A composite multi-bed visible light mercury removal device and method

A visible light and mercury removal technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of increasing dust collector load and high price, and achieve good benefits, reduce mercury concentration, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

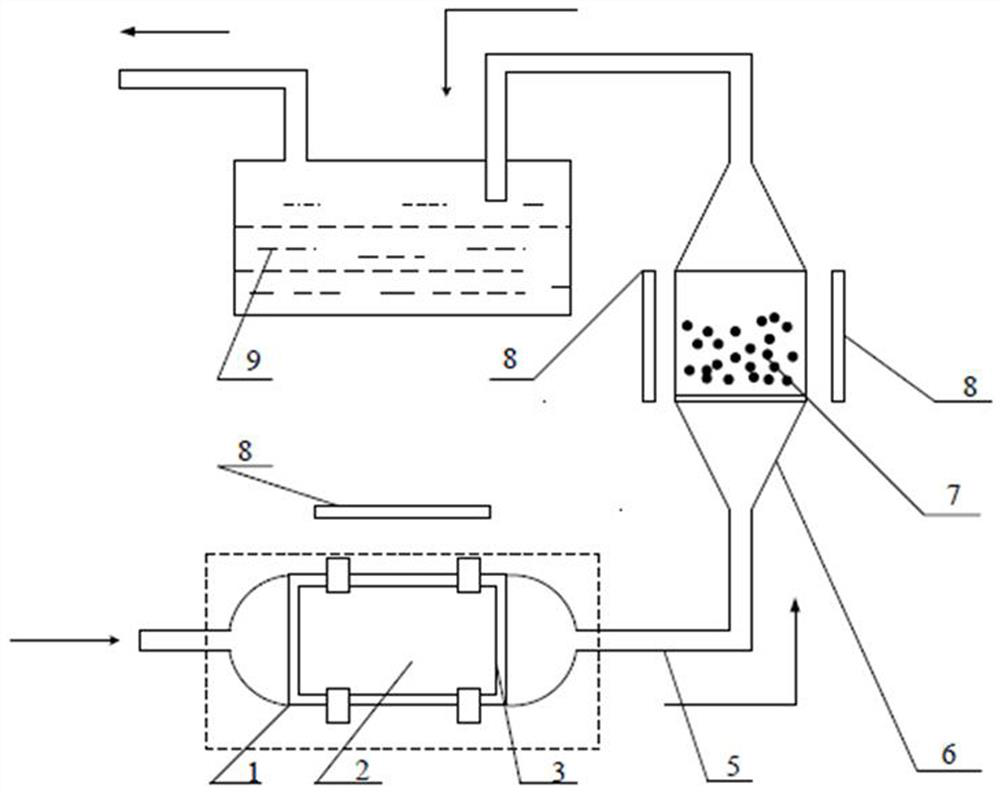

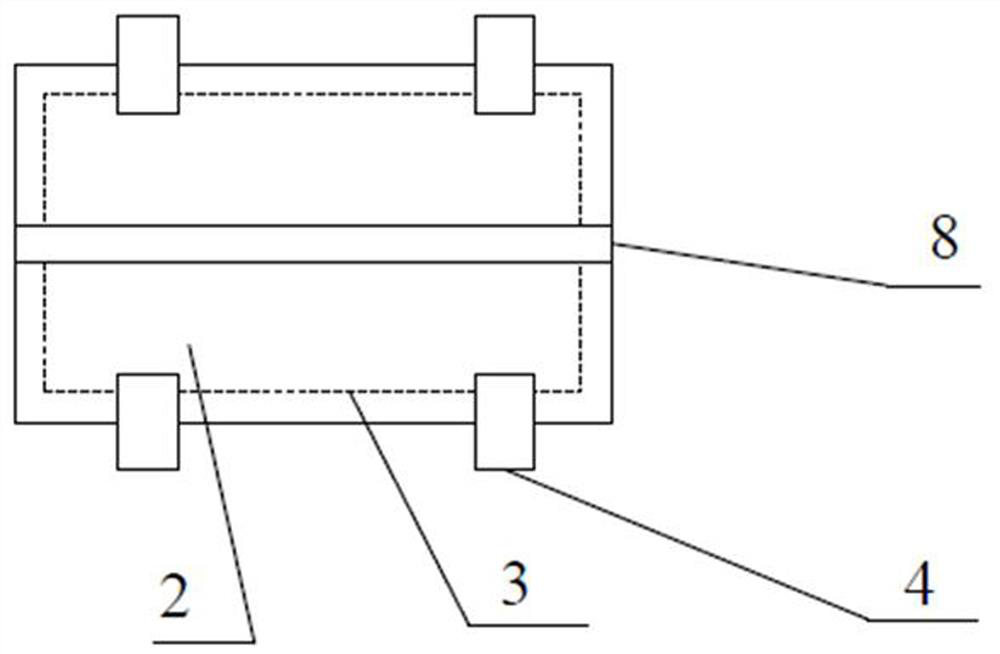

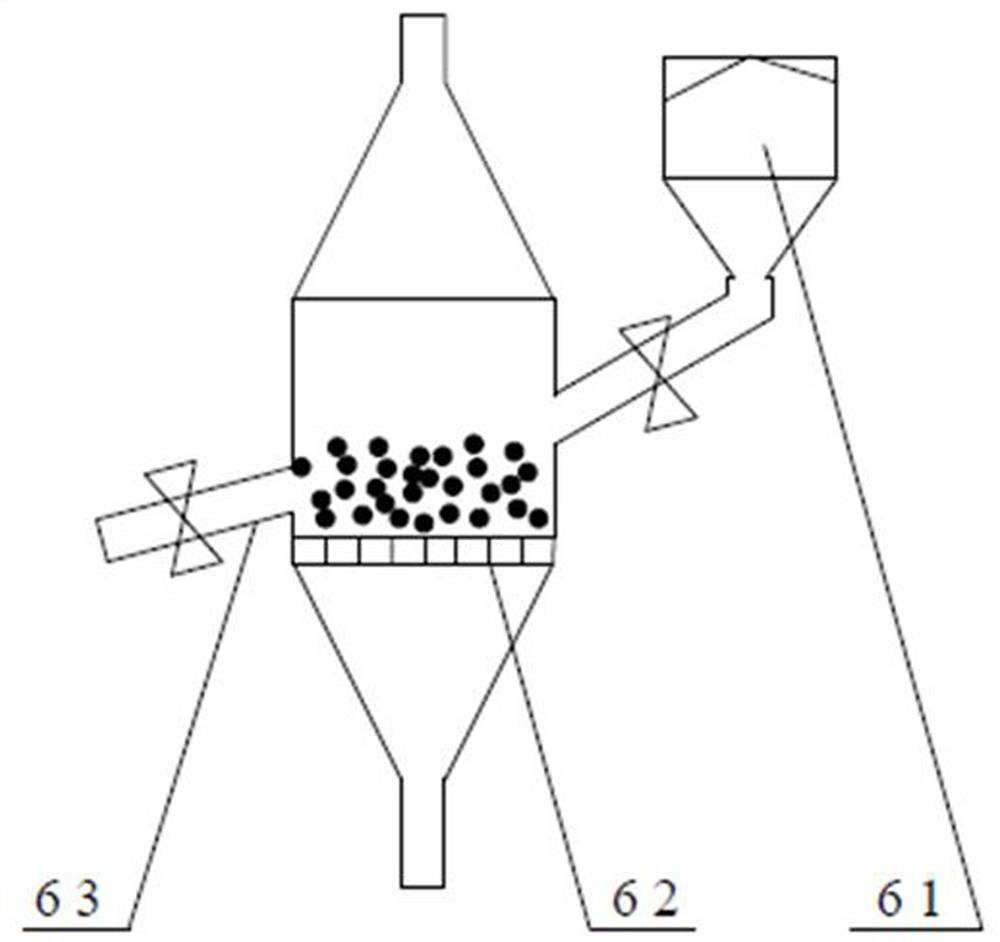

[0030] like figure 1 As shown, a compound multi-bed visible light mercury removal device includes a plexiglass fixed bed 1, a bubbling bed 6, and a mercury recovery pool 9, wherein, as shown in the figure figure 2 As shown, a catalyst carrier 2 is placed in the plexiglass fixed bed 1, and the catalyst carrier 2 is sealed in the plexiglass fixed bed 1 with quartz glass 3 through a sealing clip 4, and the catalyst carrier 2 is covered with an appropriate amount of catalyst, such as Ag- AgI-Bi 5 O 7 Br; the plexiglass fixed bed 1 is connected to the bubbling bed 6 through the pipeline 5, and the bubbling bed 6 includes a silo 61, a cloth sealing plate 62, and a discharge port 63, such as image 3 As shown, there are catalyst particles 7 in the bubbling bed 6; In this embodiment, fluorescent lamps 8 are arranged around the plexiglass fixed bed 1 and the bubbling bed 6 . In this embodiment, a fan is provided on the pipeline 5 for entering the flue gas into the mercury removing...

Embodiment 2

[0033] The method that adopts the composite multi-bed visible light mercury removal device of embodiment 1 to remove mercury in flue gas comprises the following steps:

[0034] Step (1), cover the catalyst carrier 2 with an appropriate amount of catalyst Ag-AgI-Bi 5 O 7 Br, put it into the plexiglass fixed bed 1, then cover the quartz glass 3, fix it with four sealing clips 4 and press it tightly without air leakage, turn on the fluorescent lamp 8, and radiate the catalyst carrier;

[0035] Step (2), enter the catalyst particles 7 into the bubbling bed 6 through the silo 61, and turn on the fluorescent lamp 8 to radiate it;

[0036] In step (3), the flue gas enters the plexiglass fixed bed 1 and reacts with the catalyst put into it after being pressurized by the booster fan through the pipeline 5, and the reacted gas enters the bubbling bed 6 and the catalyst particles 7 through the pipeline 5. Continue the reaction, the gas that reacts completely enters the mercury recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com