Non-woven fabric material and application thereof

A technology of non-woven fabrics and reaction temperature, applied in the direction of non-woven fabrics, textiles and papermaking, cellulose/protein conjugated artificial filaments, etc. Anti-cross-color effect and other issues to achieve the effect of ensuring the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] One, the preparation of modified cellulose A

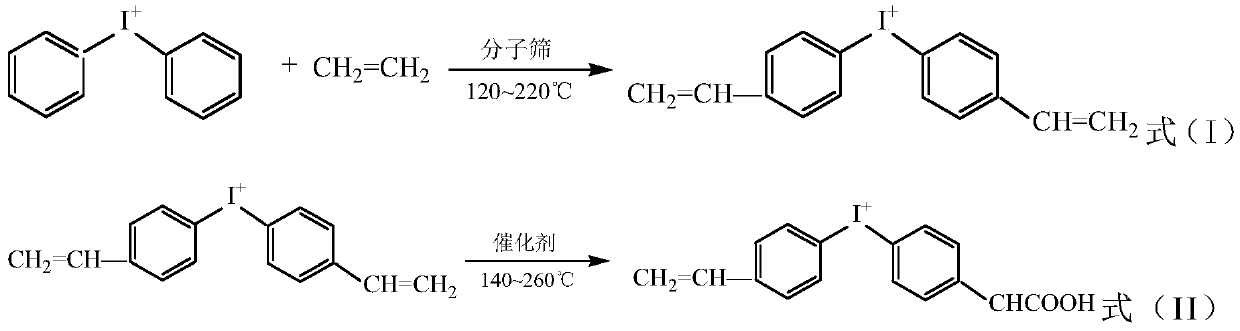

[0040] One), the preparation of (4-vinylphenyl-4'-methylenecarboxyphenyl) iodonium

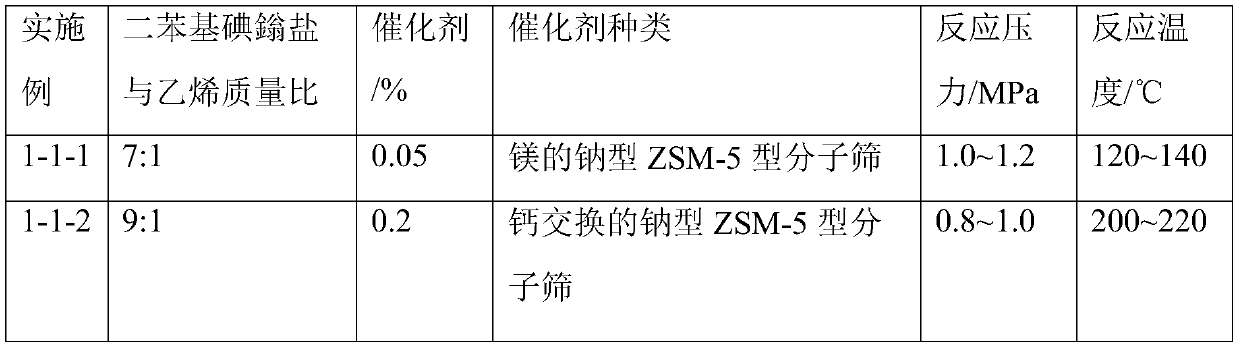

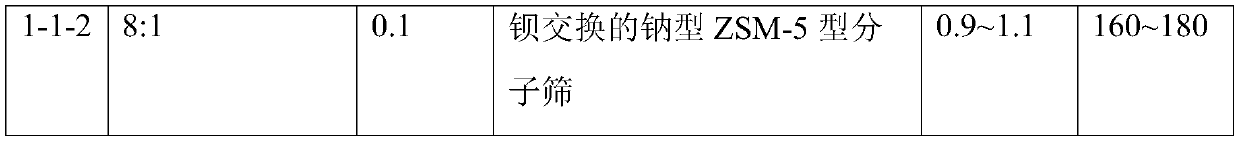

[0041] 1. Using molecular sieves as a catalyst, diphenyliodonium salt reacts with ethylene to obtain 4,4'-divinyldiphenyliodonium (as shown in formula (I)) (embodiment 1-1-1, 1 The reaction conditions of -1-2 and 1-1-3 are shown in Table 1), 4,4'-divinyldiphenyliodonium is partially oxidized through the supported palladium (Pd) heteropolyacid catalyst system Obtain 4-vinylphenyl-4'-methylenecarboxyphenyl) iodonium (as shown in formula (II)) (embodiment 1-1-1, 1-1-2, 1-1-3 reaction The conditions are shown in Table 2):

[0042]

[0043] Among them, the molecular sieve is sodium ZSM-5 molecular sieve exchanged by magnesium, calcium or barium.

[0044] Table 1 Diphenyliodonium salt and ethylene reaction conditions and substance consumption

[0045]

[0046]

[0047] Table 2 Reaction conditions and amounts of substances used in par...

Embodiment 1-2-1

[0051] 1. Synthesis of (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone

[0052] The monomer vinylpyrrolidone (NVP) is configured into an aqueous solution with a mass fraction of 45%, using a small amount of hydrogen peroxide (0.2% of NVP) as a catalyst, under the action of azobisisobutyronitrile (0.3% of NVP), in Initiate polymerization at 40-50°C, react for 2 hours, and the monomer polymerization conversion rate is 93-95%. Add (4-vinylphenyl-4'-methylenecarboxyphenyl) iodonium (amount of 0.5% NVP) prepared in Example 1-1-1, react for 0.2 hours, and seal the polymer terminal to obtain (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone.

[0053] Then add 0.2% ammonia water to the polymer to decompose the remaining azobisisobutyronitrile. The polymer is spray-dried under hot air at 120-135°C to obtain powdery (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone. (4-vinylphenyl-4'-m...

Embodiment 1-2-2

[0065] 1. Synthesis of (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone

[0066] The monomer vinylpyrrolidone (NVP) was configured into an aqueous solution with a mass fraction of 50%. Use a small amount of hydrogen peroxide (0.3% NVP) as a catalyst, under the action of azobisisobutyronitrile (0.4% NVP), initiate polymerization at 50-60°C, react for 3 hours, and the monomer polymerization conversion rate is 96~98%.Add ((4-vinylphenyl-4-methylenecarboxyphenyl) iodonium (consumption is the NVP of 0.8%) that embodiment 1-1-1 makes, reacted 0.5 hour, Capping the polymer yields (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-capped polyvinylpyrrolidone.

[0067] Add 0.3% ammonia water to the polymer to decompose the remaining azobisisobutyronitrile. The polymer is spray-dried under hot air at 135-150°C to obtain powdery (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone. (4-vinylphenyl-4'-methylenecarboxyphenyl) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com