A kind of gliadin-phenolic antioxidant nanoparticle and Pickering emulsion prepared therefrom

A technology of Pickering emulsion and gliadin, which is applied in the field of Pickering emulsion preparation, can solve the problems of complex anti-oil oxidation stability and poor physical stability, etc., and achieve improved anti-oxidation efficiency, high yield, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 Preparation of a Zein-Gallic Acid Composite Nanoparticle

[0067] (1) 1 g of zein powder and 3 mmol of gallic acid were dissolved in 40 mL of 70% (v / v) ethanol aqueous solution under the conditions of 60 W ultrasonic and 600 rpm stirring to obtain a zein-gallic acid ethanol solution;

[0068] (2) Add the mixed zein-gallic acid ethanol solution dropwise to 120 mL of Tween 20 aqueous solution containing 0.05 g under the condition of 200 rpm magnetic stirring to obtain the dispersed zein-gallic acid composite nanoparticles liquid;

[0069] (3) Subsequently, the nanoparticle dispersion liquid was rotary evaporated and concentrated to a volume of 50 mL, and the ethanol was removed to obtain a zein-gallic acid composite nanoparticle solution.

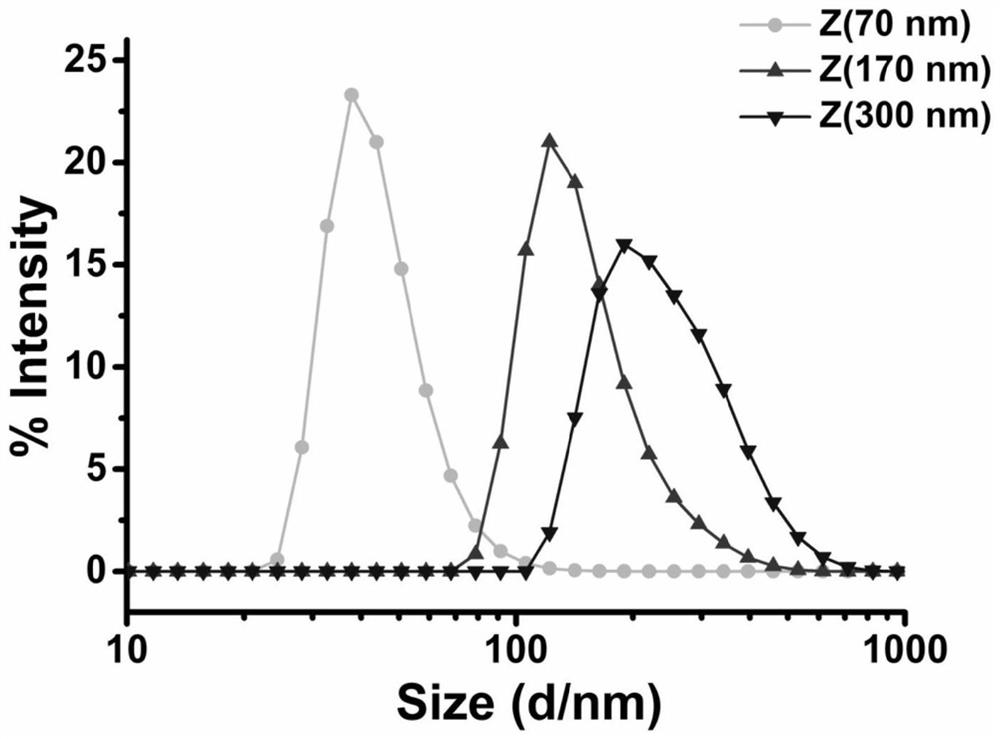

[0070] The average particle diameter of the zein-gallic acid composite nanoparticles prepared in this example is 70 nm. Such as figure 1 shown.

Embodiment 2

[0071] Example 2 Preparation of a Zein-Gallic Acid Composite Nanoparticle

[0072] (1) 1 g of zein powder and 3 mmol of gallic acid were dissolved in 25 mL of 90% (v / v) aqueous ethanol under conditions of 50 W ultrasound and 600 rpm stirring to obtain a zein-gallic acid ethanol solution;

[0073] (2) Add the mixed zein-gallic acid ethanol solution dropwise to 80 mL of Tween 20 aqueous solution containing 0.05 g under the condition of 200 rpm magnetic stirring to obtain the dispersed zein-gallic acid composite nanoparticles liquid;

[0074] (3) Subsequently, the nanoparticle dispersion liquid was rotary evaporated and concentrated to a volume of 50 mL, and the ethanol was removed to obtain a zein-gallic acid composite nanoparticle solution.

[0075] The average particle diameter of the zein-gallic acid composite nanoparticles prepared in this example is 170 nm. Such as figure 1 shown.

Embodiment 3

[0076] Example 3 Preparation of a Zein-Gallic Acid Composite Nanoparticle

[0077] (1) 1 g of zein powder and 3 mmol of gallic acid were dissolved in 15 mL of 90% (v / v) aqueous ethanol under conditions of 50 W ultrasound and 600 rpm stirring to obtain a zein-gallic acid ethanol solution;

[0078] (2) Add the mixed zein-gallic acid ethanol solution dropwise to 65 mL of Tween 20 aqueous solution containing 0.05 g under the condition of 200 rpm magnetic stirring to obtain zein-gallic acid composite nanoparticle dispersion liquid;

[0079] (3) Subsequently, the nanoparticle dispersion liquid was rotary evaporated and concentrated to a volume of 50 mL, and the ethanol was removed to obtain a zein-gallic acid composite nanoparticle solution.

[0080] The average particle diameter of the zein-gallic acid composite nanoparticles prepared in this example is 300 nm. Such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com