Cubilose peptide as well as preparation method and application thereof

A bird's nest and enzymolysis technology, applied in the field of food processing, can solve the problems of enzyme flavor residue, affecting the application scope of products, complicated process, etc., and achieve the effects of improving absorption and utilization rate, avoiding bad smell, and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention discloses a preparation method of bird's nest peptide with simple preparation process and good flavor, which specifically includes the following steps:

[0049] 1) Cleaning: Soak the dried bird’s nest in medical-grade purified water at 50°C-60°C for 30-60 minutes, crush, wash, drain, add 20-60 times the amount of medical-grade purified water and simmer for 30-60 minutes until the bird’s nest is Transparent, soft waxy, no hard core state;

[0050] 2) Refining: pass the stewed bird's nest through a colloid mill for 2 to 3 times, and control the fineness of the bird's nest pulp particles within 10 μm to obtain bird's nest pulp;

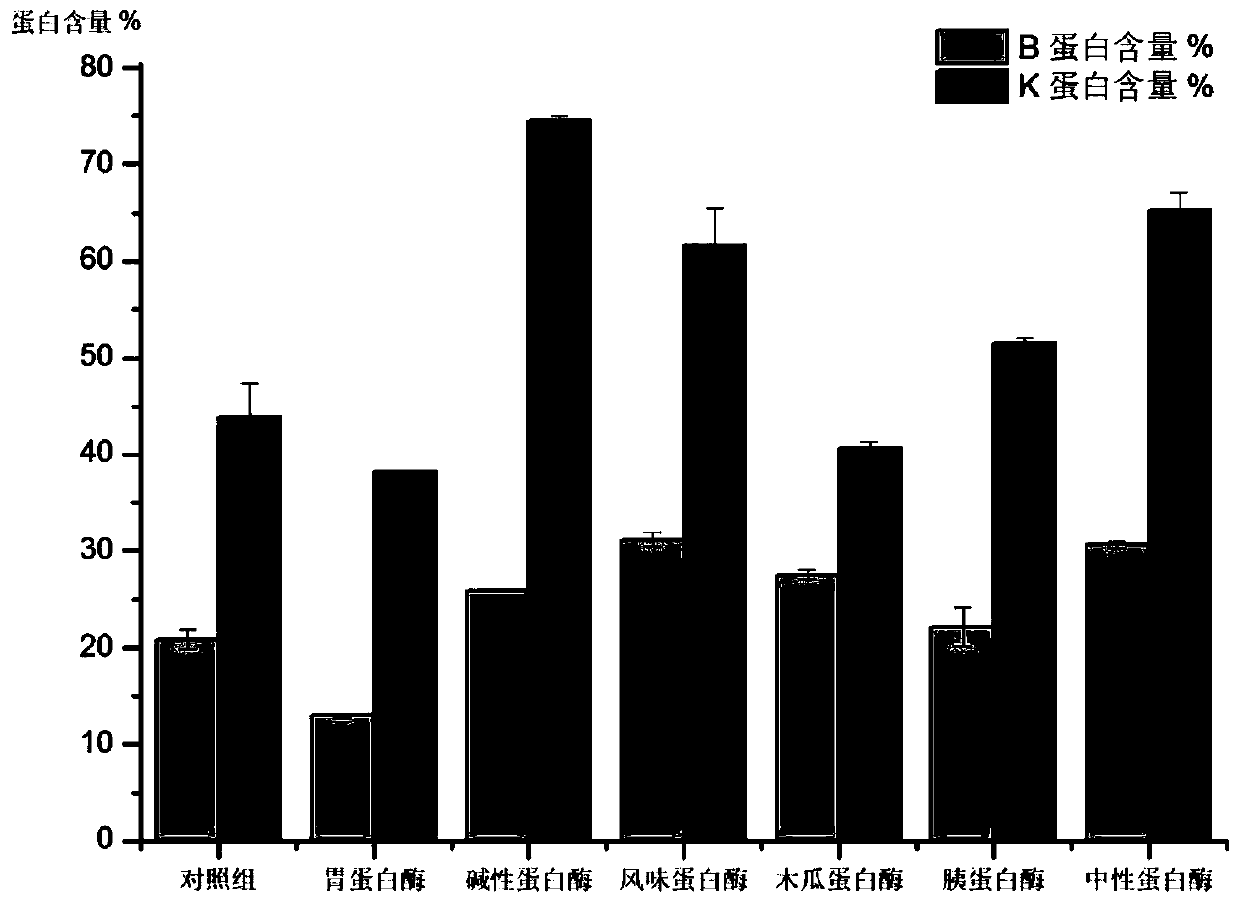

[0051] 3) The first biological enzymolysis: Pour the bird’s nest slurry into the enzymolysis tank, add purified water, the ratio of solid to liquid is (1-8): 100, and adjust the pH to 6.0-8.0, start stirring, and the speed is 30-70rpm (Keep the bird's nest pulp in a stirring state), and heat up to the tempe...

Embodiment 1

[0059] A preparation method of bird's nest peptide, comprising the following steps:

[0060] 1) Soak the dried bird’s nest in medical-grade purified water at 50°C for 40 minutes, crush, wash, drain, add 30 times the amount of medical-grade purified water and simmer for 30 minutes until the bird’s nest is transparent, soft and waxy, without hard core;

[0061] 2) passing the stewed bird's nest through a colloid mill twice to control the fineness of the bird's nest pulp particles within 10 μm to obtain bird's nest pulp;

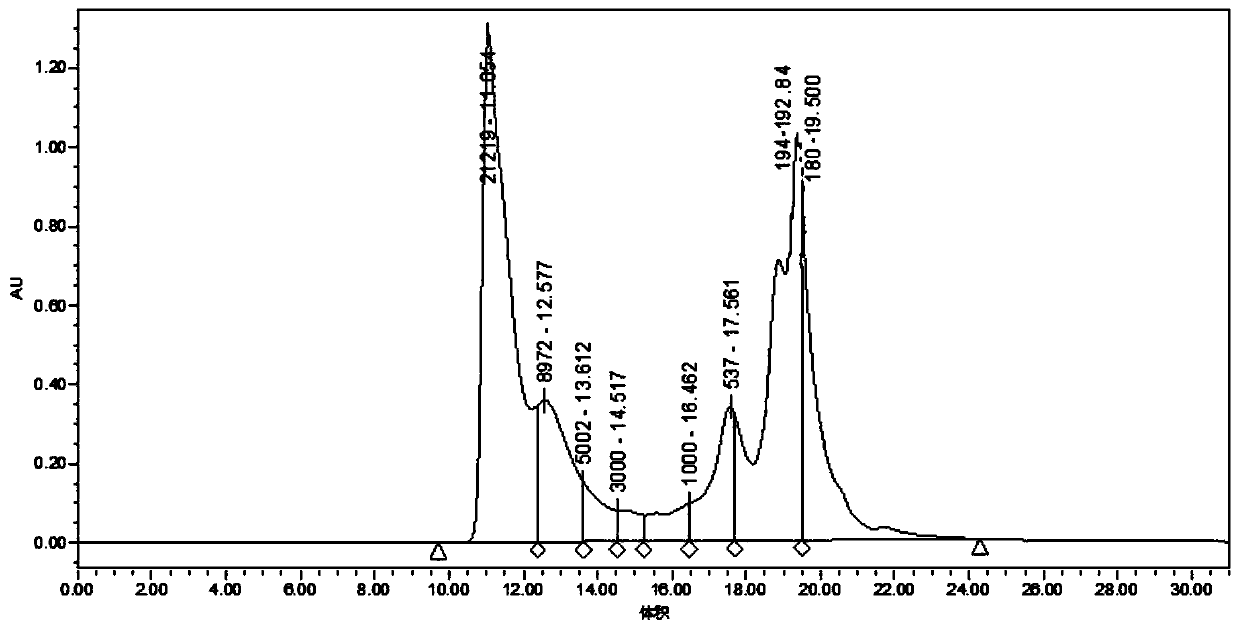

[0062] 3) Pour the bird's nest slurry into the enzymatic hydrolysis tank, add medical-grade purified water to measure the concentration of dry bird's nest to 5%, adjust the pH to 7.5, start stirring at a speed of 40rpm, and heat up to the temperature of the material in the tank to 50°C, then add Neutral protease 0.03%, carry out the first enzymatic hydrolysis, the enzymatic hydrolysis time is 40min, and the temperature of the constant temperature process is con...

Embodiment 2

[0069] A preparation method of bird's nest peptide, comprising the following steps:

[0070] 1) Soak the dried bird’s nest in medical-grade purified water at 60°C for 60 minutes, crush, wash, drain, add 40 times the amount of medical-grade purified water and simmer for 50 minutes until the bird’s nest is transparent, soft and waxy, without hard core;

[0071] 2) Pass the stewed bird's nest through a colloid mill for 3 times, and control the fineness of the bird's nest pulp particles within 10 μm to obtain the bird's nest pulp;

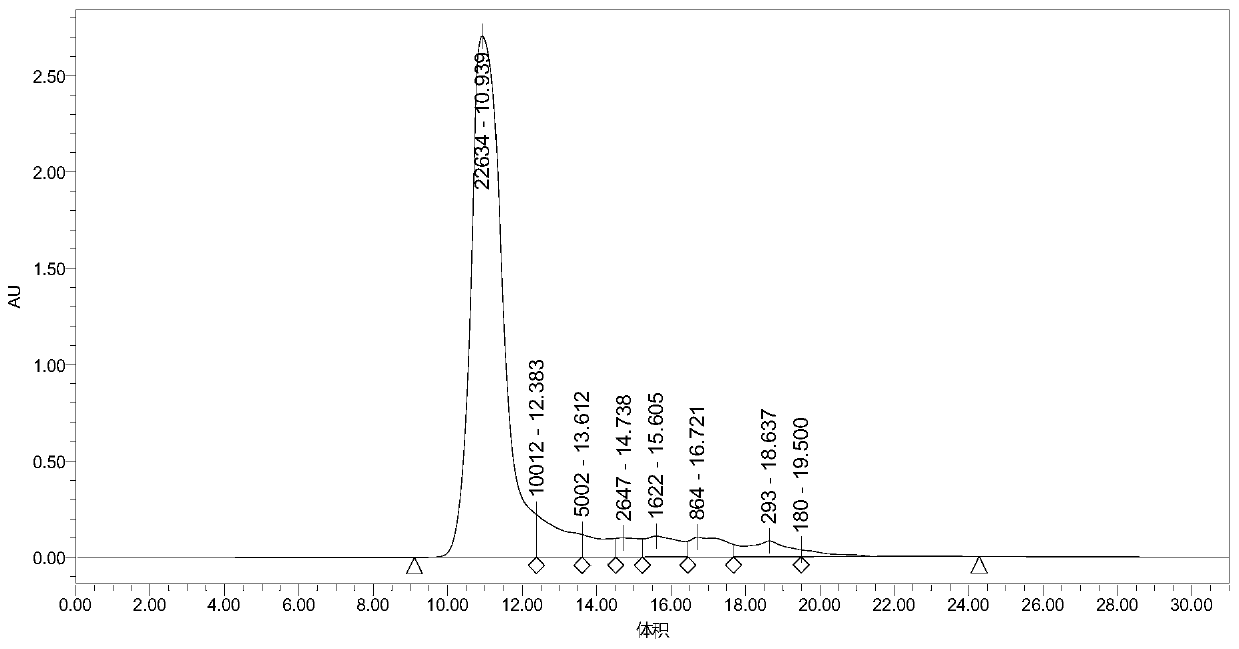

[0072] 3) Pour the bird's nest slurry into the enzymatic hydrolysis tank, add medical-grade purified water to measure the concentration of dry bird's nest to 8%, adjust the pH to 7.0, start stirring at a speed of 50rpm, and heat up to the temperature of the material in the tank to 60°C, then add Neutral protease 0.07%, carry out the first enzymatic hydrolysis, the enzymatic hydrolysis time is 50min, and the temperature of the constant temperature proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com