Iron-manganese-magnesium-loading layered hydroxide composite semicoke and preparation method thereof

A hydroxide and semi-coke technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as large head loss, small particles, affecting the effect of phosphorus removal from wastewater, and achieve low cost. , The effect of overcoming difficult recovery and high-efficiency adsorption and removal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

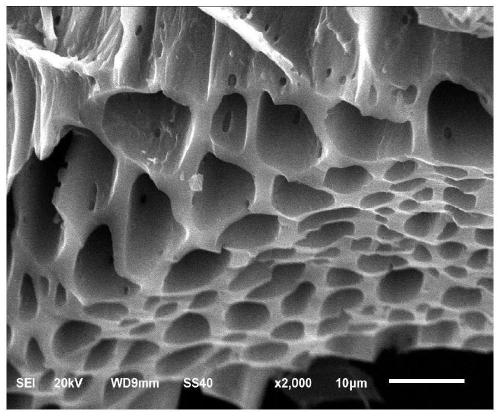

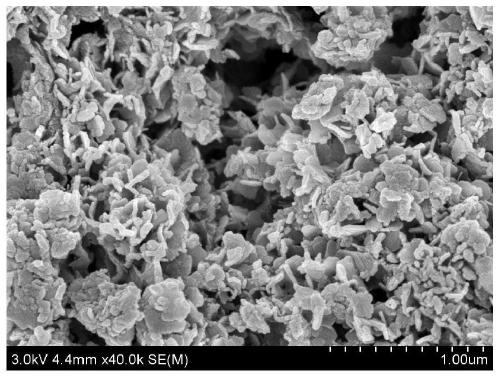

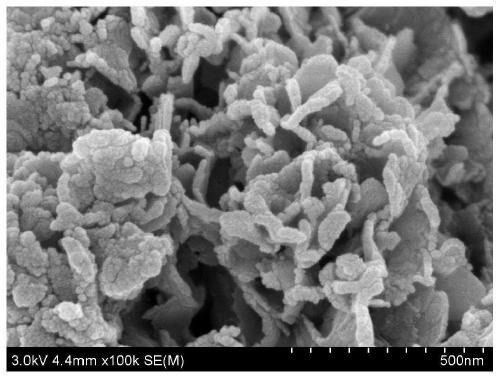

[0023] see Figure 1-3 , a layered hydroxide composite semi-coke loaded with iron, manganese and magnesium, including biomass pyrolysis semi-coke with internal pores and electron binding characteristics, and the inner and outer surfaces of biomass pyrolysis semi-coke are immobilized with layered structure Layered hydroxides of iron, manganese and magnesium.

[0024] In this example, the pore diameter of the biomass pyrolysis semi-coke is 10-500nm, and the biomass pyrolysis semi-coke with good pore distribution and huge specific surface area is used as a carrier, and the Fe 3+ , Mn 2+ , Mg 2+ The ions are introduced into the inner and outer surfaces of the biomass pyrolysis semi-coke through ion diffusion; then through the co-precipitation reaction, the Fe 3+ , Mn 2+ , Mg 2+ Ions precipitate on the inner and outer surfaces of biomass pyrolysis semi-coke to form layered hydroxides of iron, manganese and magnesium with a lamellar structure, and the size of the layered hydrox...

Embodiment 2

[0027] A method for preparing iron-manganese-magnesium layered hydroxide composite semi-coke, comprising the following steps:

[0028] S1. Add 2-10 g of biomass pyrolysis semi-coke into 50-150 ml of water, and add 5-15 ml of ethanol into it at the same time, stir for 20-40 min, and filter and wash to obtain sample 1;

[0029] S2. Configure 150-200ml containing FeCl 3 , MnCl 2 , MgCl 2 The mixed solution, FeCl in the mixed solution 3 , MnCl 2 , MgCl 2 The concentration of the total substance is 2mol / L, and 15-25ml of hydrochloric acid with a mass fraction of 37% is added to the mixed solution, 2-10g of sample 1 is added to the mixed solution, stirred for 2-6h, and mixed sample 2 is obtained The addition of hydrochloric acid can keep the mixed solution in an acidic state during the stirring process, preventing the occurrence of hydroxide precipitation in the mixed solution, which is beneficial to Fe 3+ , Mn 2+ , Mg 2+ The ions are evenly dispersed in the mixed solution. ...

Embodiment 3

[0032] A method for preparing iron-manganese-magnesium layered hydroxide composite semi-coke, comprising the following steps:

[0033] S1. Take 5 g of biomass pyrolysis semi-coke with good pore distribution and stable skeleton into a three-necked flask, add 10 ml of ethanol and 100 ml of water, stir for 30 min, and repeat suction filtration and washing 3 times to obtain sample 1.

[0034] S2, transfer gained sample 1 in the three-neck flask, add the concentrated hydrochloric acid of 10ml 37%, 190ml FeCl 3 / MnCl 2 / MgCl 2 mixed solution, where FeCl 3 : MnCl 2 : MgCl 2 The ratio of the amount of the substance is 1:1:2, stirred for 4h, and mixed sample 2 was obtained;

[0035]S3. Under the protection of nitrogen atmosphere, under the condition of continuous stirring, add 2mol / L NaOH dropwise to the prepared mixed sample 2, adjust the pH value to 10, continue stirring for 2h after the dropwise addition, suction filtration, washing, and then Freeze-drying at -40°C and 40Pa fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com