Composite flexible pressure sensor based on bionic microstructure and preparation method of composite flexible pressure sensor

A pressure sensor and microstructure technology, applied in the field of flexible electronics and sensors, can solve the problems of reducing the integration of flexible pressure sensors, limiting the development of flexible pressure sensors, and not being able to collect multi-source signals at the same time, so as to improve signal acquisition performance and increase pressure. The effect of improving the detection range and detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

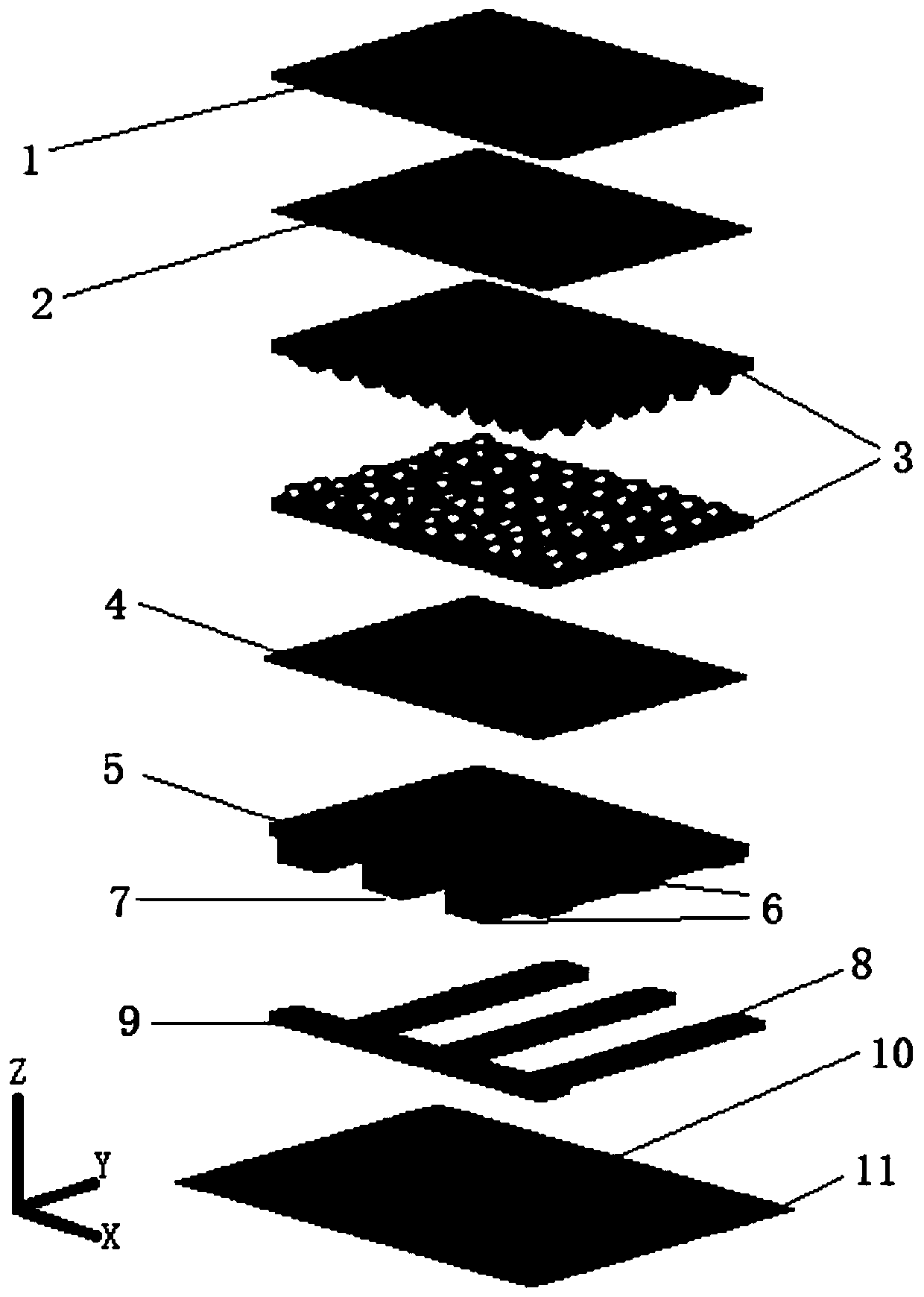

[0055] The preparation method of the compound flexible pressure sensor based on the bionic microstructure of the present invention specifically includes:

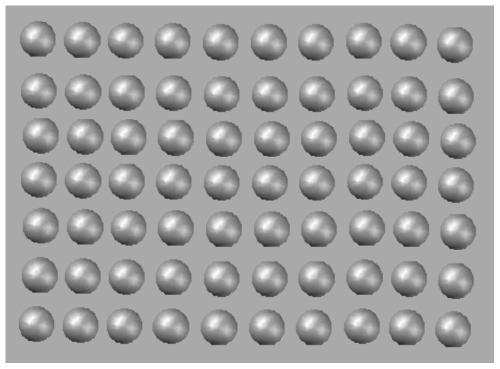

[0056] Step 1: Put the PDMS solution in which the prepolymer and the curing agent are fully mixed at a ratio of 10:1 into a vacuum desiccator, which can remove the bubbles generated inside the PDMS mixture during the stirring process. Then the PDMS mixture was spin-coated on the surface of the anti-mold of the single-layer double-stage dome biomimetic microstructure, the forward rotation speed was 1000r / min for 45s and the back rotation speed was 5000r / min for 50s;

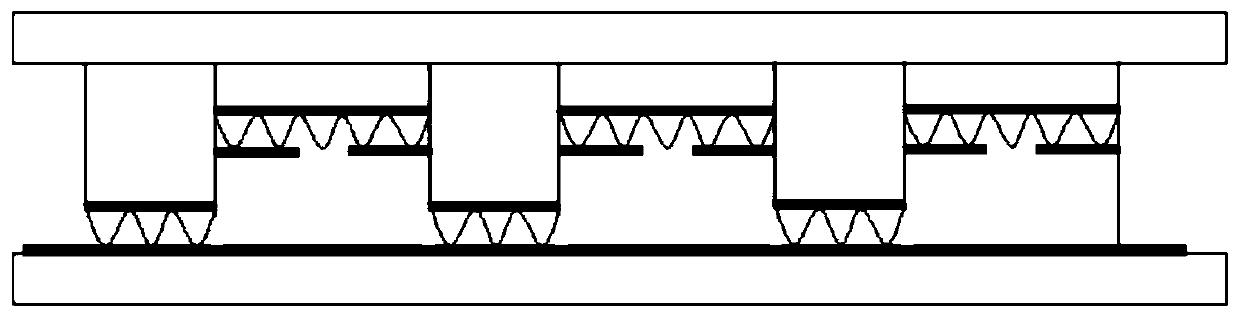

[0057] Step 2: The PDMS solution is cured at 100°C for 50 minutes, and the PDMS film is obtained after peeling off. Please refer to the attached figure 1 One side of the dielectric layer 3 shown in , the thickness of which is about 60 μm;

[0058] Step 2: The PDMS solution was cured at 100°C for 50 minutes, and the PDMS film was obtained after peeling off. Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average height | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com