Anti-corrosion and heat-dissipation integrated coating of waterborne graphene/epoxy zinc-rich dispersion system and preparation method and application thereof

A water-based epoxy zinc-rich, water-based graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc. Low, low corrosion resistance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

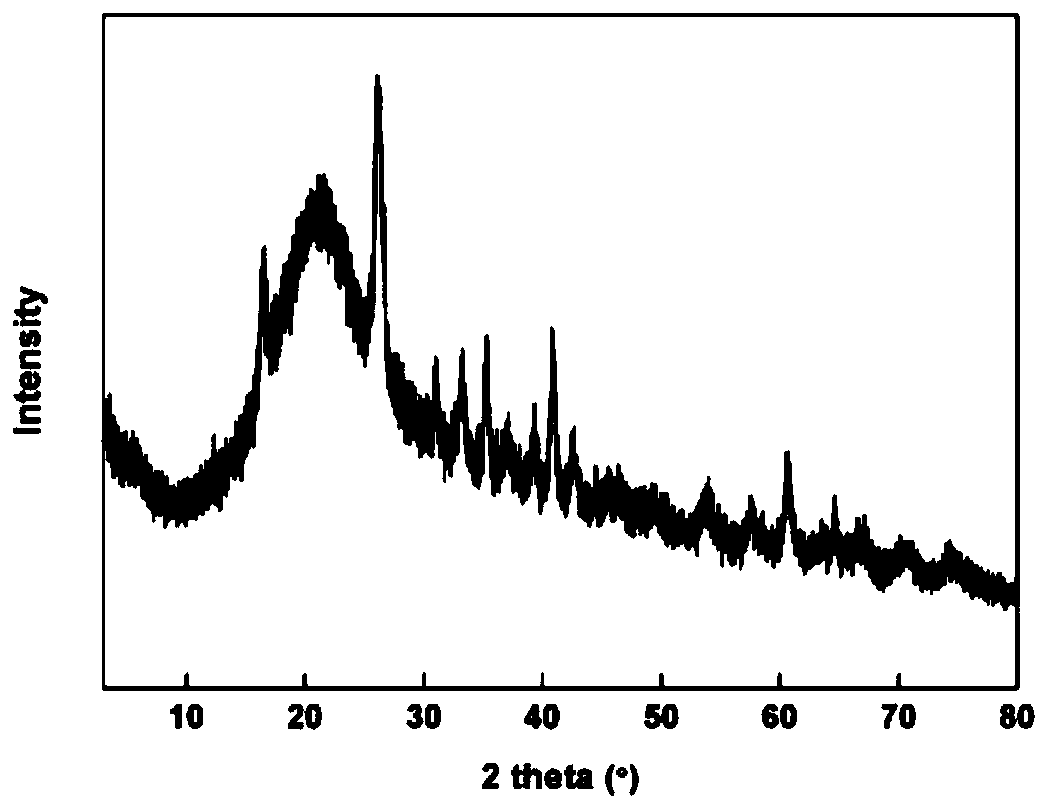

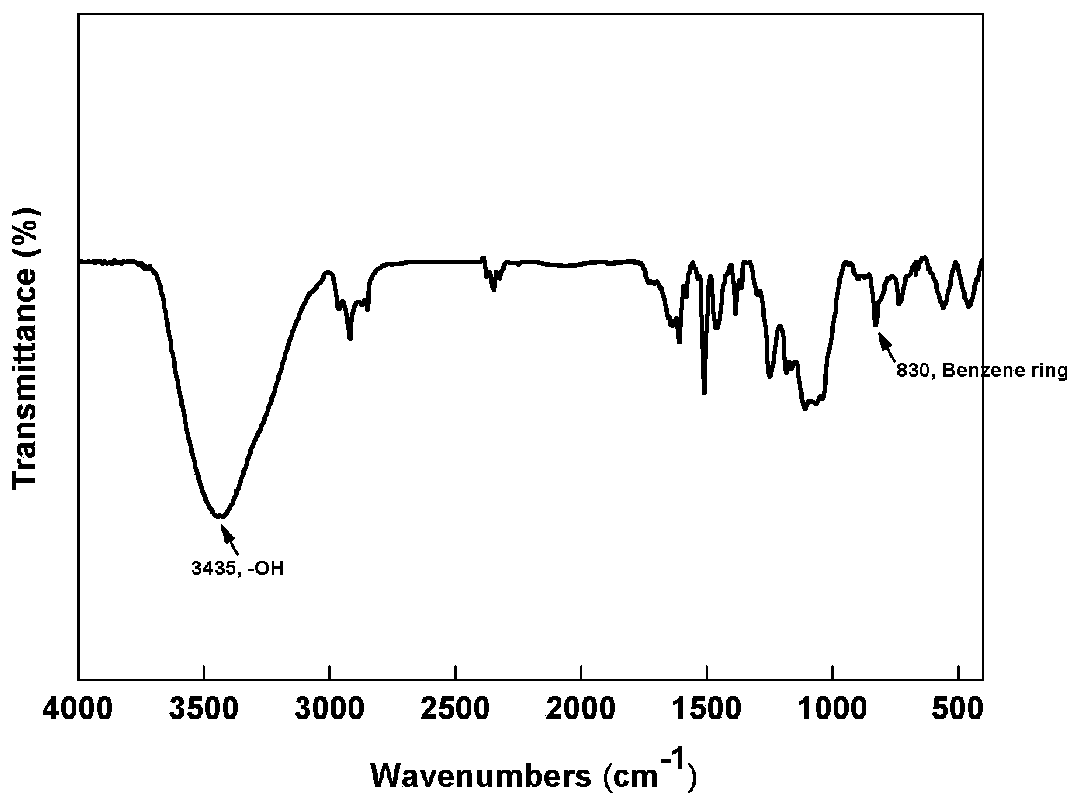

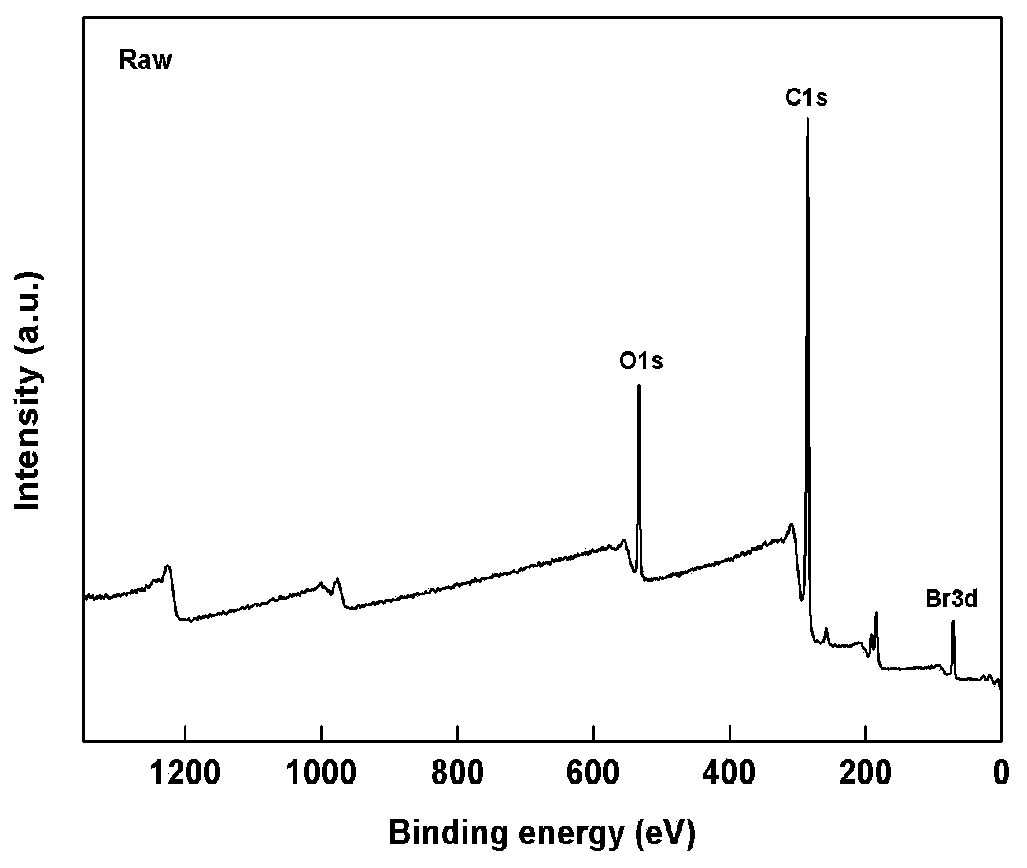

Image

Examples

preparation example Construction

[0053] The present invention also provides the preparation method of the anticorrosion and heat dissipation integrated coating of the water-based graphene / epoxy zinc-rich dispersion system described in the above technical solution, comprising the following steps:

[0054] After mixing hydrophilic graphene, hydrophilic kaolin, water and water-based epoxy zinc-rich resin, a doped resin is obtained;

[0055] Mix the doped resin, fumed silica, defoamer, leveling agent and two-component water-based epoxy zinc-rich curing agent to obtain the integrated anti-corrosion and heat dissipation of the water-based graphene / epoxy zinc-rich dispersion system coating.

[0056] The invention mixes hydrophilic graphene, hydrophilic kaolin, water and water-based epoxy zinc-rich resin to obtain doped resin.

[0057] In the present invention, the mixing method is preferably magnetic stirring. In the present invention, there is no special limitation on the rotational speed and time of the magnetic ...

Embodiment 1

[0071] Weigh 1g of graphene in a beaker, then weigh 1g of sodium lauryl sulfate, 0.5g of tetrabutylammonium bromide, 3g of polyvinyl alcohol and 45mL of distilled water for magnetic stirring to obtain hydrophilic graphene;

[0072] Weigh 2g of calcined kaolin (calcined under oxygen, the calcination temperature is 400°C, and the calcination time is 6h) in a beaker, then weigh 1g sodium lauryl sulfate, 0.5g tetrabutylammonium bromide, 3g polyethylene Alcohol and 45mL distilled water are magnetically stirred to obtain hydrophilic kaolin;

[0073] Weigh 15g of water-based epoxy zinc-rich resin, 1g of hydrophilic graphene, 1g of hydrophilic kaolin and 3ml of water in a beaker, stir evenly, weigh 0.1g of fumed silica, add it to the beaker, stir evenly, and then measure Take 2ml of tributyl phosphate, 1ml of leveling agent, two-component water-based epoxy zinc-rich curing agent, and stir for 2 hours with a DW-2 booster stepless constant speed mixer until the dispersion is uniform to ...

Embodiment 2

[0079] The difference between this example and Example 1 is that the calcined kaolin used is at a calcination temperature of 600° C. and a calcination time of 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com