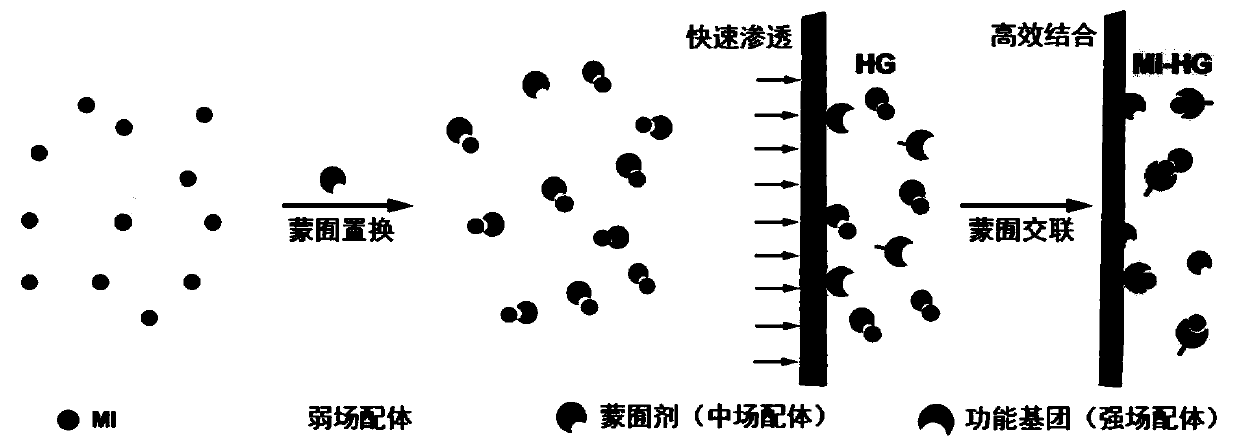

Method for enhancing mechanical strength of hydrogel based on masking strategy

A mechanical strength, hydrogel technology, applied in the field of enhancing the mechanical strength of hydrogels based on the masking strategy, can solve the uneven improvement of MI-HG mechanical strength, the insignificant enhancement of MI-HG mechanical strength, and the difficulty of molecular size and charge. improvement and other issues, to achieve the effect of increasing the masking effect, being suitable for promotion, and increasing the molecular size and the number of charges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, the preparation of PVA-PAA hydrogel precursor

[0033] Step 101. Dissolve 2 parts of polyvinyl alcohol in 30 parts of deionized water in parts by mass, then raise the temperature to 70°C and stir for 2 hours, then cool to 20°C to obtain a clear and transparent PVA aqueous solution; the molecular weight of the polyvinyl alcohol m w =205,000;

[0034] Step 102, adding 10 parts of acrylic acid monomer and 0.045 parts of 2,4-dihydroxybenzophenone to the PVA aqueous solution obtained in step 101 in parts by mass, and then stirring at 20°C for 20 minutes to obtain PVA- AA mixture;

[0035] Step 103. Put the PVA-AA mixture obtained in step 102 under vacuum for 10 minutes, then pour it into a glass mold, and perform ultraviolet curing to polymerize the acrylic acid monomer to obtain a PVA-PAA hydrogel with a thickness of 1 mm. Glue precursor; the size of the glass mold is 5cm×5cm (length×width); the ultraviolet light used in the ultraviolet curing has a wavelength of...

Embodiment 2

[0051] Step 1, the preparation of PVA-PAA hydrogel precursor

[0052] Step 101. Dissolve 5 parts of polyvinyl alcohol in 100 parts of deionized water in parts by mass, then raise the temperature to 80°C and stir for 1.5h, then cool to 23°C to obtain a clear and transparent PVA aqueous solution; the polyvinyl alcohol Molecular weight M w =205,000;

[0053] Step 102, adding 60 parts of acrylic acid monomer and 0.2 part of α-ketoglutaric acid in parts by mass to the PVA aqueous solution obtained in Step 101, and then stirring at 23° C. for 25 minutes to obtain a PVA-AA mixed solution;

[0054] Step 103. Put the PVA-AA mixture obtained in step 102 under vacuum for 15 minutes, then pour it into a glass mold, and perform ultraviolet light curing to polymerize the acrylic acid monomer to obtain a PVA-PAA hydrogel with a thickness of 3 mm. Glue precursor; the size of the glass mold is 5cm×5cm (length×width); the ultraviolet light used in the ultraviolet curing has a wavelength of 36...

Embodiment 3

[0060] Step 1, the preparation of PVA-PAA hydrogel precursor

[0061] Step 101. Dissolve 8 parts of polyvinyl alcohol in 200 parts of deionized water in parts by mass, then raise the temperature to 90°C and stir for 1 hour, then cool to 25°C to obtain a clear and transparent PVA aqueous solution; the molecular weight of the polyvinyl alcohol m w =205,000;

[0062] Step 102: Add 100 parts by mass of acrylic acid monomer and 0.45 parts of α-hydroxyalkyl phenone to the PVA aqueous solution obtained in Step 101, and then stir at 25°C for 30 minutes to obtain a PVA-AA mixed solution ;

[0063] Step 103, put the PVA-AA mixture obtained in step 102 under vacuum for 20 minutes, then pour it into a glass mold, and perform ultraviolet light curing to polymerize the acrylic acid monomer to obtain a PVA-PAA hydrogel with a thickness of 4 mm. Glue precursor; the size of the glass mold is 5cm×5cm (length×width); the ultraviolet light used in the ultraviolet curing has a wavelength of 365...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com