Preparation method of high-concentration mixed coal water slurry additive

A technology for preparing additives and mixing water, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of increasing the difficulty of making coal-water slurry, high efficiency and high price, and poor performance at low cost, so as to promote the surface tension of coal Decrease, good stability and dispersibility, enhance the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a high-concentration mixed coal-water slurry additive, comprising the following steps:

[0024] Step 1: Weigh 60g of potassium lignosulfonate, 10g of polyethyleneimine and 1g of ammonium chloride, add 100ml of water, and react at 40±5°C for 1h;

[0025] Step 2: After the first step of reaction, cool down to 30±5°C, add 6g of aniline and stir for 0.5h, add 30g of polyethylene glycol 200 to react for 2h, the reaction is completed, and component A is obtained;

[0026] Step 3: Weigh 10g of β-naphthalenesulfonate sodium formaldehyde condensation product into the reactor, add 3g of pyridine and 100ml of water, then dropwise add 10g of triethanolamine dodecylsulfate, and react at 30°C for 2h to obtain the component B;

[0027] Step 4: Mix component A and component B, adjust the pH to 7-8 with 10% sodium hydroxide, concentrate under reduced pressure, and freeze-dry to obtain solid powder of the additive.

Embodiment 2

[0029] A method for preparing a high-concentration mixed coal-water slurry additive, comprising the following steps:

[0030] Step 1: Weigh 70g of sodium lignosulfonate, 15g of polyethyleneimine by weight and 2g of ammonium chloride, add 150ml of water, and react at 40±5°C for 2 hours;

[0031] Step 2: After the first reaction, cool down to 35±5°C, add 7g of aniline and stir for 0.8h, add 35g of polyethylene glycol 600 and react for 2.5h, the reaction is completed, and component A is obtained;

[0032] Step 3: Weigh 15g of β-naphthalenesulfonate sodium formaldehyde condensation product into the reactor, add 4g of pyridine and 100ml of water, then dropwise add 12g of triethanolamine dodecylsulfate, and react at 45±5°C for 3h to obtain the compound share B;

[0033] Step 4: Mix component A and component B, adjust the pH to 7-8 with ammonia water, concentrate under reduced pressure, and freeze-dry to obtain solid powder of the additive.

Embodiment 3

[0035] A method for preparing a high-concentration mixed coal-water slurry additive, comprising the following steps:

[0036] Step 1: Weigh 80g of sodium lignosulfonate, 20g of polyethyleneimine and 3g of ammonium chloride, add 200ml of water, and react at 50°C for 3h;

[0037] Step 2: After the first step of reaction, cool down to 40°C, add 8g of aniline and stir for 1 hour, add 40g of polyethylene glycol 1000 for reaction for 3 hours, and the reaction is completed to obtain component A;

[0038] Step 3: Weigh 20g of α-naphthalenesulfonate sodium formaldehyde condensation product into the reactor, add 5g of pyridine and 150ml of water, then dropwise add 15g of triethanolamine dodecylsulfate, and react at 60°C for 4h to obtain component B ;

[0039] Step 4: Mix component A and component B, adjust the pH to 7-8 with 10% potassium hydroxide, concentrate under reduced pressure, and freeze-dry to obtain solid powder of the additive.

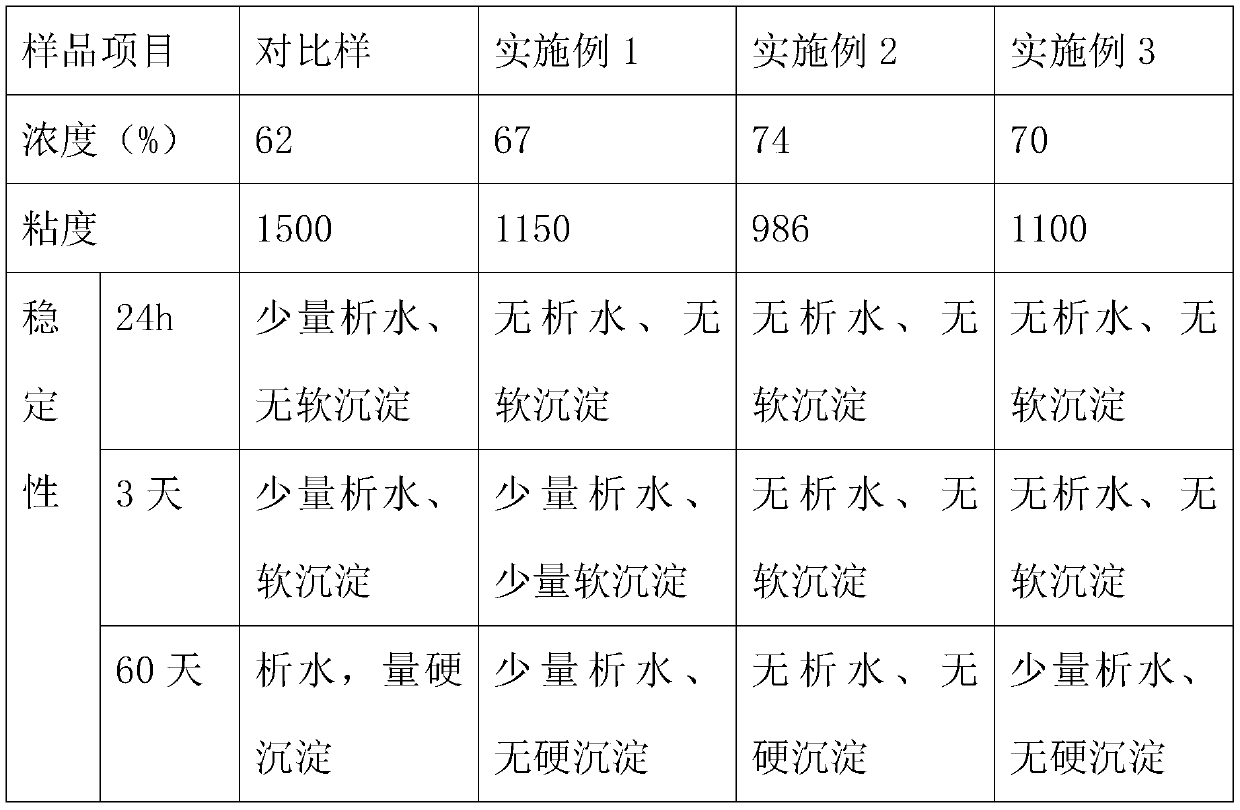

[0040] In addition, commercially available s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com