Centrifugal compound roller surface high-temperature-resistant coating and production process thereof

A centrifugal compounding and production process technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of easy peeling of the coating, roll area bumps, low coating adhesion, etc., and achieve excellent adhesion and fast curing , slow down the corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

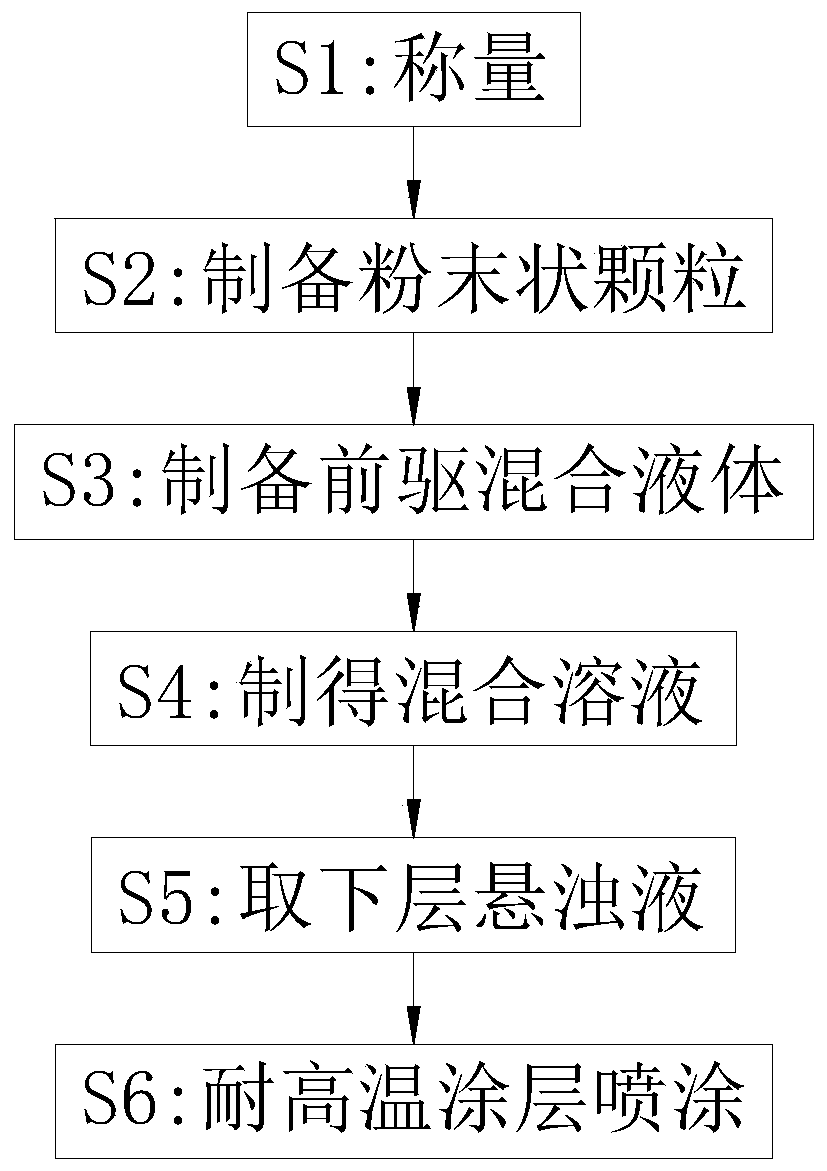

[0022] see figure 1 A high-temperature-resistant coating on the surface of a centrifugal composite roller, comprising the following ingredients in proportion by weight: tungsten carbide, cobalt base, boron nitride, chromium, cohesion reducing agent and solvent, the content of tungsten carbide is 20-38%, The cobalt base is 5-23%, the boron nitride is 7-15%, the chromium is 12-16%, the cohesion reducing agent is 7-11%, and the solvent is 15-25%. The solvent is DMF, TOL, MEK, EAC , IPA and water, the cohesion reducing agent is a low molecular weight polymer, such as aldehyde ketone resin and low molecular PE wax;

[0023] Tungsten carbide black hexagonal crystal, metallic luster, hardness similar to diamond, good conductor of electricity and heat, cobalt-based alloy, is a kind of cemented carbide resistant to various types of wear and corrosion and high temperature oxidation, cobalt-based The alloy is mainly composed of cobalt, containing a considerable amount of nickel, chromiu...

Embodiment 2

[0032] The content of tungsten carbide is 25-30%, cobalt base is 10-17%, boron nitride is 11-13%, chromium is 13-15%, cohesion reducing agent is 8-10% and solvent is 16-20%. .

[0033] Step 1: Accurately weigh each component: weigh 20-38% of tungsten carbide, 5-23% of cobalt base, 7-15% of boron nitride, 12-16% of chromium according to the proportion, reduce cohesion The auxiliary agent is 7-11% and the solvent is 15-25%;

[0034] Step 2: Pour tungsten carbide, cobalt base, and chromium into the reaction kettle, raise the temperature to 1300-1350°C, liquefy tungsten carbide, cobalt base, boron nitride, and chromium into molten metal at high temperature, and assemble the molten metal to high pressure In the atomization tower, under the action of high pressure, the metal liquid and the inert gas meet at the nozzle, and form powder particles after cooling. By increasing the atomization pressure, the speed of its atomization airflow is increased, and its surface and dynamic balan...

Embodiment 3

[0040] The content of tungsten carbide is 28%, cobalt base 14%, boron nitride 12%, chromium 14%, cohesion reducer 9% and solvent 18%.

[0041] Step 1: Accurately weigh each component: weigh 20-38% of tungsten carbide, 5-23% of cobalt base, 7-15% of boron nitride, 12-16% of chromium according to the proportion, reduce cohesion The auxiliary agent is 7-11% and the solvent is 15-25%;

[0042] Step 2: Pour tungsten carbide, cobalt base, and chromium into the reaction kettle, raise the temperature to 1300-1350°C, liquefy tungsten carbide, cobalt base, boron nitride, and chromium into molten metal at high temperature, and assemble the molten metal to high pressure In the atomization tower, under the action of high pressure, the metal liquid and the inert gas meet at the nozzle, and form powder particles after cooling. By increasing the atomization pressure, the speed of its atomization airflow is increased, and its surface and dynamic balance are destroyed. Complete secondary atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com