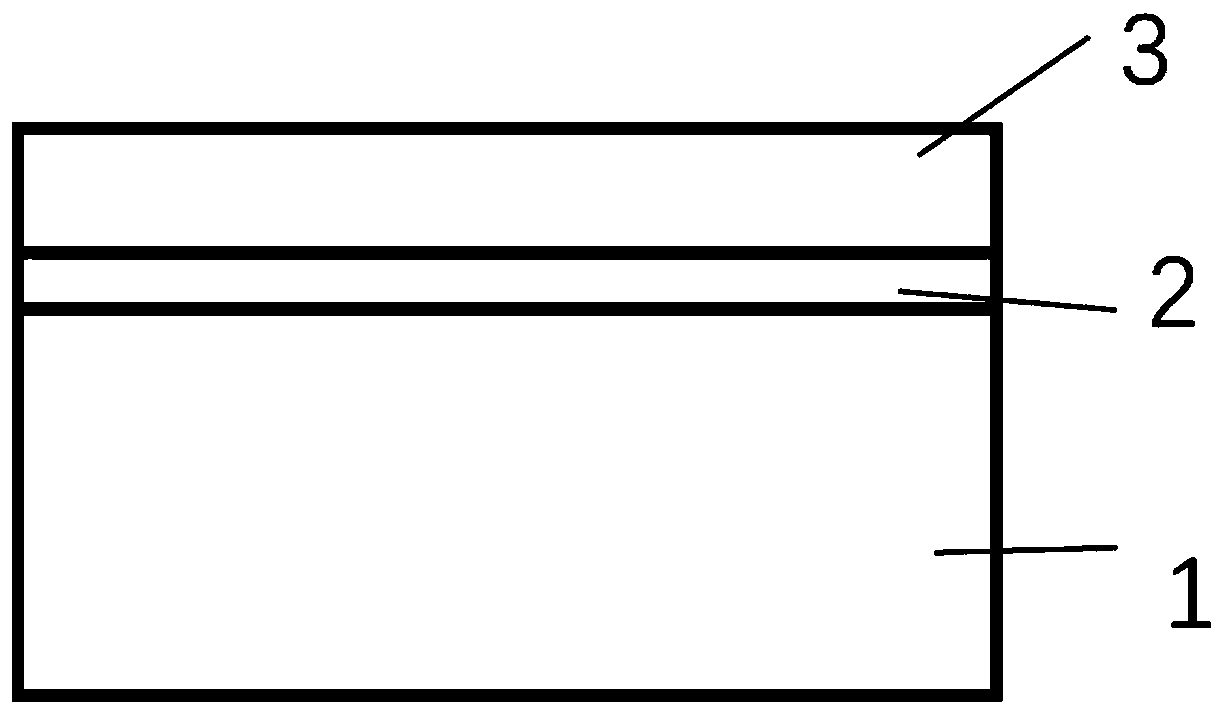

[0042] An interdigitated p-GaN gate structure HEMT type ultraviolet detector, its structure includes from bottom to top:

[0043] Sapphire substrate layer;

[0044] GaN buffer layer with a thickness of 20nm;

[0045] i-GaN layer with a thickness of 1 μm;

[0046] An unintentionally doped AlGaN layer with a thickness of 12nm and an Al composition of 20%;

[0047] p-GaN layer with a Mg doping concentration of 1×10 19 cm –3 ;

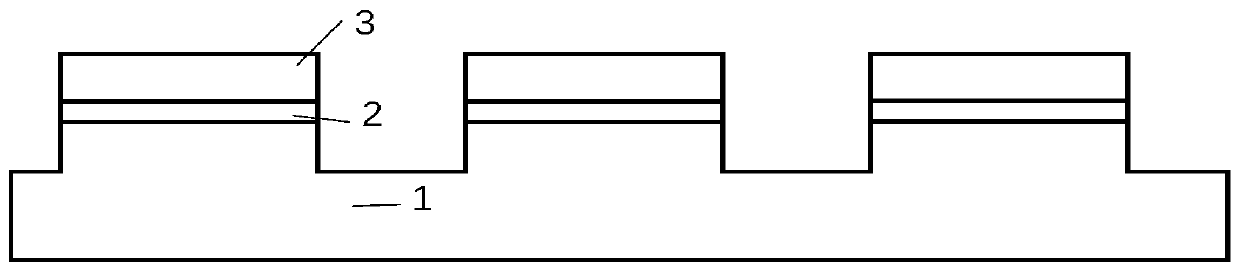

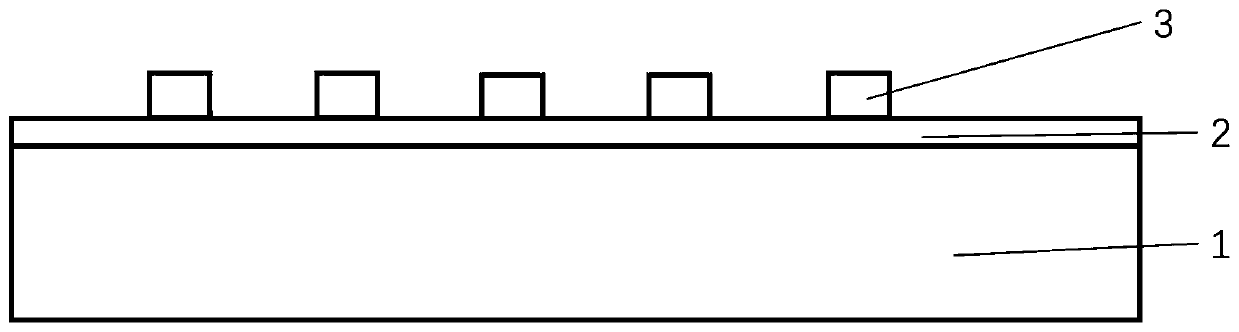

[0048] The p-GaN layer is distributed in a reciprocating zigzag pattern on the AlGaN layer, and a plurality of parallel transverse p-GaN lines are arranged on the mesa of the AlGaN layer, and all parallel p-GaN lines are connected end to end by vertical p-GaN lines , forming a complete p-GaN line, the p-GaN line divides the AlGaN layer mesa into two parts, the width of the p-GaN line is 2 μm, the thickness is 100 nm, and the distance between adjacent lateral p-GaN lines is 4μm;

[0049] It also includes an ohmic contact electrode arranged on the AlG...

Embodiment 3

[0051] An interdigitated p-GaN gate structure HEMT type ultraviolet detector, its structure includes from bottom to top:

[0052] Sapphire substrate layer;

[0053] GaN buffer layer with a thickness of 20nm;

[0054] i-GaN layer with a thickness of 2 μm;

[0055] Unintentionally doped AlGaN layer with a thickness of 14nm and an Al composition of 22%;

[0056] p-GaN layer with Mg doping concentration of 3×10 19 cm –3 ;

[0057] The p-GaN layer is distributed in a reciprocating zigzag pattern on the AlGaN layer, and a plurality of parallel transverse p-GaN lines are arranged on the mesa of the AlGaN layer, and all parallel p-GaN lines are connected end to end by vertical p-GaN lines , forming a complete p-GaN line, the p-GaN line divides the AlGaN layer mesa into two parts, the width of the p-GaN line is 1 μm, the thickness is 120 nm, and the distance between adjacent lateral p-GaN lines is 6μm;

[0058] It also includes an ohmic contact electrode arranged on the AlGaN la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com