Optimized operation method of integrated sewage treatment equipment

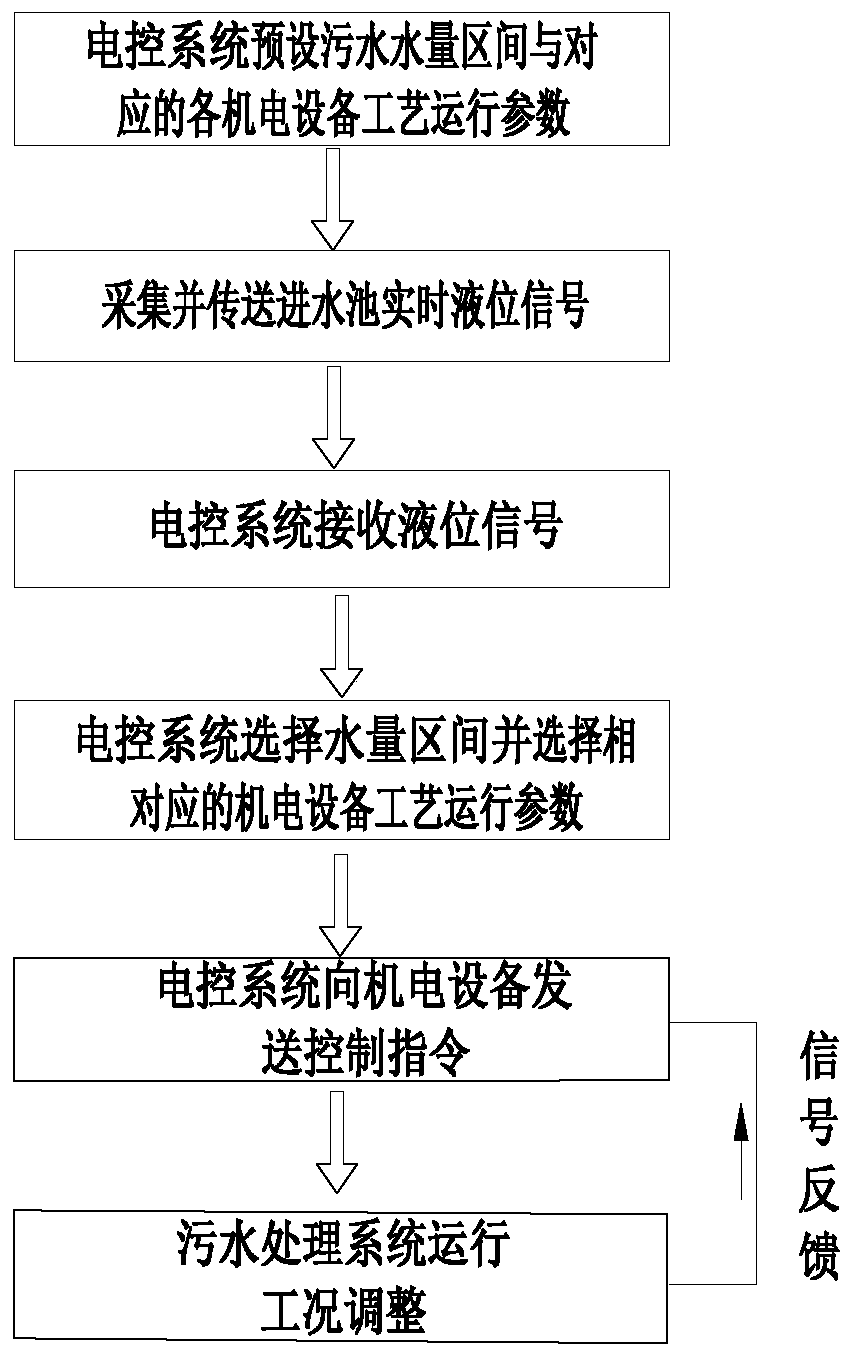

A kind of sewage treatment equipment and technology for optimized operation, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Insufficient and low water consumption for residents, etc., to overcome the wide fluctuation of influent water volume, to facilitate long-term stable operation, and to achieve the effect of good effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

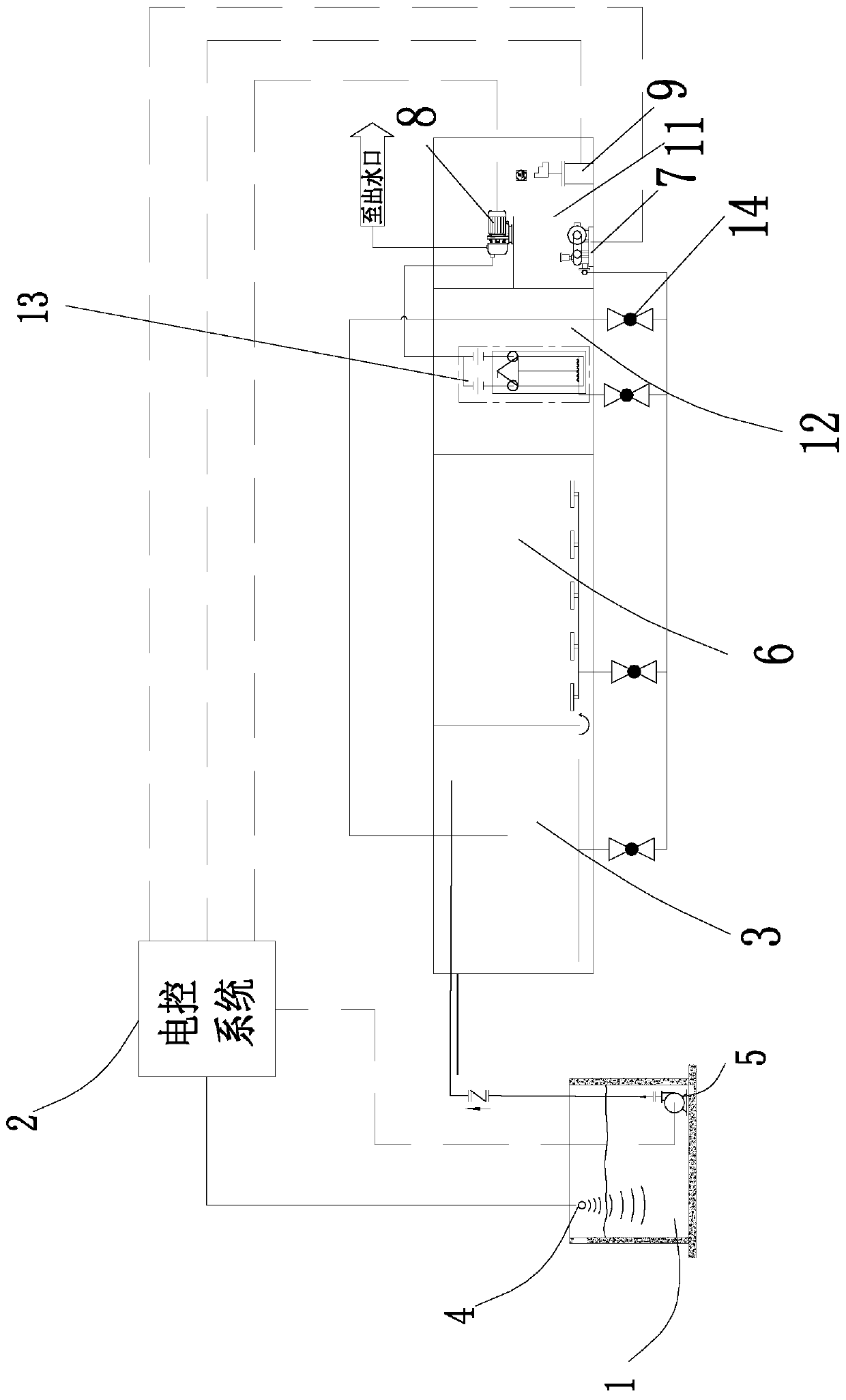

[0048] The integrated sewage treatment equipment of this embodiment is MBR integrated equipment, as attached figure 2 As shown, it includes: electronic control system 2, liquid level signal acquisition and feedback system connected with electronic control system 2, and sewage treatment system. The sewage treatment system mainly includes biochemical area and mud-water separation area. The mud-water separation area adopts membrane filtration, and sewage treatment The electromechanical equipment of the system is connected with the electric control system. Wherein the biochemical area includes the anoxic pool 3 and the aerobic pool 6 connected in sequence, the mud-water separation area includes the membrane pool 12, the membrane pool 12 is provided with the membrane module 13, and the liquid level signal collection and feedback system includes the liquid level probe 4 located in the water inlet pool 1 , The main electromechanical equipment includes the water inlet pump 5, the fir...

Embodiment 2

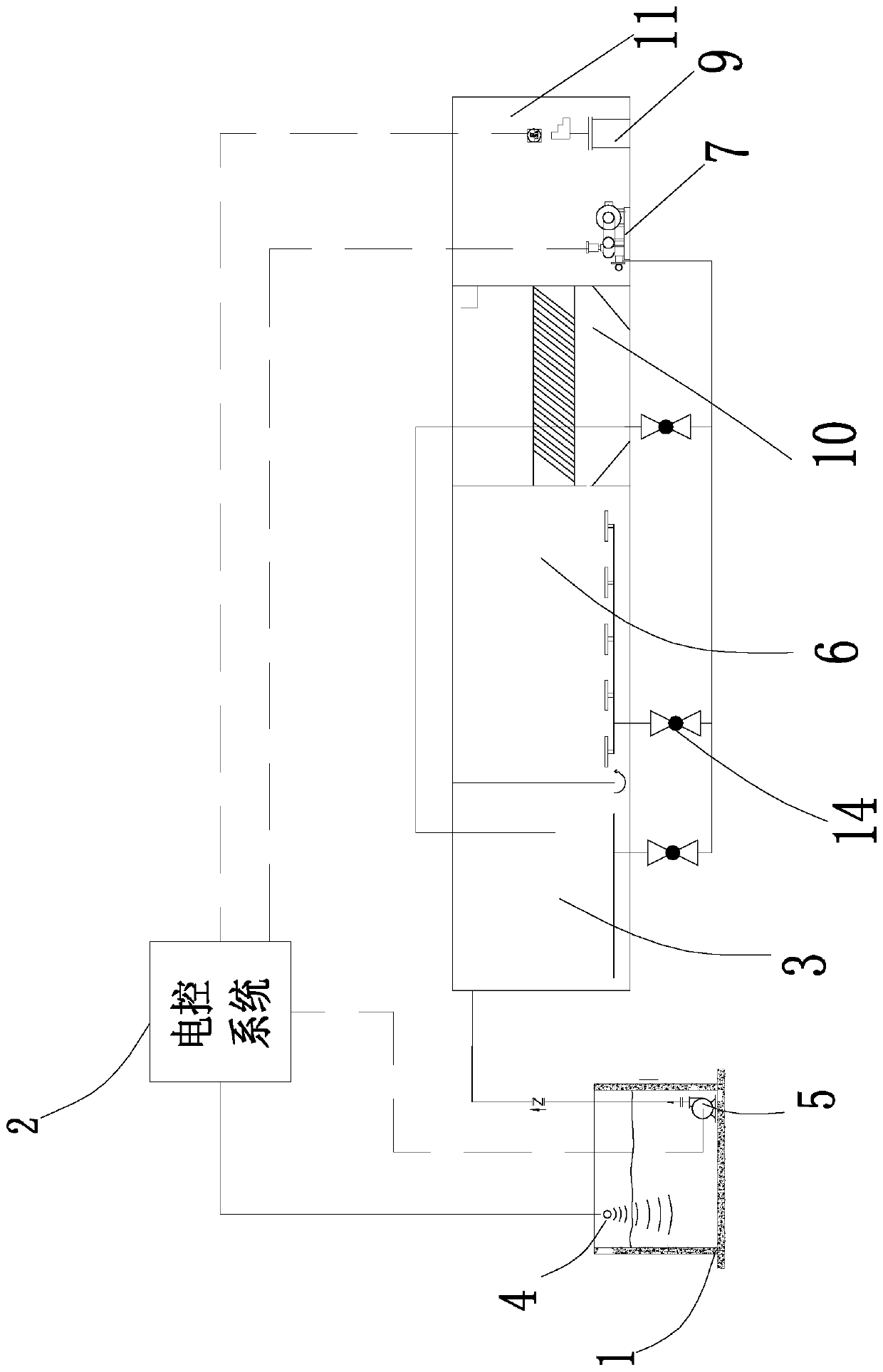

[0068] The integrated sewage treatment equipment of this embodiment is non-membrane integrated equipment, as attached image 3 As shown, it includes: electronic control system 2, liquid level signal acquisition and feedback system connected with electronic control system 2, and sewage treatment system. The sewage treatment system mainly includes biochemical area and mud-water separation area. The electromechanical equipment of the processing system is connected with the electric control system. The biochemical area includes anoxic pool 3 and aerobic pool 6, the mud-water separation area includes a sedimentation tank 10, the liquid level signal acquisition and feedback system includes a liquid level probe 4 located in the water inlet pool 1, and the main electromechanical equipment includes an inlet pump 5, a first The fan 7, the flocculant dosing pump 9, wherein the water inlet pump 5 is located in the water inlet tank 1, the first fan 7, the flocculant dosing pump 9 is locate...

Embodiment 3

[0074] The integrated sewage treatment equipment in this embodiment is an integrated equipment with double separation process, as attached Figure 4 As shown, the difference from Example 1 is that the mud-water separation zone adopts two modes of sedimentation tank separation and membrane filtration, and the anoxic tank 3 and the aerobic tank 6 are followed by a sedimentation tank 10, and the anoxic tank 3 and the aerobic tank 6 A manual valve 14 is installed on the aeration device for the backflow of the sedimentation tank 10 and the backflow of the membrane tank 12 . The integrated double separation process equipment includes sedimentation tank water outlet and membrane water outlet. The main electromechanical equipment includes: water inlet pump 5, first fan 7, flocculant dosing pump 9, water production pump 8, membrane aeration branch automatic valve 15.

[0075] The other steps of an integrated sewage treatment equipment optimization operation method are the same as those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com