Aqueous zinc-iodine battery based on four-electron conversion reaction and electrolyte thereof

A zinc-iodine battery and electrolyte technology, which is applied in the directions of aqueous electrolyte, secondary battery, and secondary battery repair/maintenance, can solve the problems of unsatisfactory electrochemical performance, unsatisfactory zinc-iodine battery capacity and energy density, etc. Improve the four-electron conversion reaction activity of I-/I2/I+, improve the electrochemical performance, and avoid the effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

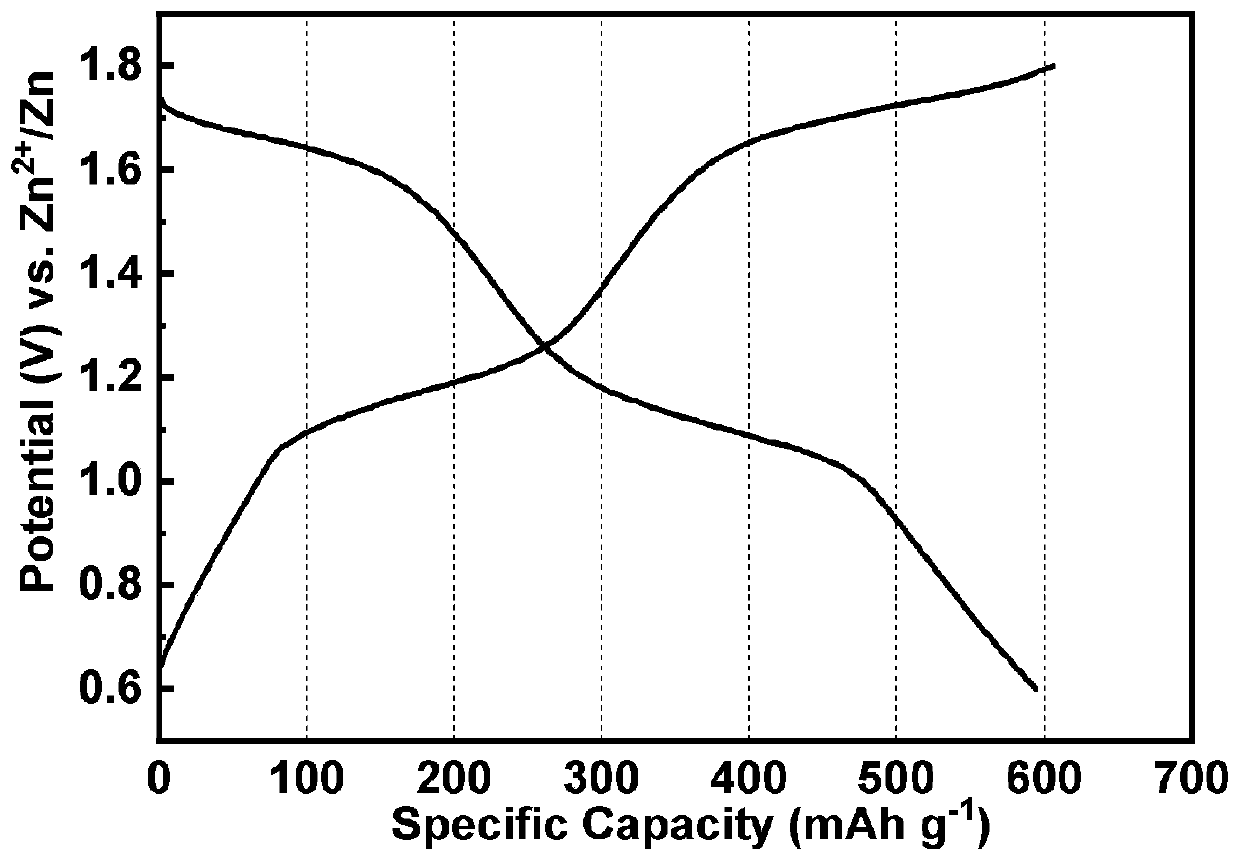

[0072] Add 300mg of high specific surface area activated carbon and 100mg of elemental iodine into 20ml of deionized water and mix, seal and heat to 60°C for 12h, then centrifuge the suspension at 5000 rpm, discard the supernatant, and heat-treat the lower mixture in an oven at 60°C After 12h, the iodine-activated carbon complex was obtained as the active material. The active material, SuperP, and CMC were mixed in a mass ratio of 8:1:1 and added with water to grind into a slurry, which was coated on a titanium foil and dried at 60°C to obtain a positive electrode sheet. The negative pole is a clean zinc flake. Electrolyte is ZnCl 2 :LiCl:ACN:H 2 O The aqueous solution (ZnCl 2 Molar concentration is 19M; LiCl molar concentration is 19M; ACN molar concentration is 8M). Assemble into a Swagelok battery. at 400mAg -1 The charge-discharge curve at current density is shown in figure 1 .

Embodiment 1-1

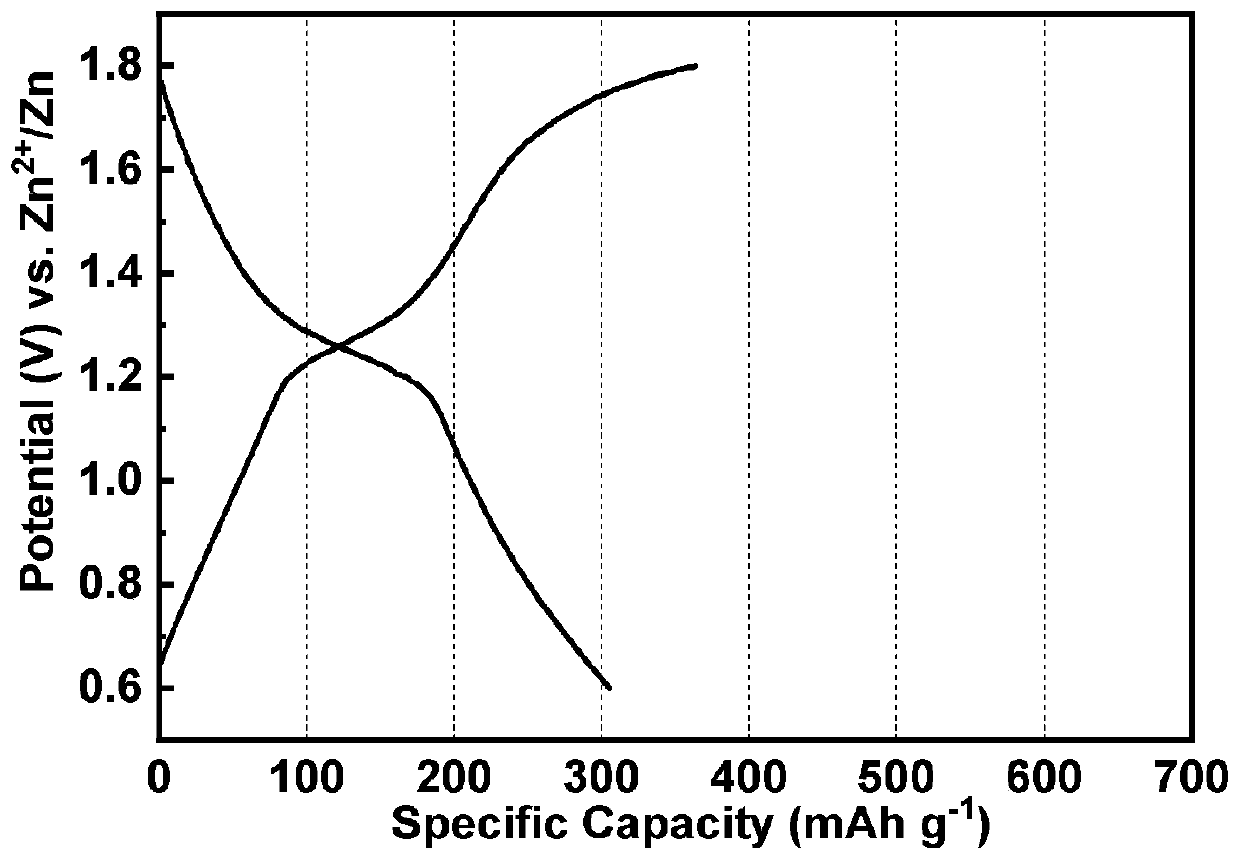

[0076] Compared with Example 1, the difference is that the electrolyte is pure zinc chloride aqueous solution: 10MZnCl 2 ; The rest of the steps are the same; at 400mAg -1 The charge-discharge curve at current density is shown in image 3 .

Embodiment 1-2

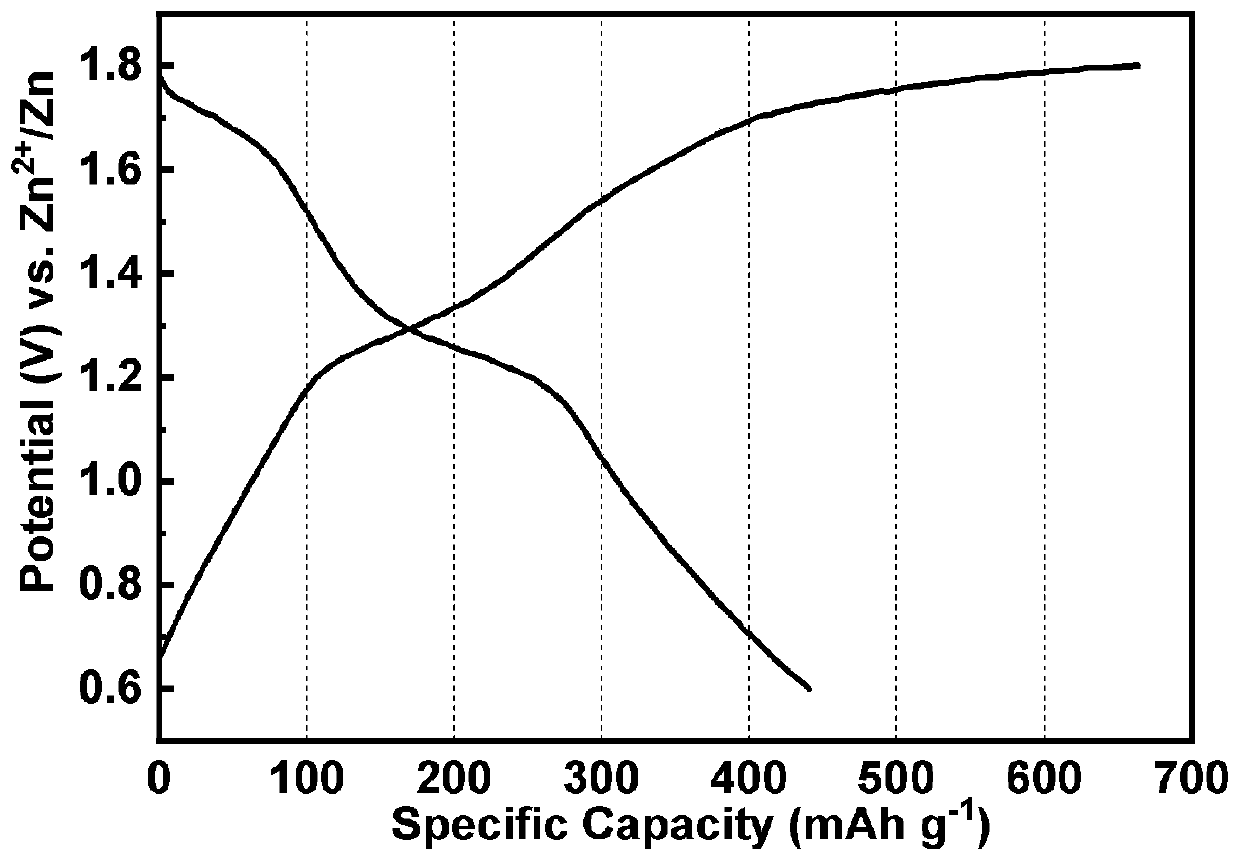

[0078] Compared with Example 1, the difference is that the electrolyte is 1MZnSO4+10MLiCl aqueous solution (changing the Zn source). at 400mAg -1 The charge-discharge curve at current density is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility in water | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com