Wood frog oil polysaccharide component and application thereof

A technology of Rana Rana oil and polysaccharide, which is applied to medical preparations, drug combinations, organic active ingredients and other directions containing active ingredients, can solve problems such as insufficient research on Rana Rana oil polysaccharides, etc., and can increase the generation of nitric oxide (NO) The effect of enhancing the phagocytic ability of macrophages, good safety profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Extraction and Purification of Rana Oil Crude Polysaccharide

[0033]With reference to the method mentioned in Yang Jing's master's degree thesis (extraction conditions optimization of crude polysaccharides from Rana Rana oil and research on its pharmacological activity, Jilin Agricultural University, 2011), weigh 10g of Rana Rana Oil defatted powder, and use a liquid-to-material ratio of 100:1 Soak in distilled water for 12 hours, homogenize, adjust pH to 6.8, add Rana oil degreasing powder 0.2% w / w papain and incubate at 37°C for 2 hours; inactivate enzyme in boiling water bath for 10 minutes, cool and centrifuge to take supernatant, adjust pH to 7.0, concentrated volume to 1 / 4, add 3 times the volume of 95V% ethanol aqueous solution, stand at 4°C for 12 hours; centrifuge to collect the precipitate, and freeze-dry to obtain the crude polysaccharide of Rana oil, with a yield of 5.09±0.21%, The total sugar content is 23.08±1.56%. The crude polysaccharide was ...

Embodiment 2

[0034] Example 2 Separation of Rana Oleopolysaccharide Components

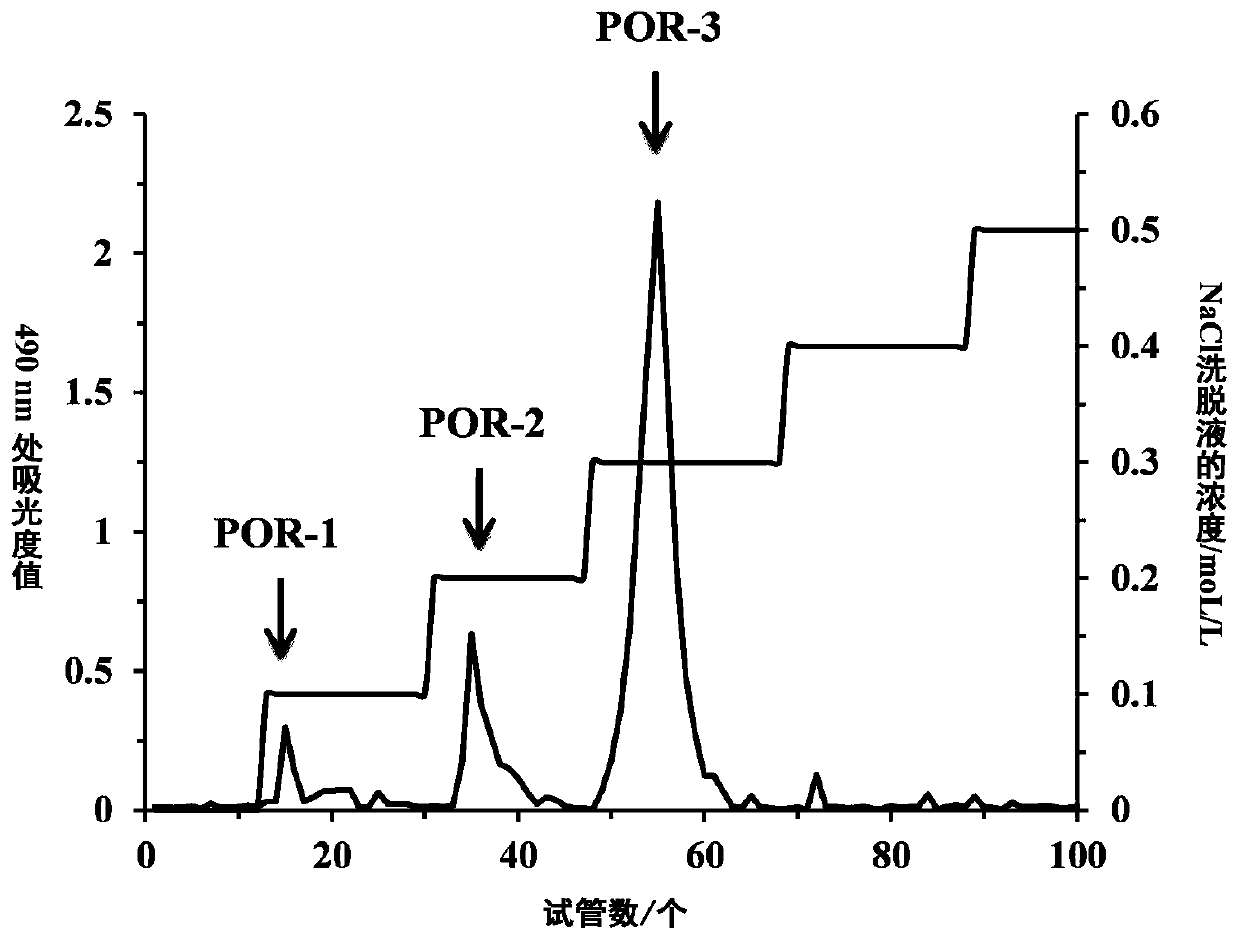

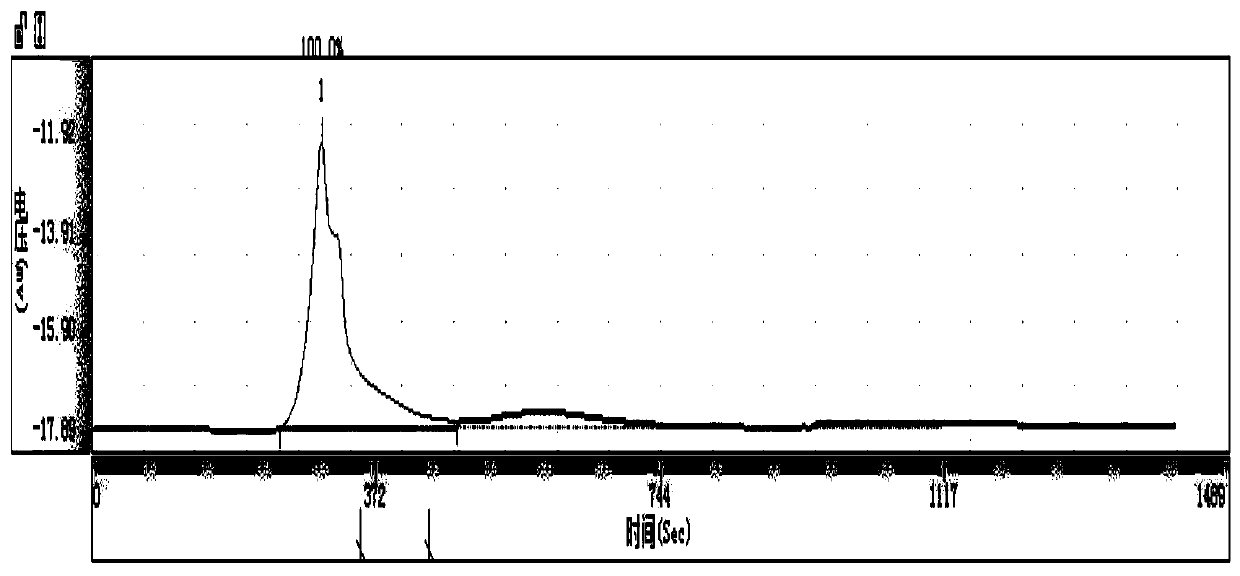

[0035] Weigh 100 mg of the purified polysaccharide from Rana oil, dissolve it in 20 mL of deionized water, and load it onto a DEAE cellulose-52 chromatographic column (2.6 cm × 60 cm); Gradient elution was performed at a flow rate of 1 mL / min, 5 mL per tube; the absorbance at a wavelength of 490 nm was detected by the phenol-sulfuric acid method, and the elution curve was drawn. Such as figure 1 As shown, when different concentrations of NaCl solutions are used for gradient elution, three elution peaks are obtained respectively, that is, the elution peaks POR-1 to 3 corresponding to the elution of 0.1mol / L to 0.3mol / L NaCl solution; Collect and combine the eluents corresponding to POR-1~3 respectively to obtain POR-1 (0.1mol / L NaCl solution), POR-2 (0.2mol / L NaCl solution), POR-3 (0.3mol / L NaCl solution) of the three polysaccharide fractions; dialyze the three polysaccharide fractions three times with deioni...

Embodiment 3

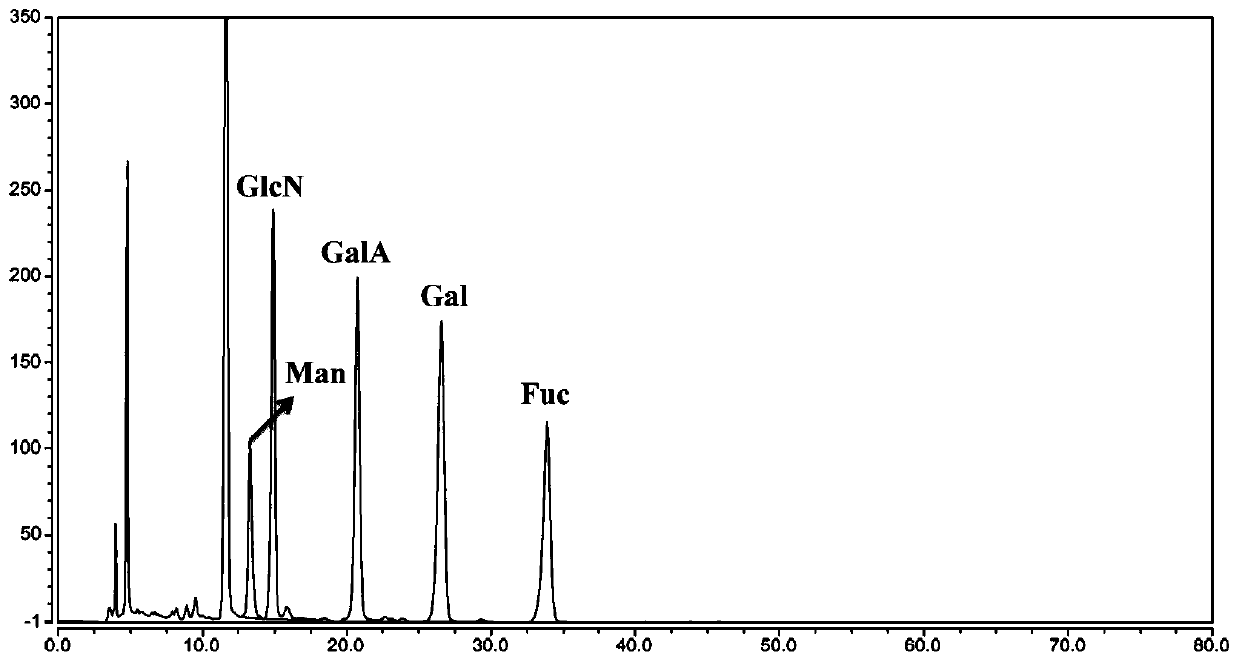

[0036] Example 3 Composition Analysis and Antioxidant Activity Comparison of Rana Oil Polysaccharide Components

[0037] The total sugar content of each polysaccharide component is measured using the phenol-sulfuric acid method (Anal.Chem.28 (3) (1956) 350-356); the protein content is measured using the Coomassie Brilliant Blue method (Anal.Biochem.72 (1976) 248- 254); the content of uronic acid was determined by m-hydroxybiphenyl method (Anal.Biochem.54(2)(1973)484-489).

[0038] Determination of hydroxyl radical scavenging rate: Take 2mL polysaccharide component solutions with different concentrations (0.2mg / mL~1.0mg / mL), 1mL phosphate buffer (pH 7.4) containing 0.75mmol / L phenanthroline and 1mL 0.75mmol / L FeSO 4 solution, mix well, then add 1mL of 0.12% H 2 o 2 The solution was used to initiate the reaction, incubated at 37°C for 60 min, and the absorbance value at 536 nm was measured. The sample control tube is distilled water instead of the sample, and the sample back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com